NaA type molecular sieve membrane synthesized on surface of organic hollow fiber, and production method thereof

A fiber surface and molecular sieve technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor combination of organic materials and inorganic materials, large performance differences, and low cost , excellent performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

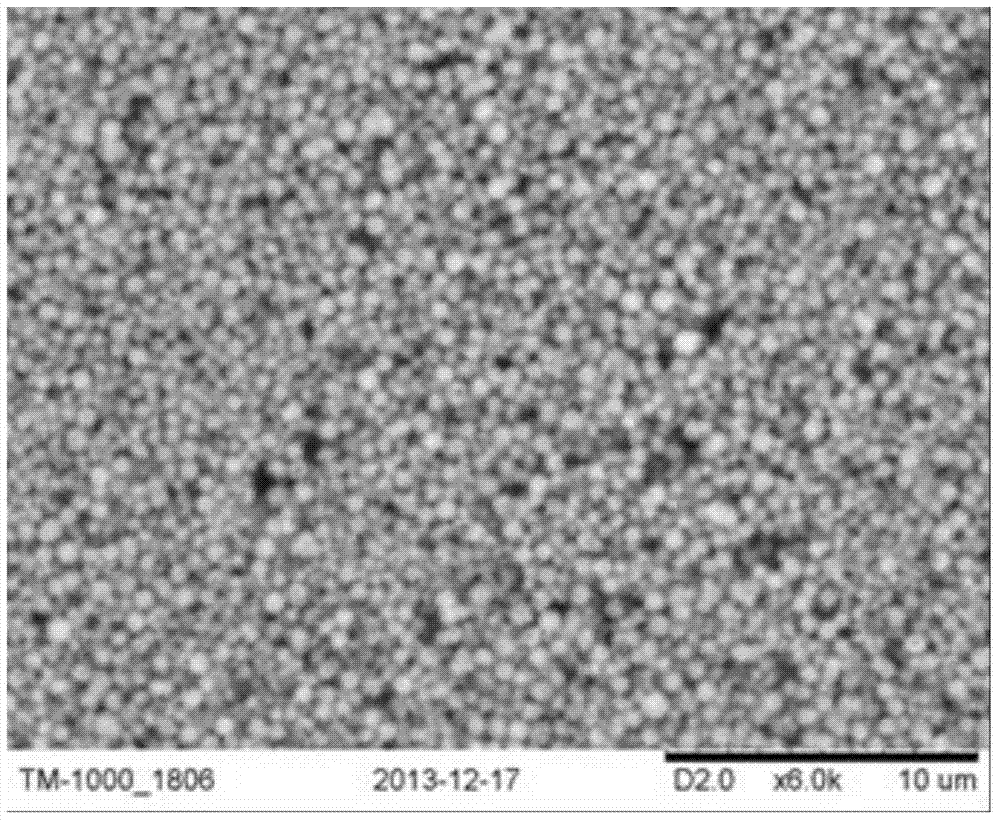

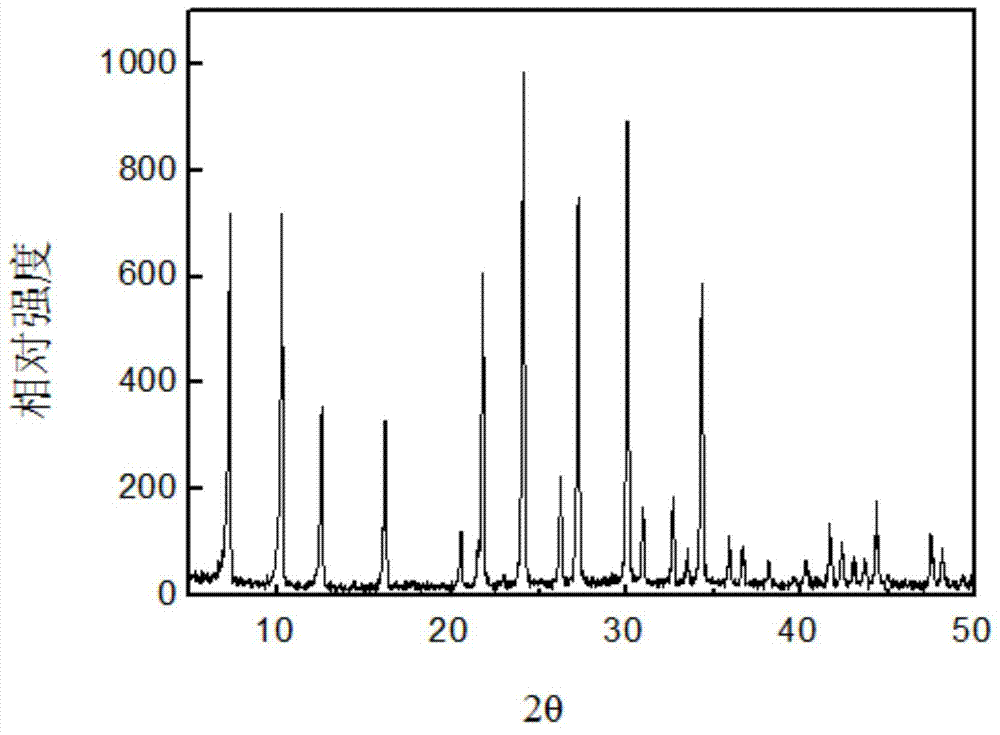

[0040] (1) Preparation of NaA type molecular sieve seed crystal:

