Condensation and adsorption type formaldehyde recycling device applied to artificial board manufacturing industry and recycling method

A technology for manufacturing industries and recycling devices, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of high operating costs, insufficient energy saving, and high failure rate of vacuum pressure swing adsorption, and achieve higher energy efficiency ratios and higher The effect of recycling efficiency, cost and failure rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

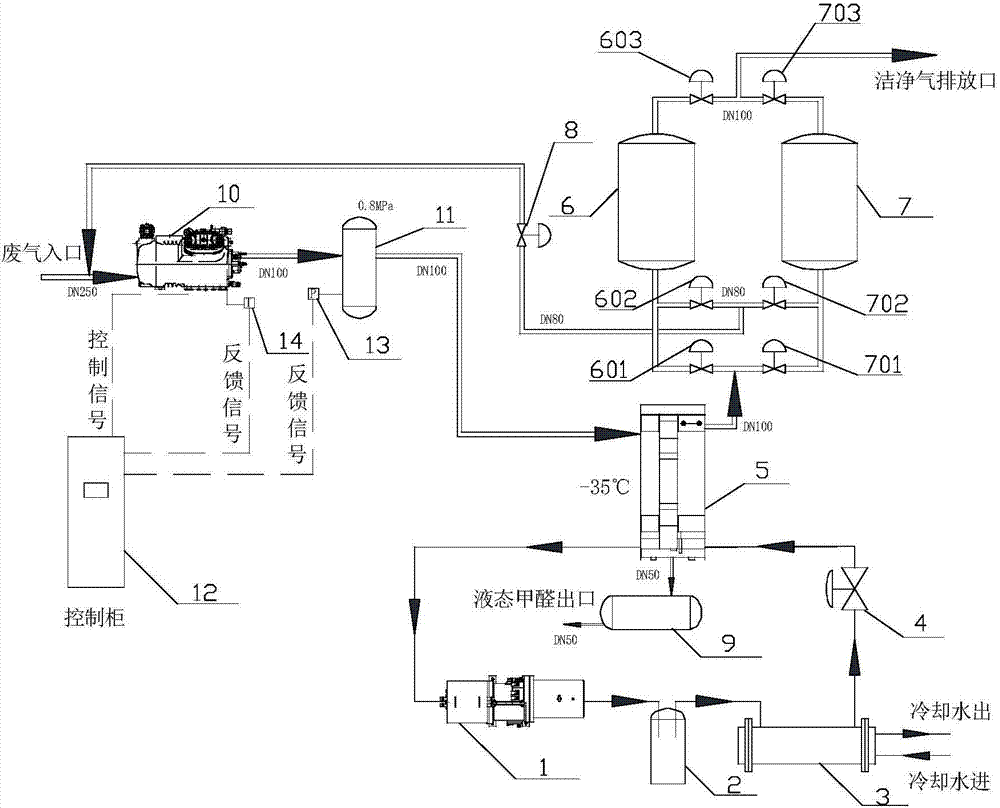

[0029] Embodiment 1: as figure 1 As shown, the condensation and adsorption type formaldehyde recovery device for the wood-based panel manufacturing industry described in this embodiment includes a semi-hermetic piston compressor 10, an air storage tank 11, two groups of adsorption units, a pneumatic valve 8 for circulation, a refrigeration circuit, Liquid storage tank 9, control cabinet 12; refrigeration circuit is composed of semi-hermetic screw refrigeration compressor 1, oil separator 2, water-cooled condenser 3, electronic expansion valve 4 and plate-fin evaporator 5; the first group of adsorption units includes Adsorption tank A 6, intake valve A 601, analytical valve A 602, air outlet valve A 603, the outlet of the formaldehyde channel of the plate-fin evaporator 5 is connected to the air inlet at the bottom of the adsorption tank A 6 through the intake valve A 601 , the gas outlet at the top of the adsorption tank A6 is connected to the clean gas discharge port through ...

Embodiment 2

[0031] Embodiment 2: The structure is basically the same as that of Embodiment 1, and the similarities will not be described again. The difference is that the pressurization passage also includes a control cabinet 12, and the control cabinet 12 is respectively connected to the air storage tank 11. The pressure sensor 13 of the semi-hermetic piston compressor 10 is electrically connected to the temperature sensor 14; the control cabinet 12 is also electrically connected to the bypass valve of the semi-hermetic piston compressor 10.

Embodiment 3

[0032]Embodiment 3: the recovery method of the condensate-adsorption type formaldehyde recovery device used in the wood-based panel manufacturing industry, comprising the following steps: 1. pressurized treatment step: formaldehyde gas enters the semi-hermetic piston compressor through the waste gas inlet, passes through the semi-closed The piston compressor is compressed into formaldehyde gas with a pressure of 0.7~0.8MPa;

[0033] ②Low-temperature condensation step: The pressurized formaldehyde gas passes through the gas storage tank and enters the plate-fin evaporator, and at the same time performs heat exchange treatment with the refrigerant flowing through the plate-fin evaporator. After being circulated and cooled by the refrigeration circuit, 90% ~95% of the formaldehyde gas is cooled to a liquid state, and is recovered by a liquid storage tank connected to the liquid outlet of the formaldehyde channel at the bottom of the plate-fin evaporator; the pressure of the formal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com