Ultraviolet curable adhesive composition for optics, the cured layer and optical member

A UV-curable technology, used in adhesives, optics, nonlinear optics, etc., to achieve the effects of no peeling, excellent durability, and excellent visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

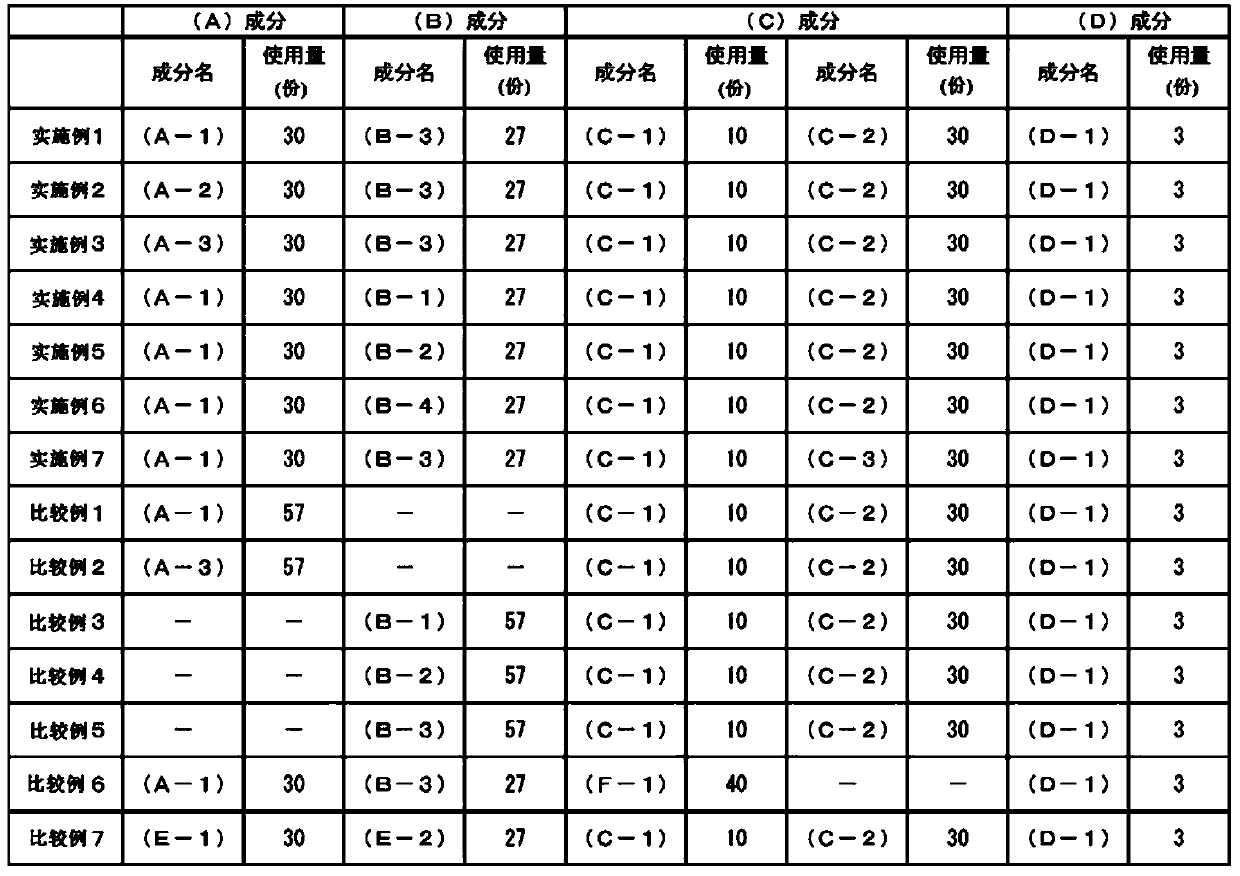

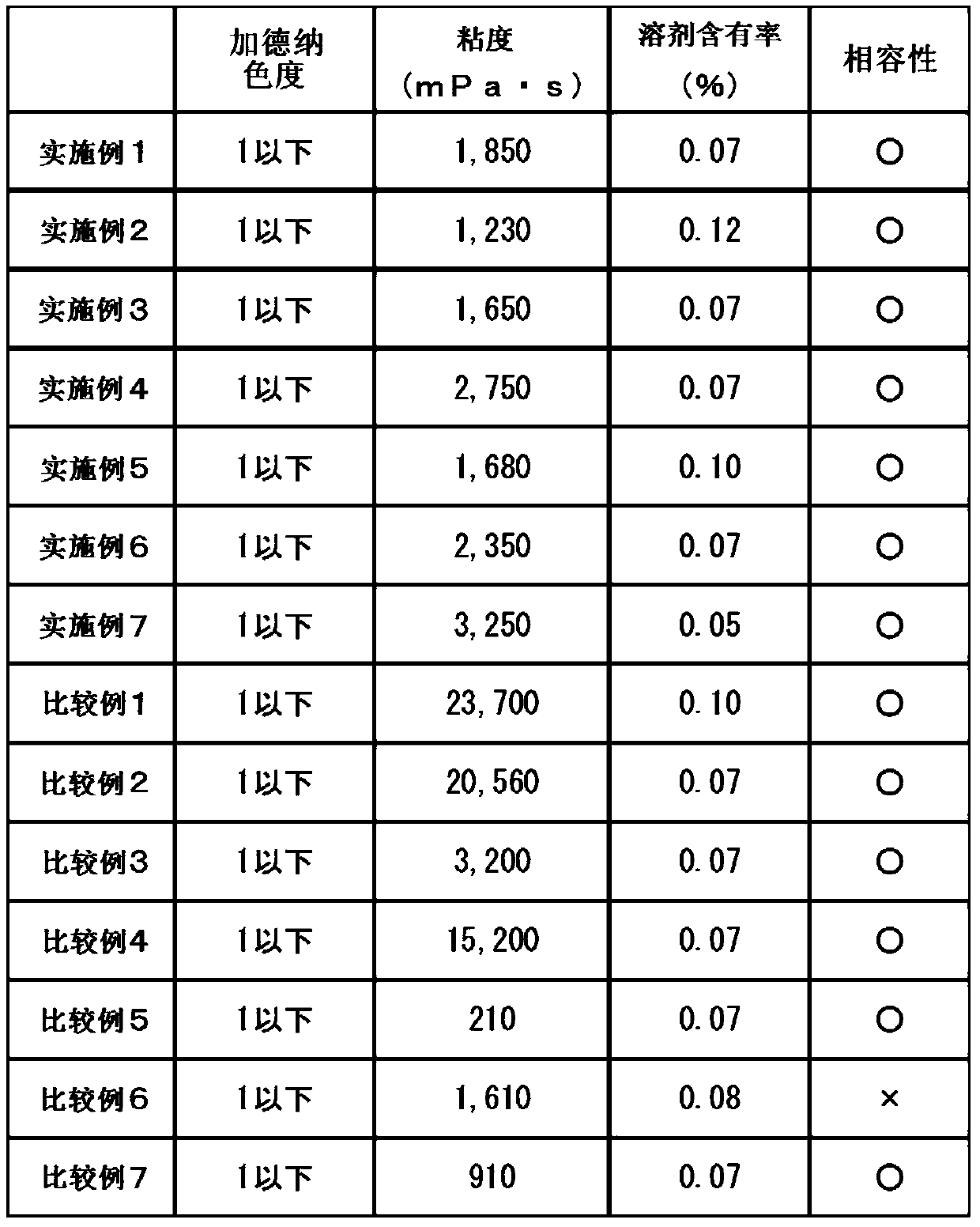

Examples

Embodiment

[0054] Hereinafter, the present invention will be described more specifically by way of examples. However, the present invention is not limited to these Examples. In addition, in an Example, unless otherwise indicated, "%" and "part" mean "weight%".

[0055]

Synthetic example 1

[0057] (A-1) Synthesis of Components

[0058] In the reaction device with condensing tube and agitator, add 910 parts of hydrogenated polybutadiene polyols (manufactured by Nippon Soda Co., Ltd., trade name "NISSO-PB GI-3000") with a weight average molecular weight of 4000, Isofor 81 parts of ketone diisocyanate and 0.2 parts of tin octoate were heated up to 80° C. and kept for 2 hours. Then, the completion of the reaction was confirmed by NCO measurement, and a hydroxyl-terminated urethane oligomer was obtained as an intermediate. Then, 19 parts of 2-isocyanatoethyl methacrylate were added and kept at 80° C. for 2 hours. Then, the completion of the reaction was confirmed by NCO measurement, thereby obtaining a polyurethane with a weight average molecular weight of 36,000 and an average number of functional groups of 2.0. acrylate oligomer (hereinafter referred to as (A-1) component). In addition, this weight average molecular weight is the polystyrene equivalent value obtain...

Synthetic example 2

[0060] (A-2) Synthesis of Components

[0061] In the same reaction device as in Synthesis Example 1, add 925 parts of hydrogenated polybutadiene polyols, 51 parts of isophorone diisocyanate and 0.2 parts of tin octoate used in Synthesis Example 1, heat up to 80 °C and After retaining the temperature for 2 hours, the completion of the reaction was confirmed by NCO measurement, and a hydroxyl-terminated urethane oligomer was obtained as an intermediate. Then, 24 parts of 2-isocyanatoethyl methacrylate was added, and the temperature was kept at 80°C for 2 hours, and the completion of the reaction was confirmed by NCO measurement, thereby obtaining a polyurethane methacrylic acid having a weight average molecular weight of 21,000 and an average functional group number of 2.0. Ester oligomer (hereinafter referred to as (A-2) component).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com