[0041] Na in molar ratio 2 O: Al 2 o 3 :SiO2 2 :H 2 O=2.9:0.48:1:98 to prepare a synthetic solution, weigh a certain amount of sodium aluminate and dissolve it in deionized water, and take another certain amount of sodium hydroxide and sodium silicate and dissolve it in deionized water, and then dissolve the sodium aluminate The solution was added dropwise to the sodium silicate solution, and after aging for 24 hours, it was heated in a constant temperature water bath at 80°C for 3 hours. After the seed crystal is synthesized by the hydrothermal method, the synthetic solution is centrifuged and washed with deionized water until there is no adhesion of amorphous gel-like substances on the surface of the seed crystal. At this time, the pH value of the seed crystal suspension is 8-9, and after drying, the obtained Seed.

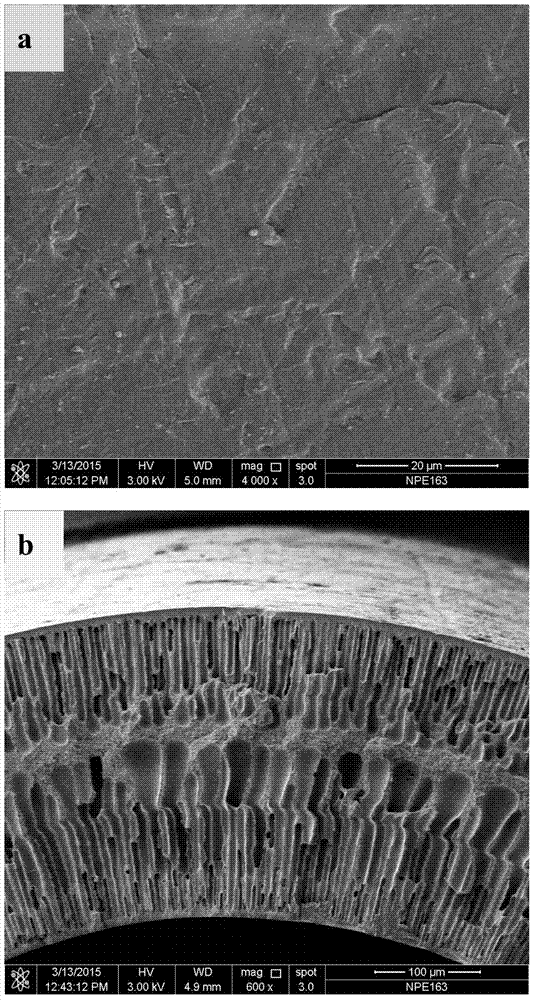

[0042] (2) Preparation of composite seed layer:

[0043] First prepare composite seed ...

Embodiment 2

[0051] (1) Preparation of NaA type molecular sieve seed crystal:

[0052] With embodiment 1.

[0053] (2) Preparation of composite seed layer:

[0054] First prepare composite seed coating liquid, weigh 1.40g PES and join in NMP and stir to dissolve, then weigh the seed crystals obtained in step (1) (by seed crystal and PES mass ratio is 65:35, 70:30, 75:25, 80:20, and 85:15 were weighed five times) and ultrasonically dispersed to obtain a uniformly dispersed composite seed layer coating solution. Then, a composite seed layer is prepared by a dip coating method, and the organic hollow fiber membrane is immersed in the coating solution for 10 seconds, taken out, and dried at a low temperature to obtain a composite carrier.

[0055] (3) Preparation of NaA type molecular sieve membrane:

[0056] With embodiment 1.

[0057] Table 2 NaA molecular sieve membrane with PSF hollow fiber as support and PES / NaA composite middle layer added

[0058]

[0059]

[0060] As can be ...

Embodiment 3

[0062] (1) Preparation of NaA type molecular sieve seed crystal:

[0063] With embodiment 1.

[0064] (2) Preparation of composite seed layer:

[0065] First prepare composite seed coating liquid, weigh 1.40g PEI and join in 26.60g NMP and stir to dissolve, then weigh the seed crystals obtained in step (1) (by mass ratio of seed crystals and PEI is 65:35, 70: 30, 75:25, 80:20, and 85:15 were weighed five times) and ultrasonically dispersed to obtain a uniformly dispersed composite seed layer coating solution. Then, a composite seed layer is prepared by a dip coating method, and the organic hollow fiber membrane is immersed in the coating solution for 10 seconds, taken out, and dried at a low temperature to obtain a composite carrier.

[0066] (3) Preparation of NaA type molecular sieve membrane:

[0067] With embodiment 1.

[0068] Table 3 NaA molecular sieve membrane with PSF hollow fiber as support and PEI / NaA composite middle layer added

[0069]

[0070] From the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com