Chain cycle load device

A chain circulation and loading technology, which is applied in the direction of transportation, packaging, conveyors, etc., can solve problems such as chain failure, chain breakage, and insufficient dynamic load, and achieve the effects of reducing chain elongation, prolonging service life, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

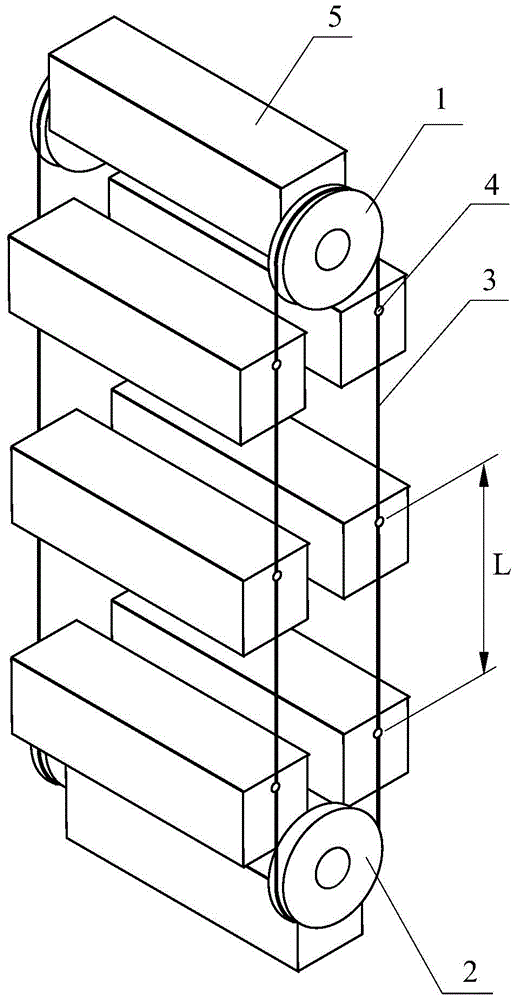

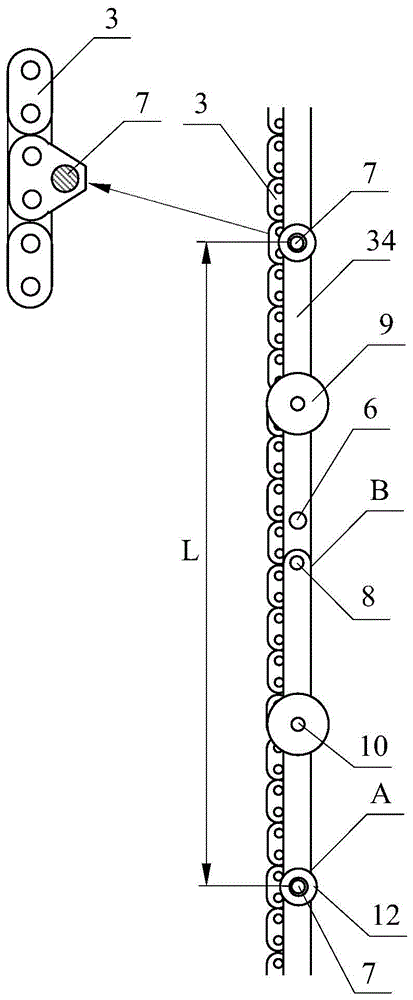

[0052] In order to solve the defect in the prior art that the chain is elongated due to long-term use, the invention discloses a chain circulation carrying device, such as figure 2 As shown, it includes two rows of endless chains 3 running in parallel and in the same direction. The two rows of endless chains 3 are installed on the sprocket set. When the endless chain 3 is a horizontal loop, the sprocket set includes left and right sprockets, and When the endless chain 3 circulates up and down, it includes the upper sprocket 1 and the lower sprocket 2, and a plurality of warehouses 5 are suspended at the same hanging distance between the two rows of endless chains 3. The hanging distance described here refers to the The number of links of the circular chain 3 between the warehouses 5, in figure 1 with figure 2 Indicated by L, the loading device also includes two closed rod chain rings corresponding to the two endless chains 3 one by one, the rod chain rings include several c...

