C30 grade steel-doped slag recycled aggregate self compacting concrete and preparation method thereof

A technology of self-compacting concrete and recycled aggregate, applied in the field of building materials, can solve the problem of labor shortage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

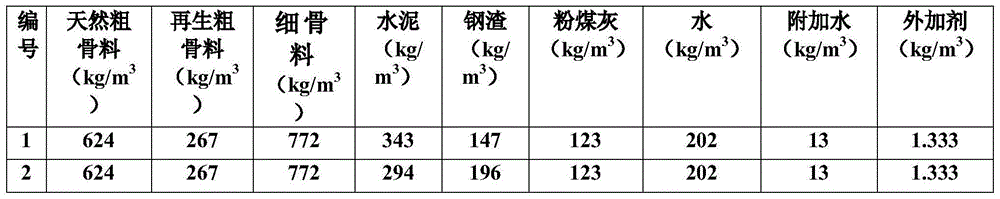

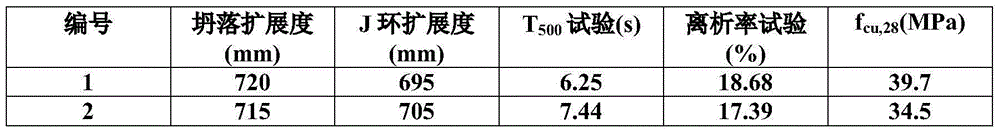

Embodiment

[0071] (1) Prepare raw materials

[0072] Cement: P O42.5 ordinary portland cement, apparent density is 3.20g / cm 3 .

[0073] Fly ash: Class I fly ash, the apparent density is 2.42g / cm 3 .

[0074] Fine aggregate: medium-sized quartz sand with a fineness modulus of 2.4 and a bulk density of 1.54g / cm 3 , the apparent density is 2.64g / cm 3 , the moisture content is 0.35%.

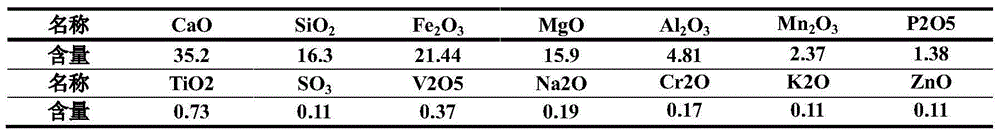

[0075] Steel slag: the steelmaking waste slag that has been placed in the steel mill for more than 6 months has been iron-removed, ball milled and screened, and the steel slag powder with a particle size of less than 0.08mm is selected, and the apparent density is 2.36g / cm 3 , the basicity coefficient of steel slag is 1.99, and the steel slag powder complies with the GB / T 20491-2006 standard "Steel slag powder used in cement and concrete".

[0076] Natural coarse aggregate: 5-20mm continuous graded crushed stone, with an apparent density of 2.87g / cm 3 , bulk density is 1.53g / cm 3 , The water absorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com