Concrete filled steel tube roadside support system used for large-section gob-side entry retaining and support method thereof

A technology of concrete filled steel tube and roadside support, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the damage and instability of roadside support structure, the decline of the bearing capacity of roadside filling walls, and the bending deformation of single hydraulic props. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

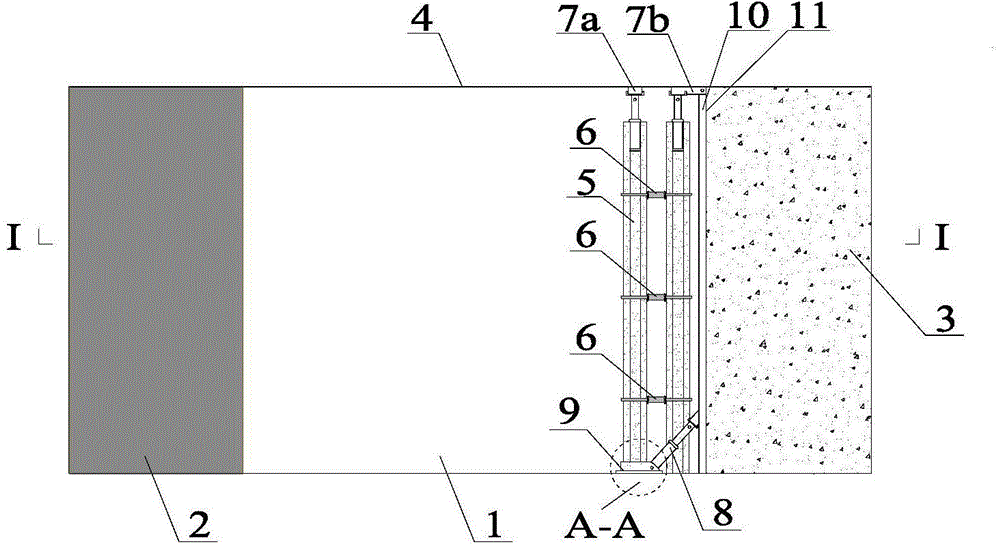

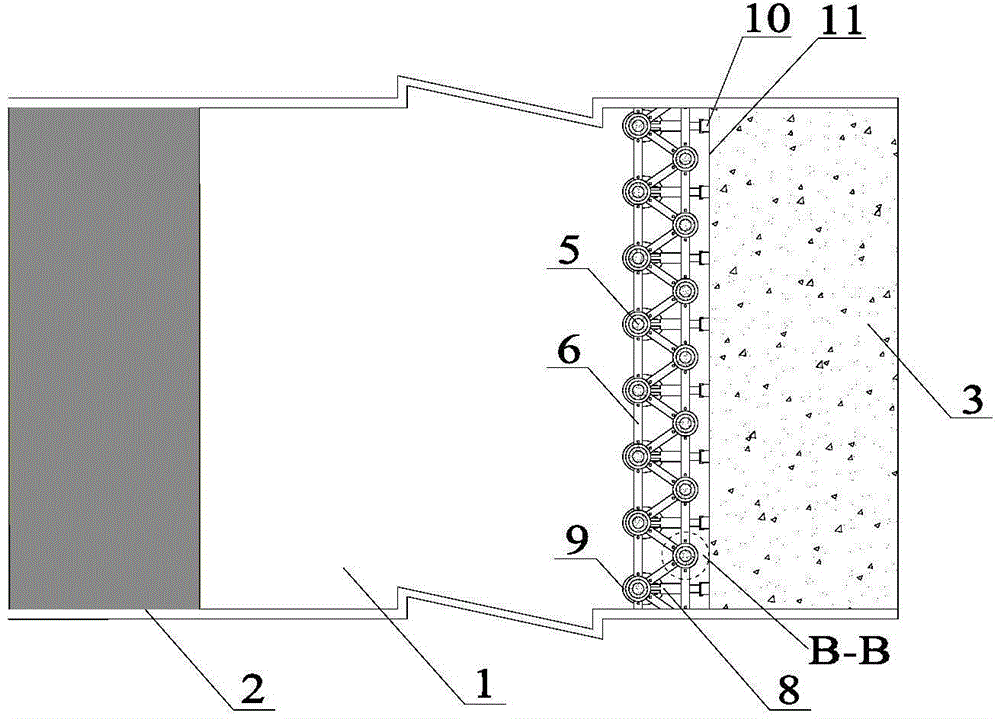

[0040] according to figure 1 - Figure 7 The concrete-filled steel pipe roadside support system of the present invention mainly includes Π-shaped steel beams 7a, 7b close to the top plate 4, the concrete-filled steel pipe column 5 supporting the Π-shaped steel beam on the top plate, the elliptical ring base 9 set on the lower part of the steel-filled steel tube concrete column 5, and The elliptical ring base 9 is an inclined hydraulic jack 8 of the articulated fulcrum, and the end of the inclined hydraulic jack 8 is supported on the vertical Π-shaped steel beam 10 and the metal mesh 11 filling the surface of the wall body 3 .

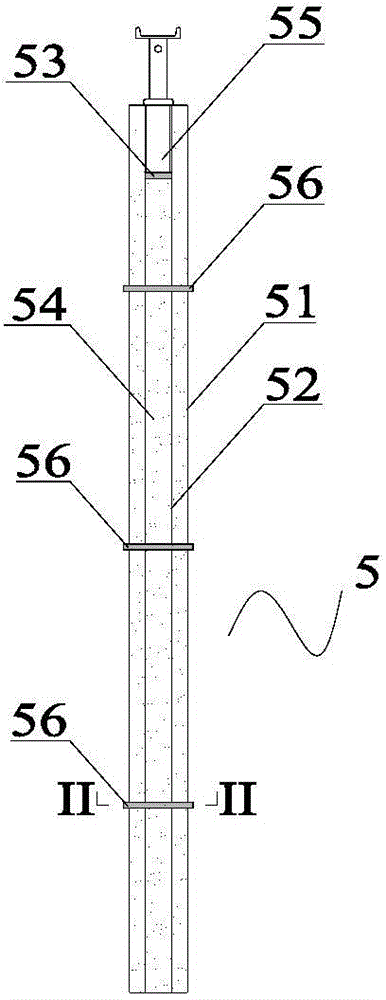

[0041] The concrete-filled steel pipe column 5 includes an 8-inch steel pipe 51, a 5-inch steel pipe 52, a rubber stopper 53, filled concrete 54, a vertical hydraulic jack 55, and a ring pipe clip 56.

[0042] Among them, the 8-inch steel pipe 51 and the 5-inch steel pipe 52 have the same length, the 5-inch steel pipe 52 is set in the 8-inch steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com