Complete set of device for long helical drilling and reaming bottom and method for reaming

A long helical drilling and knife device technology, which is applied to drilling equipment and methods, rotary drilling, rotary drilling machines, etc., can solve the problems of poor rigidity of the expansion knife structure, difficulty in solving, and occupying space for soil transportation, etc., to achieve The effect of good reaming quality, high in-position rate and reliable pushing action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

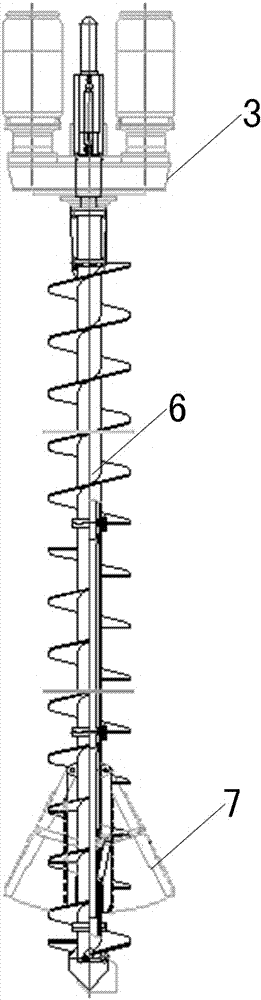

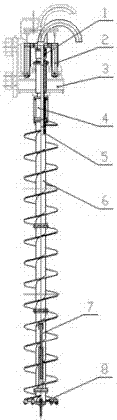

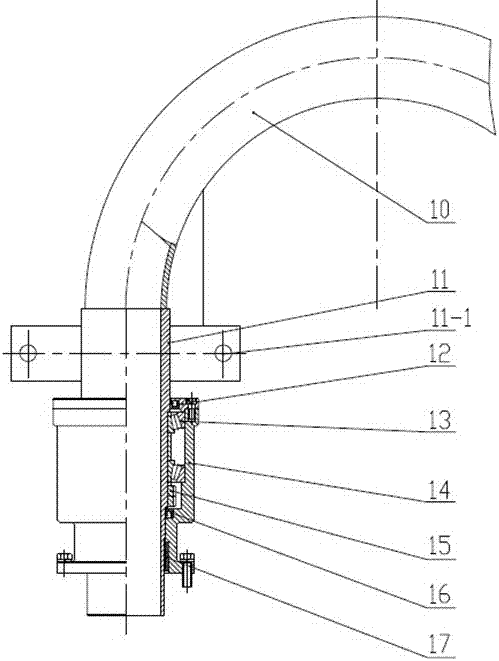

[0035] A complete set of device for long helical drilling bottom expansion, including concrete pouring rotary joint 1, cylinder driving bracket 2, power head 3, drill pipe transition joint 4, inner conduit 5, outer helical drill pipe 6, cutter expanding device 7, and drill bit 8 ,Hydraulic system. The concrete pouring rotary joint 1 includes an elbow 10, a core pipe 11, a bearing gland 12, a bearing 13, an outer body 14, a round nut 15, an oil seal 16, and a lining ring 17. The elbow 10 and the core pipe 11 are welded into a One body, the core tube and the outer body 14 are dynamically connected by the bearing gland 12, the bearing 13, the round nut 15 and the bushing, the oil seal 16 seals the bearing cavity, and the bushing 17 is used for the connection between the outer body 14 and the core tube 11 Rotary sealing, the two upper ear plates 11-1 of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com