Embodiment 2

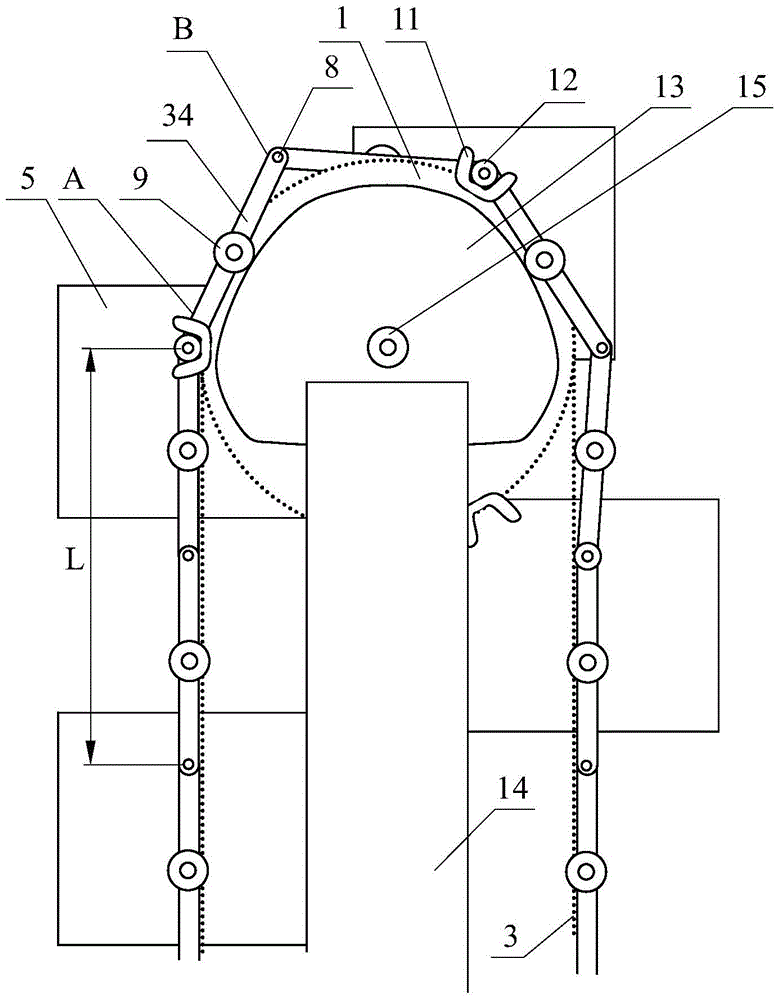

[0054] Such as image 3 As shown, this embodiment is further improved on the basis of embodiment 1, and the two functions of transmitting motion and bearing are separated, and the circulating chain 3 only transmits motion, while the rod link is used for bearing. In the present embodiment, the sprocket set includes an upper sprocket 1 and a lower sprocket 2 which are rotatably mounted on the frame 14, and the endless chain 3 is installed to circulate vertically between the upper sprocket 1 and the lower sprocket 2, The frame 14 is provided with a rod chain driving mechanism for driving the circular motion of the rod chain ring. The frame 14 is provided with an upper load-bearing guide rail 13 within the closed range of the rod chain ring. The upper load-bearing guide rail 13 includes an upper load-bearing convex surface. This upper load-bearing convex surface cooperates with the middle part of the connecting rod 34 to support the middle part of the connecting rod 34 all the tim...

Embodiment 3

[0059] As a cycle loading device, it is necessary to hang the warehouse 5 as densely as possible, and this embodiment is further realized on the basis of embodiment 2.

[0060] Specifically, such as Figure 5 As shown, several suspensions for hanging the warehouse 5 are arranged on the rod chain ring, and the suspension includes a hinge rod 36 and two support rods 35, and one end of the hinge rod 36 is hinged on the rod chain ring , the other end of the hinge pole 36 is provided with a hanging hole 6, the suspension shaft 4 of the warehouse 5 is installed in the hanging hole 6, and one end of the two poles 35 is hinged to each other through the sliding hinge shaft 25, and the two poles 35 The other end is respectively hinged on the rod chain ring, and the sliding hinge shaft 25 is slidably arranged on the hinge rod 36 along the length direction of the hinge rod 36, and its specific sliding structure is as follows: Figure 5 As shown, the hinge rod 36 is provided with a strip-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com