Preparation method of W/O/W type multiple emulsion delaying chromium sol cross-linking system

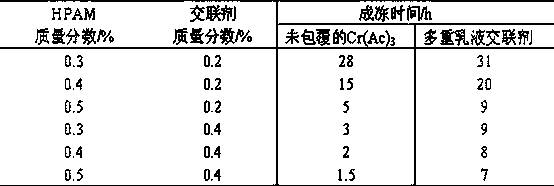

A multi-emulsion and cross-linking system technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of short freezing time of multi-emulsion cross-linking agents, and achieve increased viscosity, improved flow profile, and improved recovery. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (A) Add emulsifier Span-80 and residual oil to a certain amount of diesel oil, stir evenly, and serve as the oil phase for later use. The addition amount of emulsifier Span-80 is 2.8% of the total mass of the oil phase. Add residual oil The amount is 5% of the total mass of the oil phase;

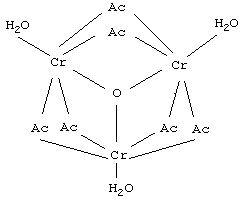

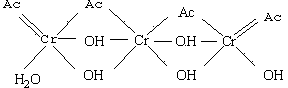

[0044] (B) Preparation of crosslinking agent with 8% mass fraction (according to CrCl 3 Calculate), accurately weigh CrCl with analytical balance 3 ·6H 2 O, CH 3 COONa·3H 2 O is fully dissolved in a small beaker with distilled water, and the resulting solution contains n(Cr 3+ ):n(Ac - )=1:3, and then add the obtained solution to a 100mL volumetric flask, dilute the volume, and shake well. When the aging time is more than 3 days, the mother liquor of cross-linking agent chromium sol is dark green or slightly purple transparent liquid. Prepare a solution with a volume fraction of 2% as the internal water phase for later use.

[0045] (C) Mix the prepared oil phase and water phase in a vo...

Embodiment 2

[0052] (A) Add emulsifier Span-80 and residual oil to a certain amount of diesel oil, stir evenly, and serve as the oil phase for later use. The addition amount of emulsifier Span-80 is 2.8% of the total mass of the oil phase. Add residual oil The amount is 5% of the total mass of the oil phase;

[0053] (B) Preparation of crosslinking agent with 8% mass fraction (according to CrCl 3 Calculate), accurately weigh CrCl with analytical balance 3 ·6H 2 O, CH 3 COONa·3H 2 O is fully dissolved in a small beaker with distilled water, and the resulting solution contains n(Cr 3+ ):n(Ac - )=1:3, and then add the obtained solution to a 100mL volumetric flask, dilute the volume, and shake well. When the aging time is more than 3 days, the mother liquor of cross-linking agent chromium sol is dark green or slightly purple transparent liquid. Prepare a solution with a volume fraction of 2% as the internal water phase for later use.

[0054] (C) Mix the prepared oil phase and water phase in a vo...

Embodiment 3

[0061] (A) Add emulsifier Span-80 and residual oil to a certain amount of diesel oil, stir evenly, and serve as the oil phase for later use. The addition amount of emulsifier Span-80 is 2.8% of the total mass of the oil phase. Add residual oil The amount is 5% of the total mass of the oil phase;

[0062] (B) Prepare a crosslinking agent with a mass fraction of 8% based on CrCl3, and accurately weigh CrCl with an analytical balance 3 ·6H 2 O, CH 3 COONa·3H 2 O is fully dissolved in a small beaker with distilled water, and the resulting solution contains n(Cr 3+ ):n(Ac - )=1:3, then add the obtained solution to a 100mL volumetric flask, constant volume, fully shake, aging time more than 3d, the mother liquor of crosslinking agent chromium sol is dark green or slightly purple transparent liquid, and the volume fraction is 2% The solution is used as the internal water phase;

[0063] (C) Mix the prepared oil phase and water phase at a volume ratio of 3:7, use FA25 high-shear dispersin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com