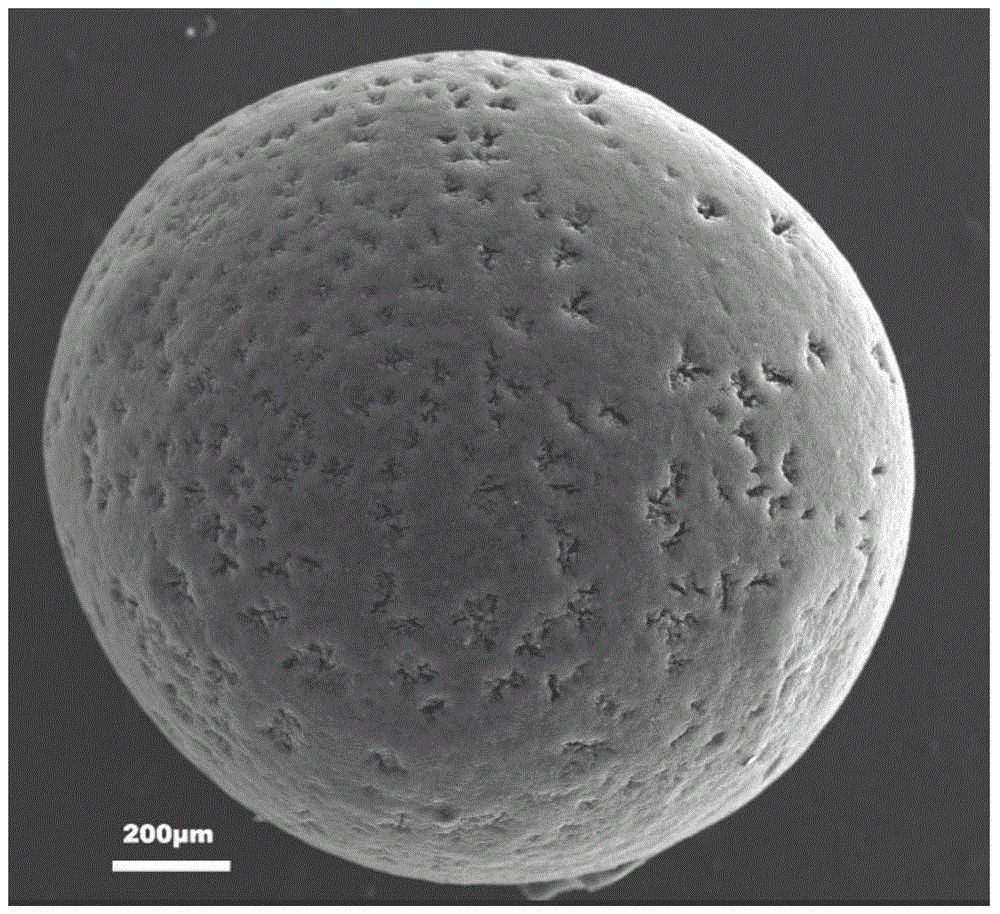

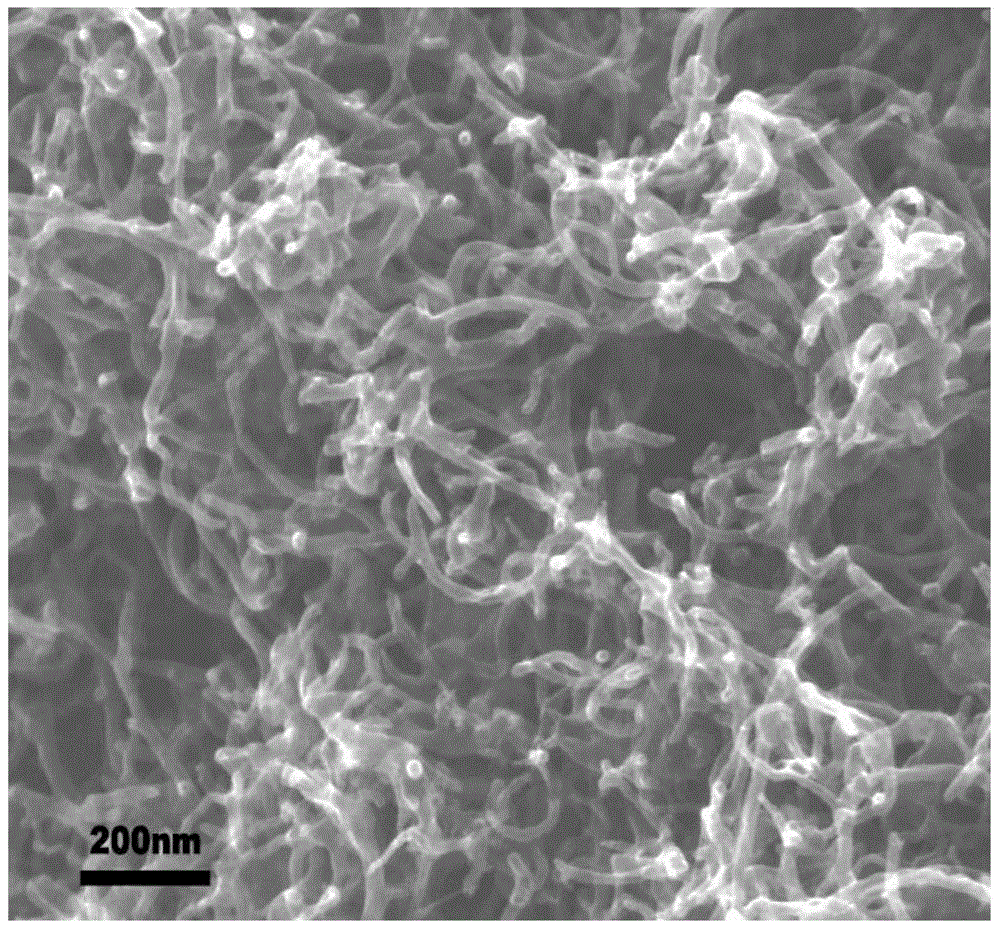

A preparing method of a porous carbon nanotube-charcoal spherical composite material

A technology of composite materials and carbon nanotubes, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low production efficiency and difficult activation, and achieve large mesopore volume and pore size. The structure is developed and the effect of maintaining sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Weigh 1 g of self-made carbon nanotubes and place them in 30 mL of ethanol aqueous solution (volume concentration of ethanol is 60%) for ultrasonic dispersion for 60 min;

[0045] (2) Take by weighing 2g of liquid phenolic resin and dissolve it in 20mL of ethanol to obtain a resin dilution, wherein the mass concentration of the liquid phenolic resin is 11.2%; add the carbon nanotubes after ultrasonic dispersion to the resin dilution, and ultrasonically stir for 30min to obtain The homogeneous suspension of carbon nanotubes is then fully stirred after adding 0.3g p-toluenesulfonyl chloride to obtain a spherical liquid;

[0046] (3) The measured density is 0.95g / cm 3 500mL of silicone oil is placed at the bottom of the container, and the measured density is 0.83g / cm 3 Place 500mL of liquid paraffin oil on top of the silicone oil to form a two-layer oil bath, and preheat it to 70°C in an oven; select a No. Drop the sphere-forming solution into two layers of oil baths...

Embodiment 2

[0052] (1) Weigh 1 g of self-made carbon nanotubes and place them in 30 mL of ethanol aqueous solution (volume concentration of ethanol is 60%) for ultrasonic dispersion for 60 min;

