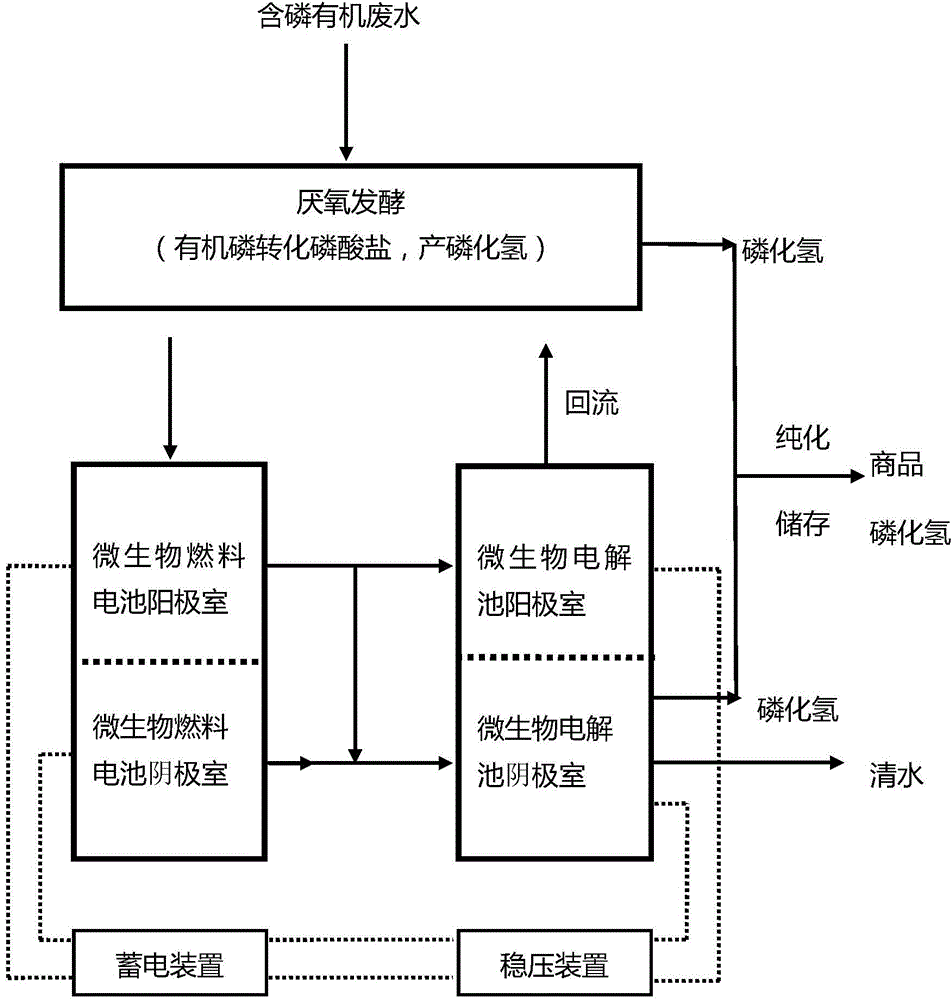

Multi-stage phosphor removing and hydrogen phosphide production method of phosphor-containing organic wastewater

A technology for organic wastewater and phosphine, applied in phosphine, chemical instruments and methods, anaerobic digestion treatment, etc., can solve the problem of low phosphine yield, difficult to continue research, and difficult to quantitatively determine the conversion of total phosphorus in water For problems such as phosphine efficiency, to achieve the effect of improving economic value and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] A method for producing phosphine by multi-stage phosphorus removal from organic wastewater:

[0043] (1) Anaerobic microbial phosphorus removal to produce phosphine

[0044] Inoculate the sludge of phosphine-producing bacteria in the anaerobic sequencing batch reactor, adjust the pH of phosphorus-containing organic wastewater to 6-7, add it to the anaerobic sequencing batch reactor, and control the hydraulic retention time in the reactor 20h, by anaerobic treatment, the organic phosphorus in the waste water is preliminarily degraded into phosphate and part of the phosphorus in the waste water is transformed into phosphine, and the phosphine is collected; the concentration of the sludge of the phosphine-producing bacteria in the reactor 4g / L;

[0045] Influent COD is 4000mg / L, TP is 5mg / L. Organic phosphorus is converted into inorganic phosphorus under the action of phosphine-producing bacteria, which increases the concentration of inorganic phosphorus in the effluent;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com