Coagulation-preventing circulation ink return system for gravure printing machine

An anti-condensation, gravure printing machine technology, applied in the direction of gravure rotary printing machine, printing machine, rotary printing machine, etc., can solve the problems of increasing enterprise cost, stagnation, slow flow of surface ink, etc., to achieve simple and reliable structure, ensure No modification, improvement effect of ink skin phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

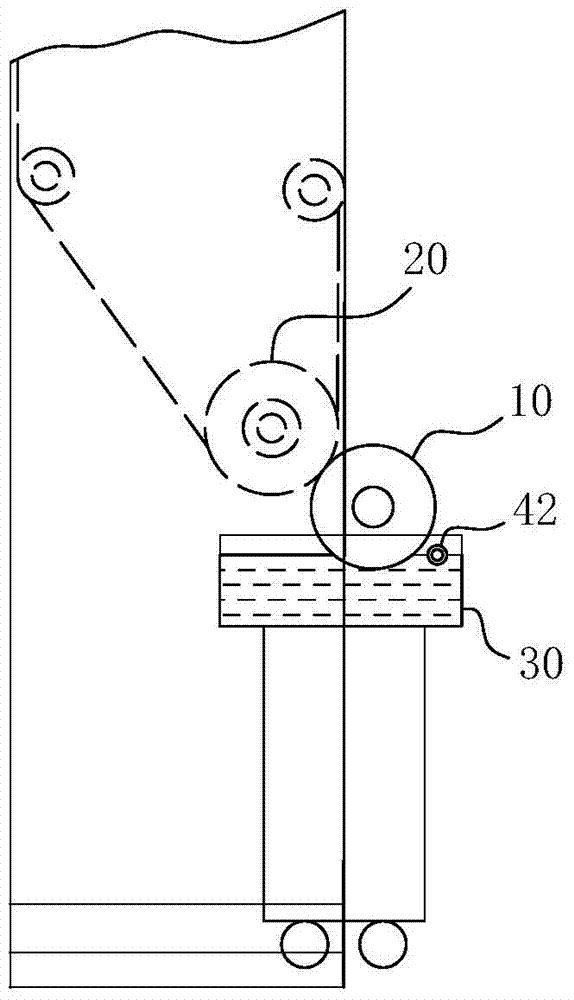

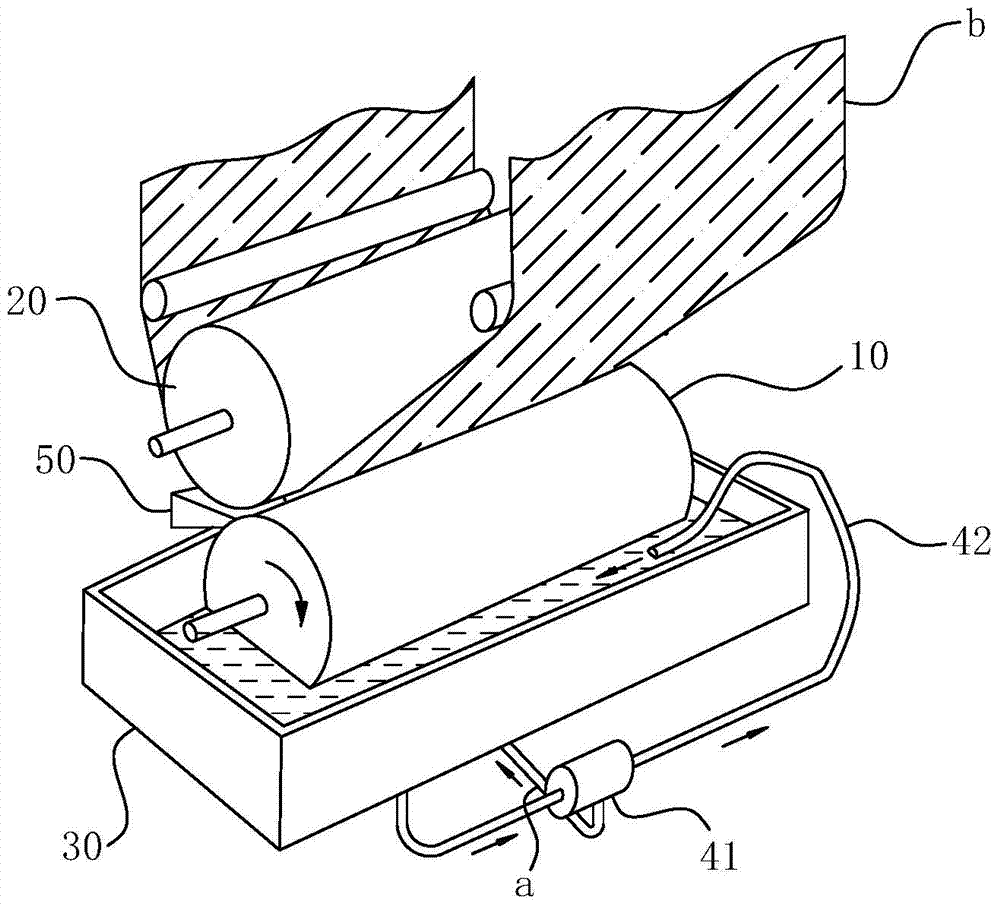

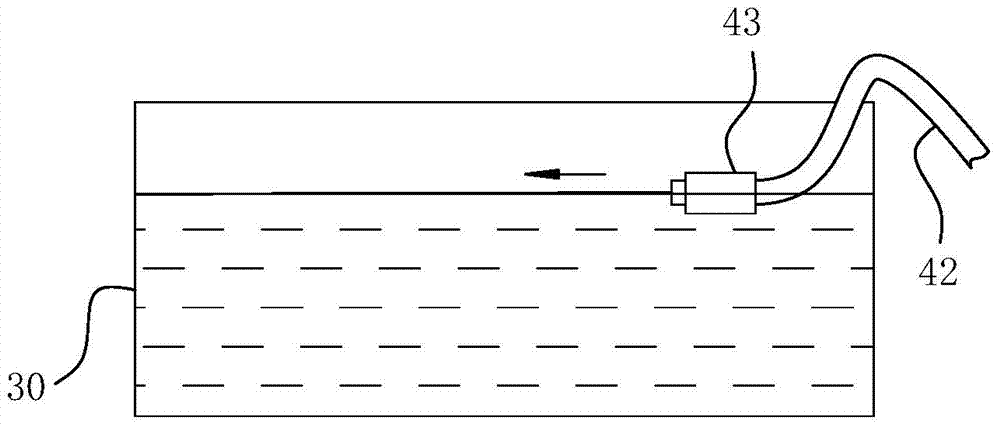

[0022] For ease of understanding, combined here Figure 1-5 Concrete structure of the present invention and working state are described further as follows:

[0023] The working structure of the present invention is as figure 1 As shown, it includes an ink tray 30 that is in the shape of a tank and can be placed on a base or a trolley. The hopper structure of the ink tray 30 constitutes a storage bin for storing ink. An inking roller 10 for cooperating with the embossing roller 20 of the gravure printing machine is erected above the opening of the ink tray 30 . Wherein the inking roller 10 is located below, and part of the roller surface can be set to be immersed below the ink surface of the ink tray 30 . The external ink is pumped in through the ink pump 41, and is directly sprayed on the surface of the ink delivery roller 10 through the ink outlet pipeline a connected to the outlet of the ink pump 41. First, the ink is smoothed evenly by the scraper 50 on the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com