[0053] (2) Take by weighing 6g of liquid phenolic resin and dissolve it in 20mL of ethanol to obtain a resin dilution, wherein the mass concentration of the liquid phenolic resin is 27.5%; add the carbon nanotubes after ultrasonic dispersion to the resin dilution, and ultrasonically stir for 60min to obtain The homogeneous suspension of carbon nanotubes is then fully stirred after adding 0.6g p-toluenesulfonyl chloride to obtain a spherical liquid;

[0054] (3) The measured density is 0.95g / cm 3 500mL of silicone oil is placed at the bottom of the container, and the measured density is 0.83g / cm 3 Place 300mL of liquid paraffin oil on top of the silicone oil to form a two-layer oil bath, and preheat it to 65°C in an oven; select a No. Drop the sphere-forming liquid into two layers of oil baths t...

Embodiment 3

[0060] (1) Weigh 2 g of self-made carbon nanotubes and place them in 40 mL of ethanol aqueous solution (volume concentration of ethanol is 60%) for ultrasonic dispersion for 120 min;

[0061] (2) Take by weighing 1.5g liquid phenolic resin and be dissolved in 20mL ethanol to obtain resin dilution, wherein the mass concentration of liquid phenolic resin is 8.7%; Add the carbon nanotubes after ultrasonic dispersion in the resin dilution, ultrasonically stir for 90min, To obtain a uniform suspension of carbon nanotubes, then add 0.24g of p-toluenesulfonyl chloride and then fully stir to obtain a spherical solution;

[0062] (3) The measured density is 0.95g / cm 3 300mL of silicone oil is placed at the bottom of the container, and the measured density is 0.91g / cm 3 300mL of soybean oil is placed on top of the silicone oil, and the density is 0.83g / cm 3 Place 500mL of liquid paraffin oil on top of the silicone oil to form a three-layer oil bath, and preheat it to 70°C in an oven; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com