Method for preparing nano needle-shaped purple tungsten powder

A nanoneedle and violet tungsten technology, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of insufficient phase purity of reaction products, long-term reaction, and low quality of violet tungsten, and achieve High surface activity, good dispersibility, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

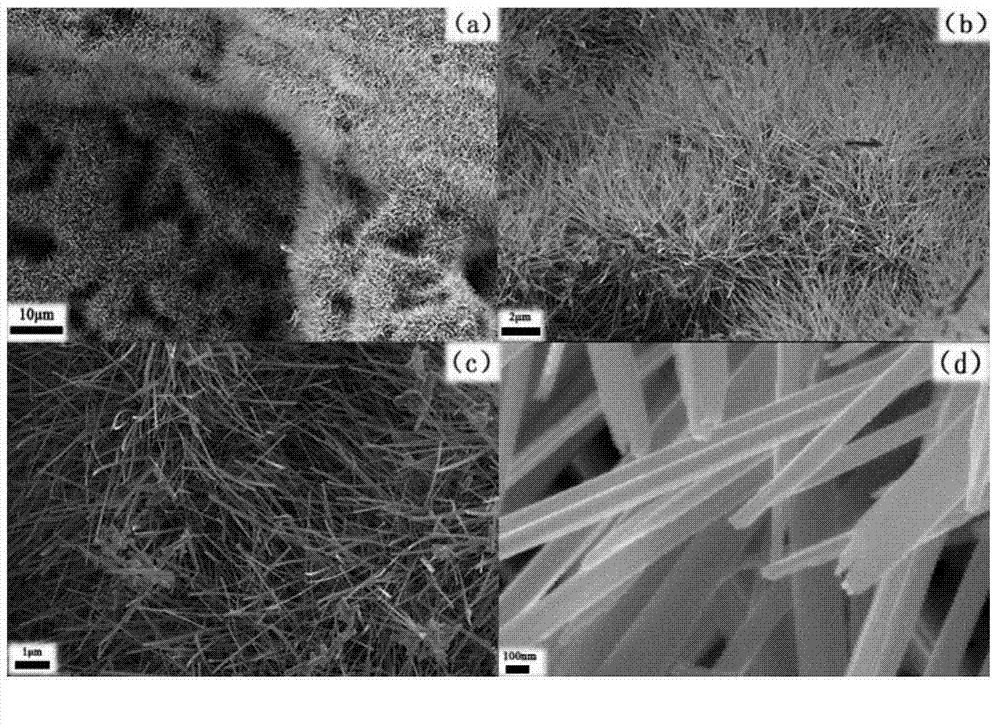

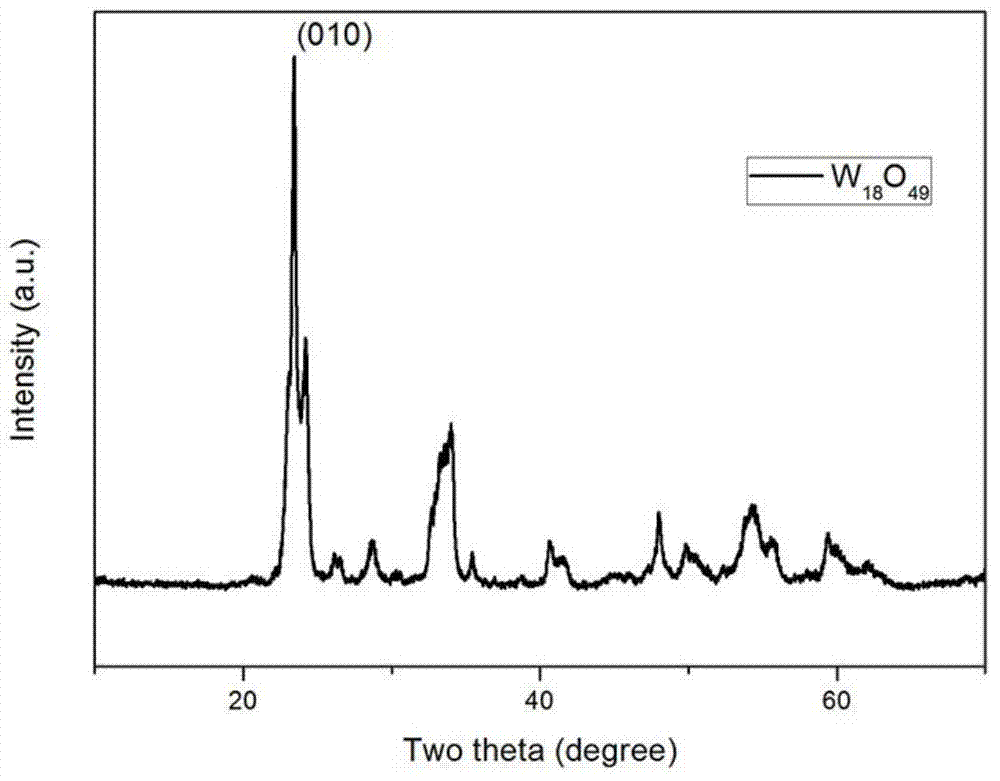

[0020] Weigh ammonium metatungstate ((NH 4 ) 6 h 2 W 12 o 40 )0.01mol, ammonium nitrate (NH 4 NO 3 )0.24mol, thiourea (CN 2 h 4 S) 0.05mol. Dissolve the raw material powder in an appropriate amount of deionized water and stir until it is completely dissolved, then heat at a constant temperature of 200°C. After the solution is evaporated to dryness, a violent redox reaction occurs within tens of seconds, releasing a large amount of gas to form violet tungsten. The obtained powder is in the shape of nano needles, with a diameter of 30-100 nm and a length of 0.5-5 μm.

Embodiment 2

[0022] Weigh ammonium metatungstate ((NH 4 ) 6 h 2 W 12 o 40 )0.01mol, ammonium nitrate (NH 4 NO 3 ) 0.36mol, thiourea (CN 2 h 4 S) 0.05mol. Dissolve the raw material powder in an appropriate amount of deionized water and stir until it is completely dissolved, then heat at a constant temperature of 200°C, and after the solution is evaporated to dryness, a violent redox reaction occurs within tens of seconds to release a large amount of gas to form violet tungsten. The obtained powder is in the shape of nano needles, with a diameter of 70-150 nm and a length of 0.5-3 μm.

Embodiment 3

[0024] Weigh ammonium metatungstate ((NH 4 ) 6 h 2 W 12 o 40 )0.01mol, ammonium nitrate (NH 4 NO 3 )0.36mol, urea (CO(NH 2 ) 2 )0.05mol. Dissolve the raw material powder in an appropriate amount of deionized water and stir until it is completely dissolved, then heat at a constant temperature of 200°C. After the solution is evaporated to dryness, a violent redox reaction occurs within tens of seconds, releasing a large amount of gas to form violet tungsten. The obtained powder is in the shape of nano needles, with a diameter of 20-75 nm and a length of 0.5-5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com