Polymer cement-based composite protection material for nuclear power projects, and preparation method thereof

A protective material and nuclear power engineering technology, applied in the field of nuclear power engineering, can solve problems such as ineffective radiation protection, and achieve the effects of good protection, excellent dispersion and stability, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

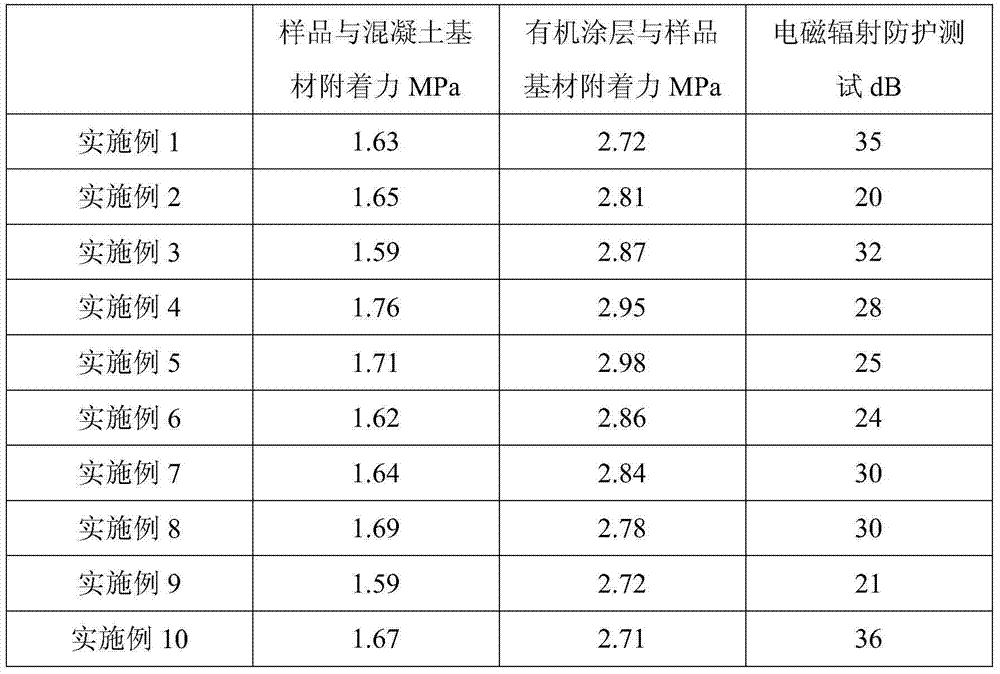

Examples

Embodiment 1

[0047] To prepare the polymer cement-based composite protective material of the present invention, the steps are as follows:

[0048] (1) Preparation of liquid material components: sequentially add 400 g of elastic carboxyl-containing acrylate emulsion, 200 g of elastic carboxyl-containing styrene-acrylate emulsion, and 50 g of elastic carboxyl-containing siloxane-acrylate emulsion into the stirring reaction kettle, and / min stirring speed and stirring for 30min, disperse 1g of liquid dispersant AMP-95, 1g of defoamer BYK019, 10g of plasticizer DOP into 338g of water, and then dissolve the water with dispersant, defoamer and plasticizer in 5ml Add dropwise to the stirring reaction kettle at a speed of / s, and discharge after stirring for 30 minutes after the dropwise addition, to obtain the liquid material component of the polymer cement-based composite protective material;

[0049] (2) Preparation of powder components: First, 50g of multi-walled carbon nanotubes and 150g of h...

Embodiment 2

[0052] To prepare the polymer cement-based composite protective material of the present invention, the steps are as follows:

[0053] (1) Preparation of liquid material components: sequentially add 400 g of elastic carboxyl-containing acrylate emulsion, 400 g of elastic carboxyl-containing styrene-acrylate emulsion, and 150 g of elastic carboxyl-containing siloxane-acrylate emulsion into the stirring reaction kettle, / min stirring speed and stirring for 30min, disperse 3g of liquid dispersant Silok7110, 4g of defoamer BYK019, 10g of plasticizer DBP into 33g of water, and then dissolve the water with dispersant, defoamer and plasticizer at 10ml / s Add it dropwise to the stirring reaction kettle at a high speed, and then discharge after stirring for 30 minutes after the dropwise addition, to obtain the liquid material component of the polymer cement-based composite protective material;

[0054] (2) Preparation of powder components: first, 5g single-walled carbon nanotubes and 50g...

Embodiment 3

[0057] To prepare the polymer cement-based composite protective material of the present invention, the steps are as follows:

[0058] (1) Preparation of liquid material components: successively add 700 g of elastic carboxyl-containing acrylate emulsion, 200 g of elastic carboxyl-containing styrene-acrylate emulsion, and 50 g of elastic carboxyl-containing siloxane-acrylate emulsion into the stirring reaction kettle, / min Stirring speed and stirring for 30min, disperse 1g of liquid dispersant TEGO761, 1g of defoamer BYK028, 30g of plasticizer DOP into 18g of water, and then dissolve the water with dispersant, defoamer and plasticizer at 5ml / s Add it dropwise to the stirring reaction kettle at a high speed, and then discharge after stirring for 30 minutes after the dropwise addition, to obtain the liquid material component of the polymer cement-based composite protective material;

[0059] (2) Preparation of powder components: first, 50g of multi-walled carbon nanotubes and 50g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com