Double-phase driving synchronization method of cracking furnace tube outer wall temperature measurer

A driving method and technology of a thermometer, applied in the petrochemical industry, can solve the problems of severe disturbance, harsh working environment, and high temperature measurement environment, and achieve the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

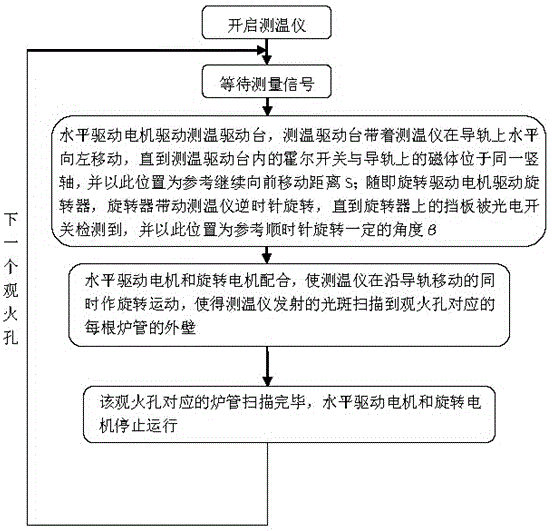

[0039] Such as figure 1 As shown, the two-phase driving synchronization method for the outer wall thermometer of the cracking furnace tube of this embodiment includes the following steps:

[0040] S1. Turn on the thermometer;

[0041] S2. Waiting for the measurement signal;

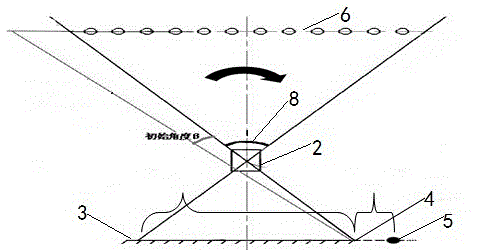

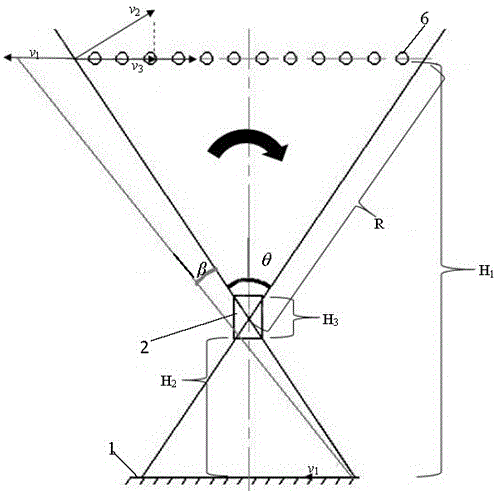

[0042] S3. The horizontal drive motor drives the temperature measurement drive platform, and the temperature measurement drive platform moves to the left on the rail with the thermometer until the first proximity switch in the temperature measurement drive platform and the first positioning part on the rail are on the same vertical axis , And use this position as a reference to continue moving forward for a distance S; then rotate the drive motor to drive the rotator, and the rotator drives the thermometer to rotate counterclockwise until the second positioning part on the rotator is detected by the second proximity switch, and Rotate a certain angle clockwise with this position as a reference β ;

[0043] S4. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com