A kind of enhanced pulse pdc drill bit for drilling

A drill bit and pulse technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of pulse jet weakening, limited degree of cuttings tumbling and migration, repeated cutting, etc., to strengthen the pulse jet effect and shorten drilling. cycle, the effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

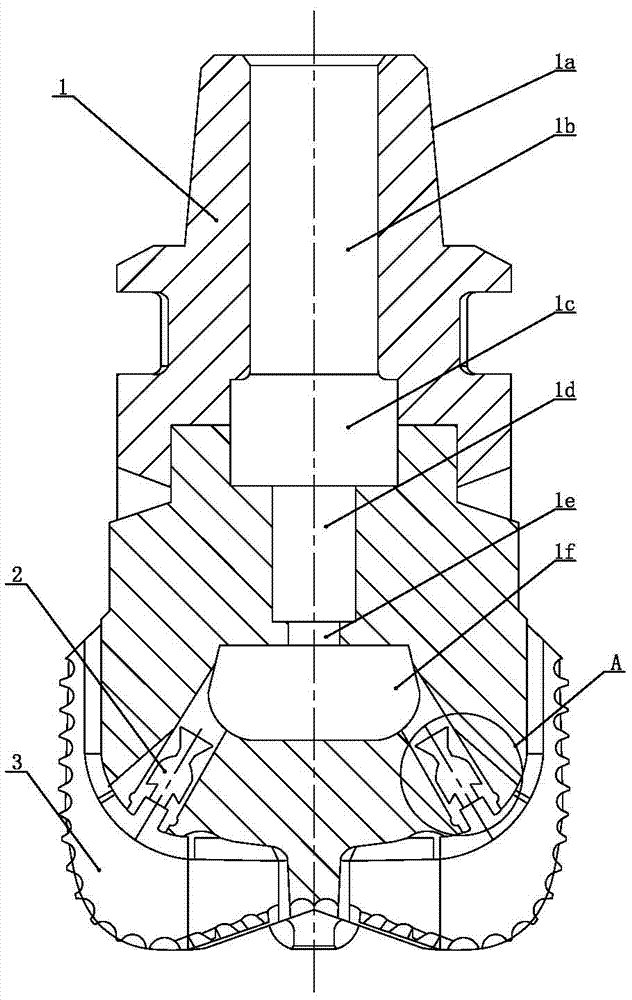

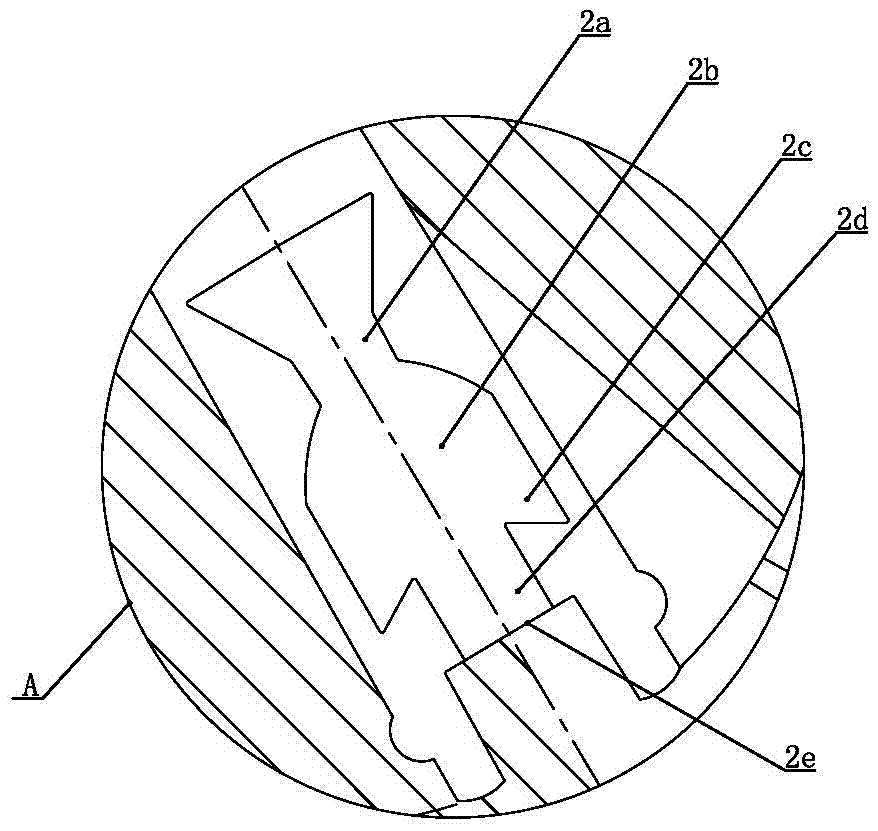

[0022] Such as figure 1As shown, the enhanced pulse PDC drill bit for drilling of the present invention comprises a drill body 1, the outer periphery of the upper end of the drill body 1 is provided with a drill pin 1a connected with a drill pipe, the lower end of the drill body 1 is equipped with a blade 3, the drill body 1 The inner cavity is provided with a water flow channel 1b along the axis, and the lower part of the water flow channel 1b is provided with a diversion area 1f coaxial with the water flow channel 1b, and spray holes are evenly distributed on the circumference of the lower part of the flow channel 1f, and nozzles are respectively installed in each spray hole. An organ pipe structure coaxial with the water flow channel is provided in the water flow channel 1b above the diversion area 1f, and the organ pipe structure is provided with an organ pipe water inlet chamber 1c, an organ pipe resonant chamber 1d and an organ pipe outlet 1e in sequence from top to botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com