Automobile electric horn contact steel discs and processing method for same

A processing method and electric horn technology, applied in electrical components, sensors, etc., can solve problems such as hidden dangers of driving safety, long production cycle, corrosion pits, etc., and achieve the effect of prolonging life, moderate cost and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

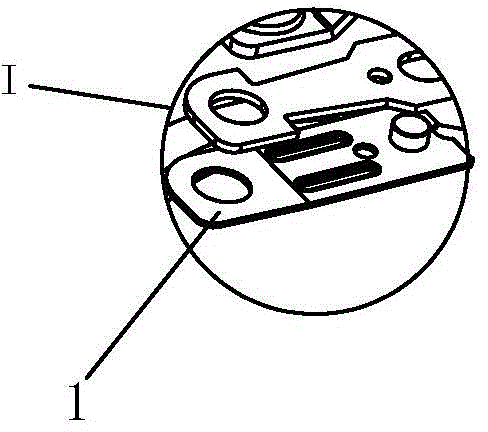

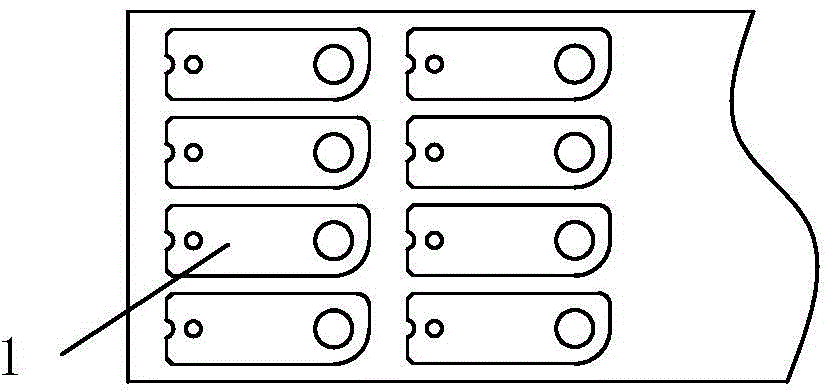

[0031] Now in conjunction with accompanying drawing, the present invention will be further described:

[0032] As shown in the figure, an automobile electric horn contact steel sheet, the two sides 11 of the contact steel sheet 1 are in the form of arc surfaces.

[0033] Arc faces are tangent to two faces that intersect.

[0034] Steel sheet 1 is stainless steel.

[0035] The hardness of stainless steel is HV370-540.

[0036] The roughness of the arc surface is less than Ra3.2.

[0037] The thickness of the contact steel sheet is 0.4mm-0.7mm.

[0038] Figure 7 Among them, the thickness of the contact steel sheet 1 is equal to twice the radius of the arc surface. That is, the arc surface is tangent to the two intersecting surfaces.

[0039] Figure 8 Among them, the thickness of the contact steel sheet 1 is greater than twice the radius of the arc surface, that is, a section between the two arc surfaces is a plane.

[0040] Figure 9 Among them, the thickness of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com