Heat ray-shielding material

A heat ray shielding, metal particle technology, applied in thin material processing, optics, instruments, etc., can solve the problems of increasing visible light transmittance, low radio wave transmittance, low visible light transmittance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] -Synthesis of metal flat particles-

[0124] A 150 mM hydrazine aqueous solution (0.75 mL) was continuously added to the solution containing the following components, and stirred at 1,000 rpm at 25° C. for 2 hours to obtain a cloudy blue particle dispersion.

[0125] ●Ion-exchanged water………762g

[0126] Silver nitrate (manufactured by Wako Junyaku Co., Ltd.) ... 12.7 mg

[0127] Sodium citrate trihydrate (manufactured by Wako Junyaku Co., Ltd.) 100.6 mg

[0128] EDTA4 sodium acetate (manufactured by Wako Junyaku Co., Ltd.) ... 5.0 mg

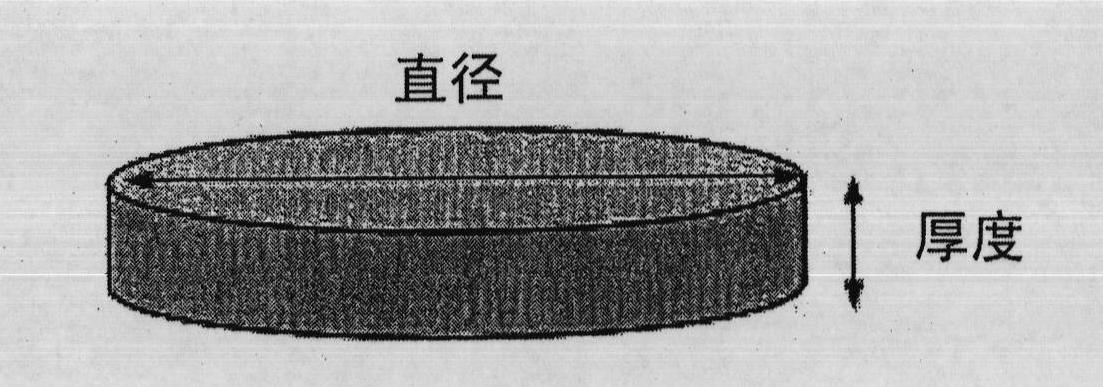

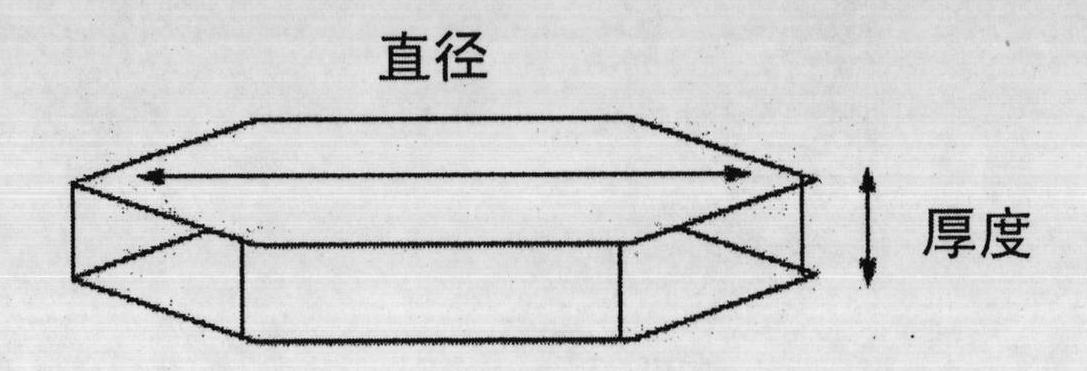

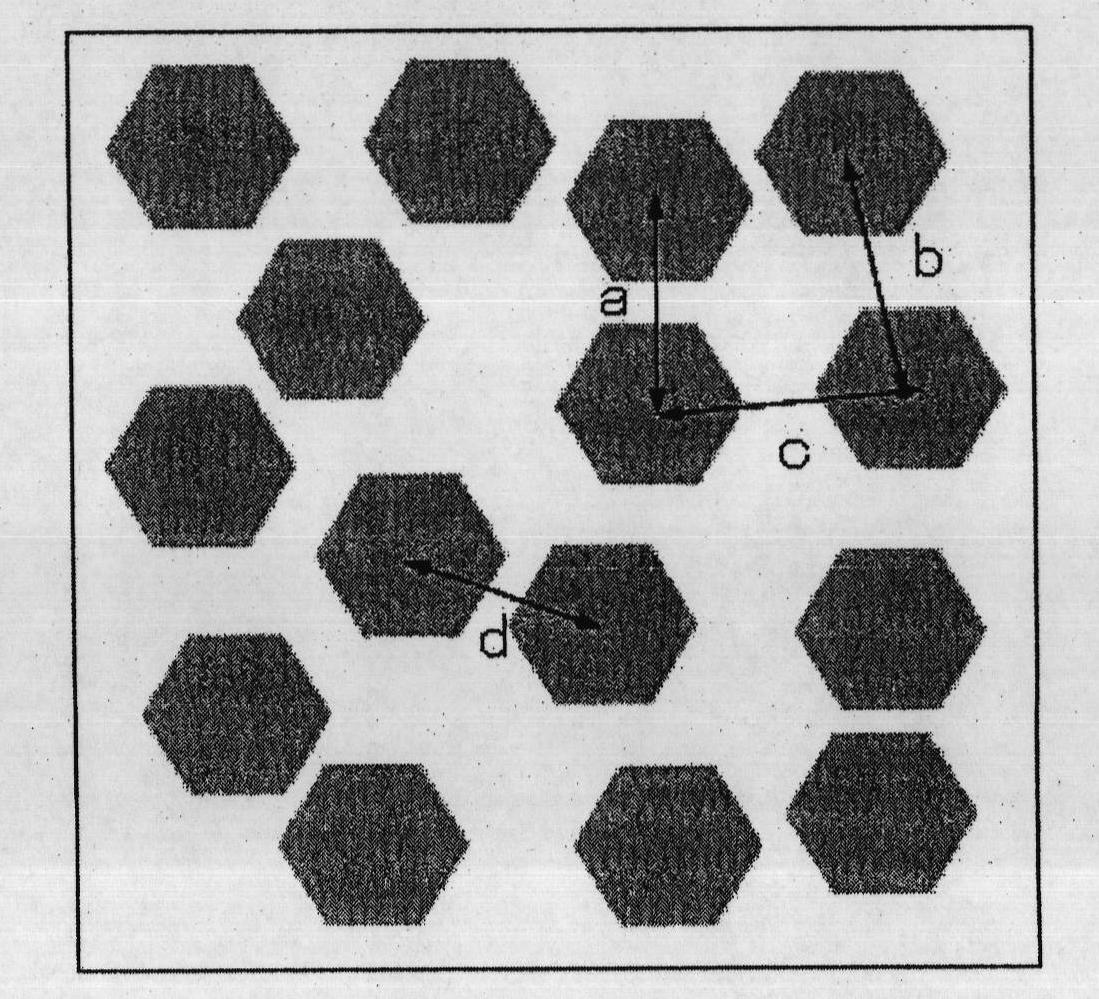

[0129] It was confirmed that hexagonal flat particles made of silver (hereinafter, referred to as "hexagonal flat particles") having an average particle diameter (average circle-equivalent diameter) of 40 nm were formed in the particle dispersion. In addition, the thickness of the hexagonal flat particles was measured by an atomic force microscope (NANOCUTE II, manufactured by SEIKO INSTRUMENTS INC.). As a result, it was found that th...

Embodiment 2 to 24 and comparative example 4

[0171] Metal flat particles of Examples 2 to 24 and Comparative Example 4 were prepared in the same manner as in Example 1, except that the conditions for producing flat metal particles were changed to those shown in Tables 1-A and 1-B And the heat ray shielding materials of Examples 2 to 24 and Comparative Example 4.

[0172] Notice, Figure 5A Shown is an SEM image of the heat ray shielding material obtained in Example 23, and the image was observed at a magnification of 10,000 times; Figure 5B Shown is an SEM image of the heat ray shielding material obtained in Example 23, and the image was observed at a magnification of 50,000 times.

Embodiment 25

[0174] Except after synthesizing the Ag flat particles as shown in Table 1-B, when preparing the substrate for the heat ray reflective material, the Ag flat particle dispersion was distributed on the surface of the substrate by dropping, and then heated in an oven at 100°C Drying was performed for 30 minutes, but a heat ray shielding material was prepared in the same manner as in Example 5, except that the substrate was dipped in the Ag flat particle dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com