Dowel and setting method for fixing insulating materials

A technology of insulating materials and bolts, applied in the direction of pins, building components, connecting components, etc., can solve the problems of inventory and transportation in the logistics chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

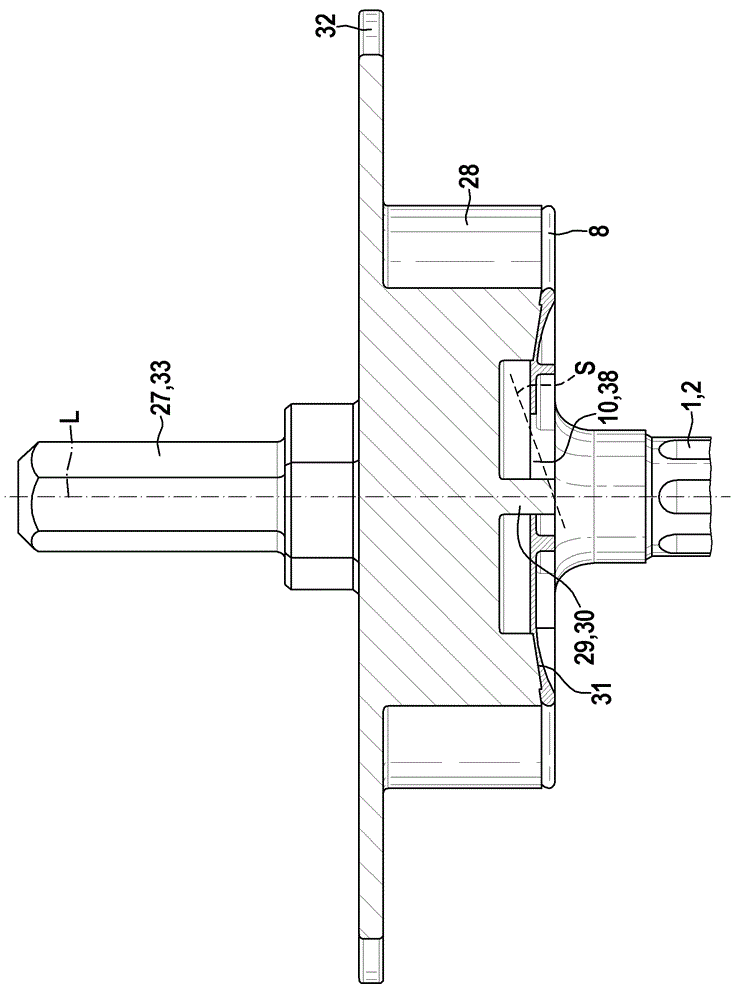

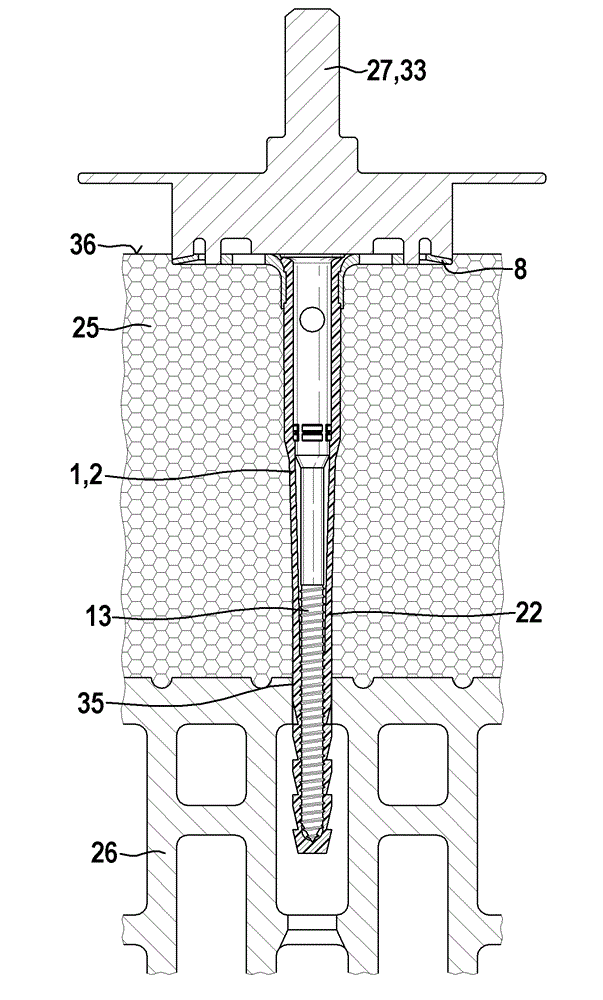

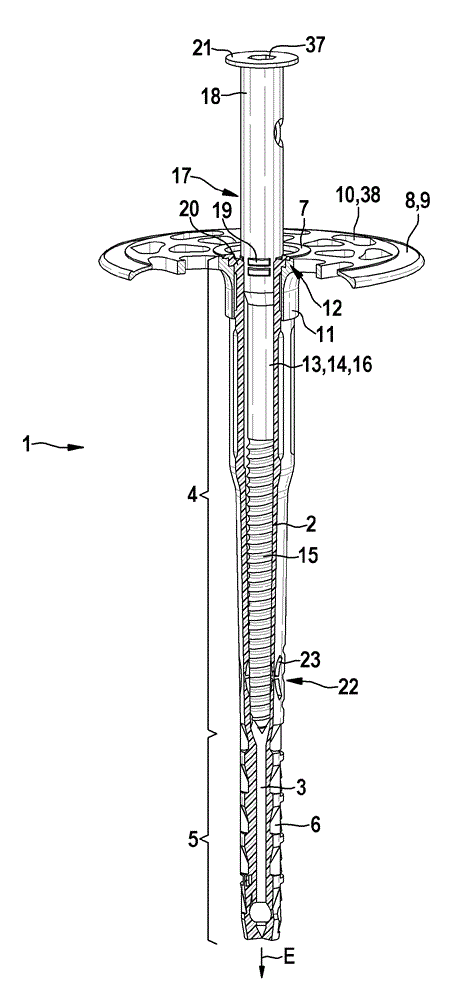

[0017] exist figure 1 The expansion bolt 1 shown in has an elongated expansion bolt sleeve 2 with a channel 3 extending along the longitudinal axis. The expansion bolt sleeve 2 has an expansion section 4 at the front end, to which a handle section 5 is connected. "Front end" and "rear end" always refer to the joining direction E of the expansion bolt during installation. The transition from the shank section 5 to the expansion section 4 is characterized in that the channel 3 narrows considerably to approximately half the diameter, while the outer diameter expands essentially only very slightly conically toward the rear. The shank section 4 is again expanded in the outer diameter by approximately 20% in the rear quarter. The expansion section 5 has such a notch 6 that the outer side of the expansion section 5 has a barb-shaped structure. At the rear end of the bolt sleeve 2 the shank section 4 is enlarged to the first flange 7 and a fastening disk 8 is arranged at this poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com