Machining center using turntable type tool magazine

A machining center and tool magazine technology, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of limiting the application range of machining centers, increasing the equipment footprint, and wasting the travel of machining centers, so as to reduce equipment The effect of occupying an area, saving the stroke of the machining center, and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

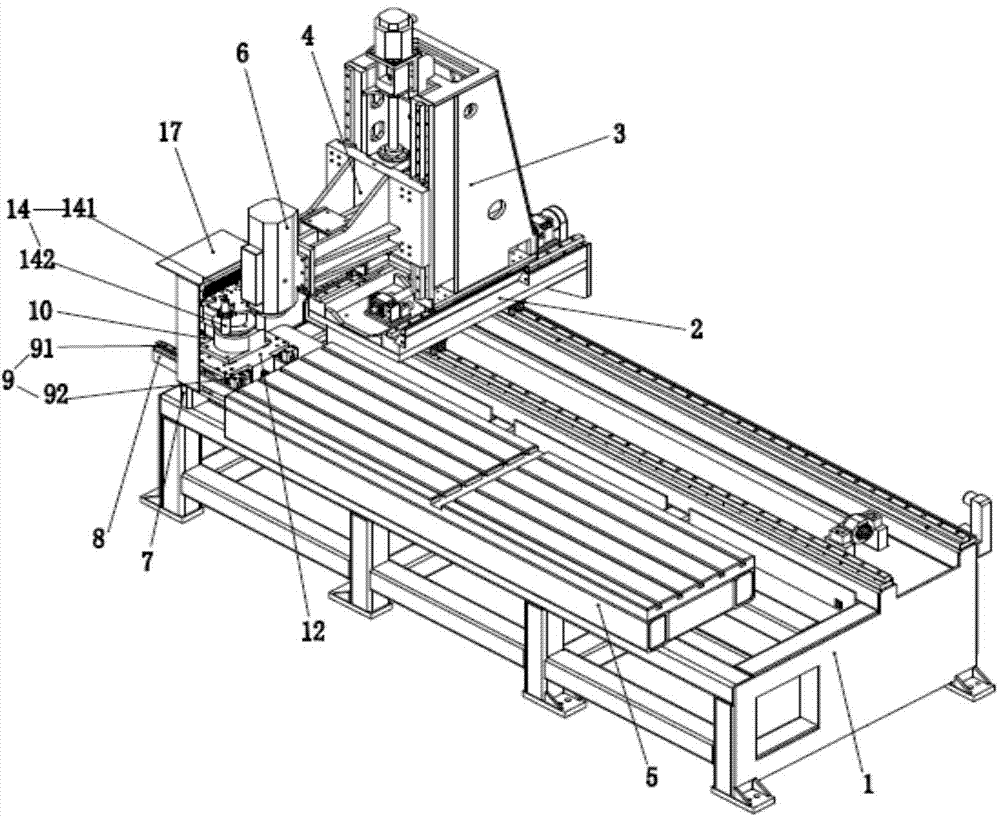

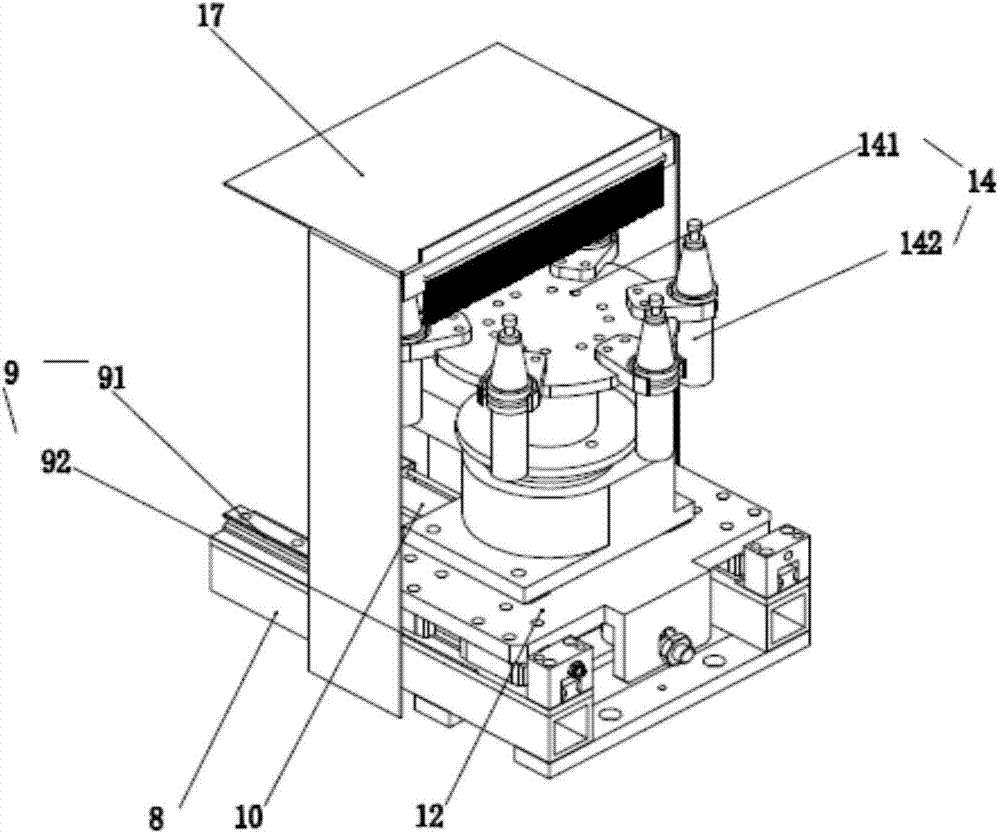

[0022] Such as figure 1 and figure 2 As shown, a machining center using a bucket hat tool magazine is characterized in that it includes a bed 1, a bed saddle 2, a column 3, a machine head 4, a workbench 5, a spindle 6, a tool magazine moving guide 9, and a tool magazine installation plate 12. Tool 14 and driving device 10;

[0023] The saddle 2 and the workbench 5 are installed on the bed 1, the column 3 is installed on the saddle 2, the machine head 4 is installed on the column 3; the main shaft 6 is installed on the on nose 4;

[0024] The tool magazine moving guide rail 9 is installed on the bed 1, and the tool magazine moving guide rail 9 and the worktable 5 are on the same side of the bed 1; the tool magazine mounting plate 12 is installed on the tool bed 1. On the magazine moving guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com