Self-priming adapter of vehicle washing solution

A technology for converting joints and car washes, applied in the direction of pipes/pipe joints/pipes, siphons, lift valves, etc., can solve the problems of high cost, poor working environment, high cost, etc., to reduce operating costs, save energy, The effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

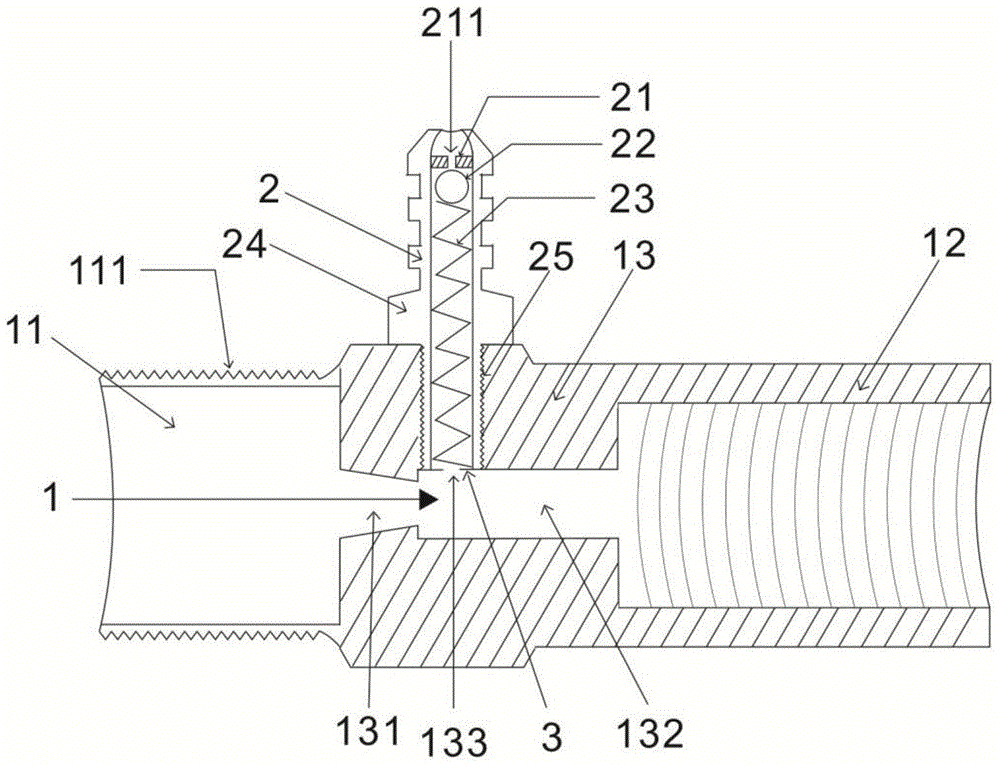

[0013] Refer to attached figure 1 , a self-priming conversion joint for car wash liquid, comprising a hollow joint body 1, the body is composed of a water inlet section 11 communicated with a water inlet pipe at one end, a liquid outlet section 12 communicated with a liquid spray pipe at the other end, and a middle The cavity section 13 is integrally formed, the aperture of the water inlet section and the liquid outlet section are larger than the aperture of the cavity section, and the flow path of the cavity section is composed of a circular platform hole 131 and a circular hole 132, and the starting end of the circular platform hole is connected to the water inlet. The sections are connected, the aperture at the beginning of the circular table hole is larger than the aperture at the end of the circular table hole, and the aperture at the end of the circular table hole is smaller than the aperture of the circular hole; the side of the cavity section is provided with a liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com