A separating and cleaning device for residual plastic films

A technology for cleaning device and residual film, which is applied to cleaning methods and utensils, cleaning methods using liquids, and recycling technologies, etc., can solve problems such as difficulty in rooting the root system, reduced nutrient capacity, and crop yield reduction, thereby reducing labor waste. , Reasonable structure layout, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

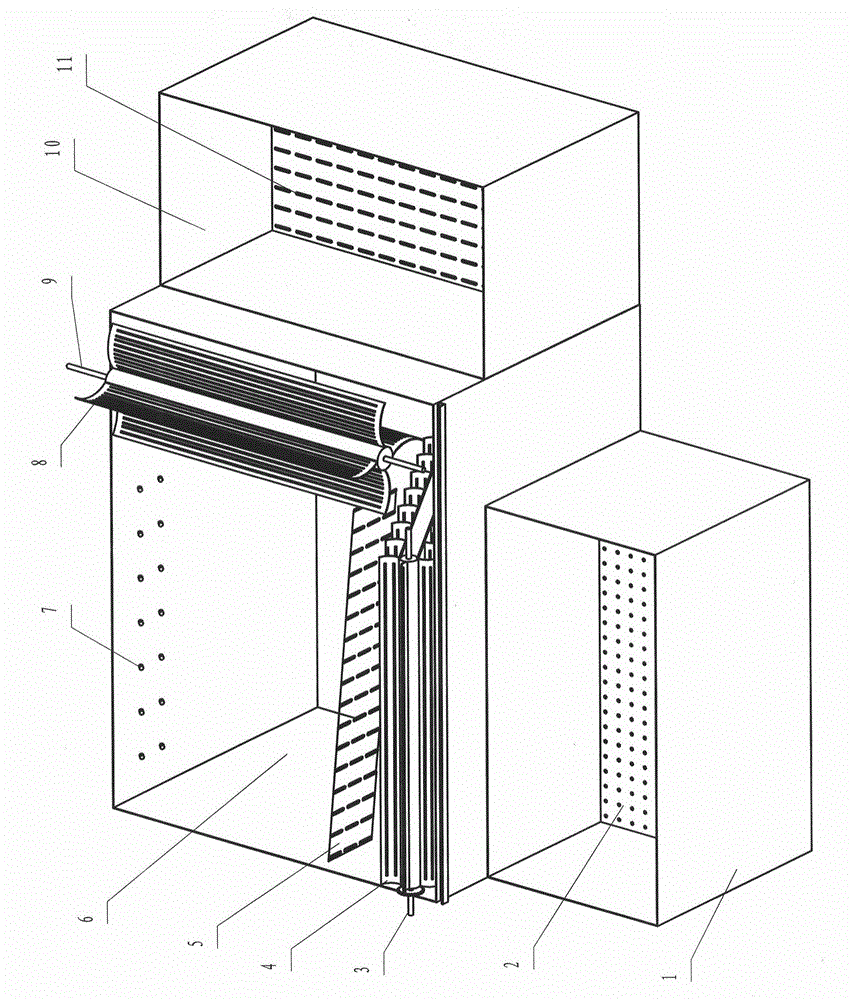

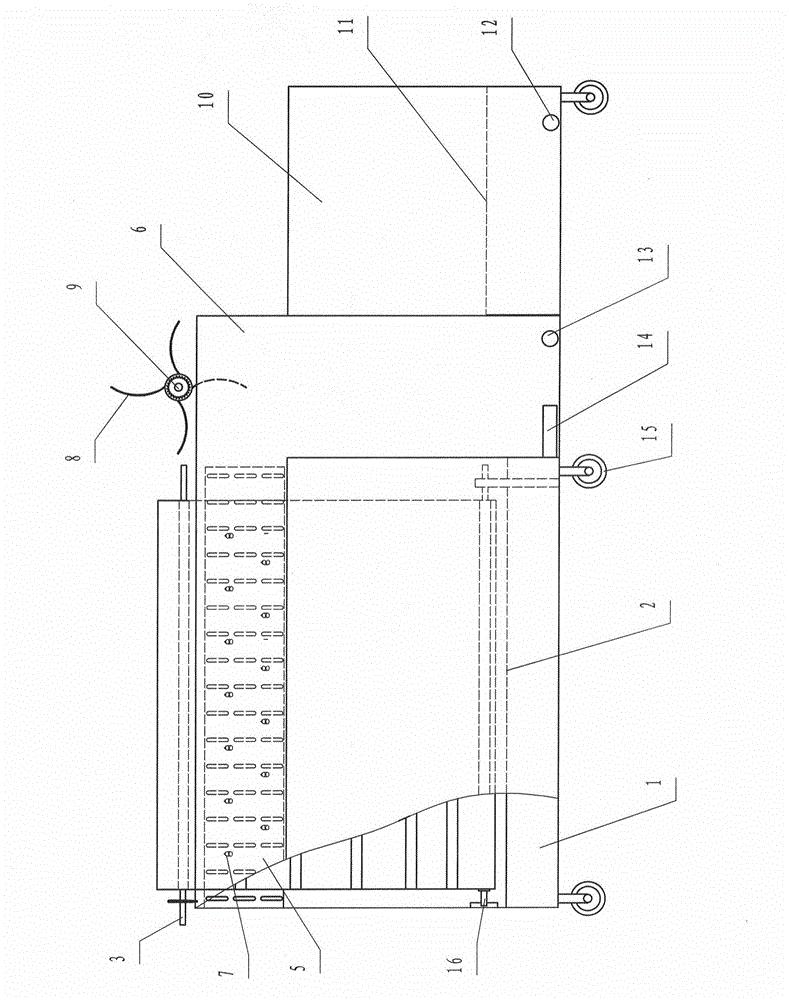

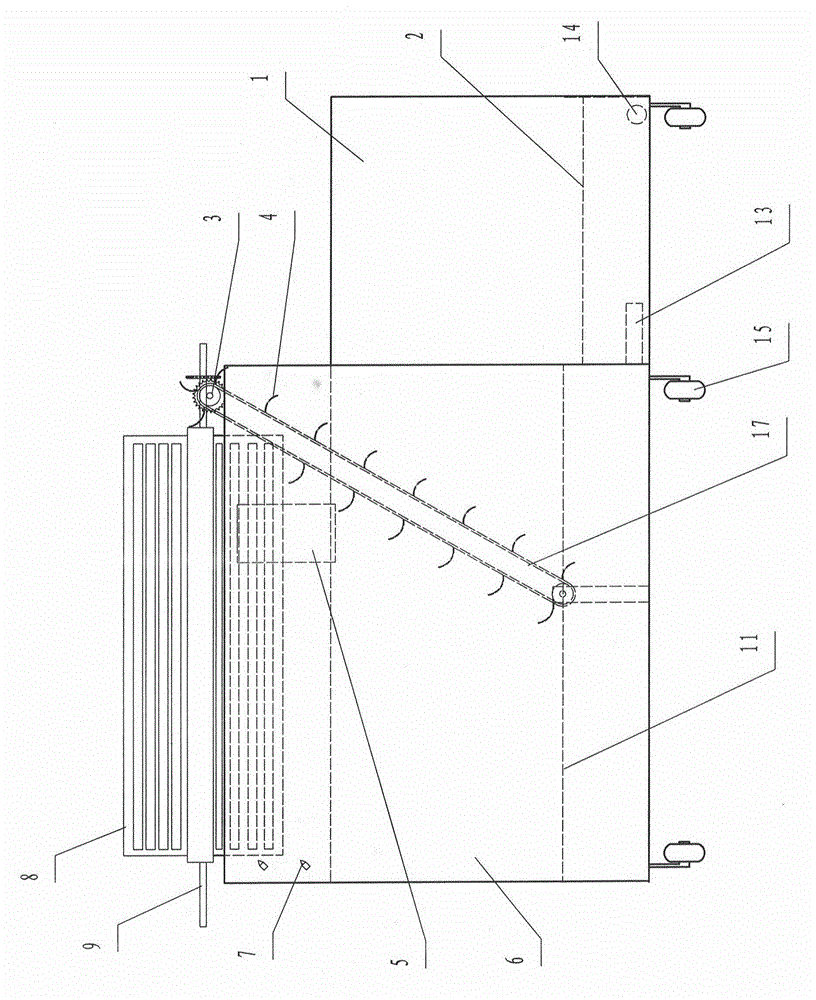

[0021] Embodiment: refer to attached Figure 1-8 , this embodiment consists of a cleaning device, a film collecting device, and a rod collecting device;

[0022] The cleaning device is composed of a cleaning box 6, a partition plate 5, a spray head 7, and a water outlet valve 13. The partition plate 5 is set at an oblique angle to the wall of the box plate in the cleaning box 6 to prevent straw from entering Membrane collection device, the partition plate 5 is provided with a partition screen hole 20, and the spray head 7 and the wall of the cleaning box are arranged in an inclined shape. Move to the direction of the rod collecting device, and the water outlet valve 13 is located at the bottom of the cleaning box 6;

[0023] The film collection device is composed of a film collection box 1, a film collection box sieve plate 2, a conveyor belt 17, a conveyor belt driving shaft 3, a conveyor belt driven shaft 16 and a film collection box outlet 14. The film collection box 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com