Tail cone molding die and molding method thereof

A molding die and tail cone technology, which is applied in the field of aero-engines, can solve problems such as irregular shapes of blanks, extruded superimposed parts, and skewed tops of blanks, etc., to achieve the effects of reducing waste, increasing yield, and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0034] Unless otherwise specified, the technical means used in the embodiments are conventional means well known to those skilled in the art. The mold provided by the invention is not limited to tail cone molding for aero-engines, and can also be used in other conical surface molding parts. However, it is preferably used in aero-engines. At this time, the molding efficiency is high, and parts with conical surfaces, excessively arcuate surfaces and cylindrical surfaces can be obtained at one time.

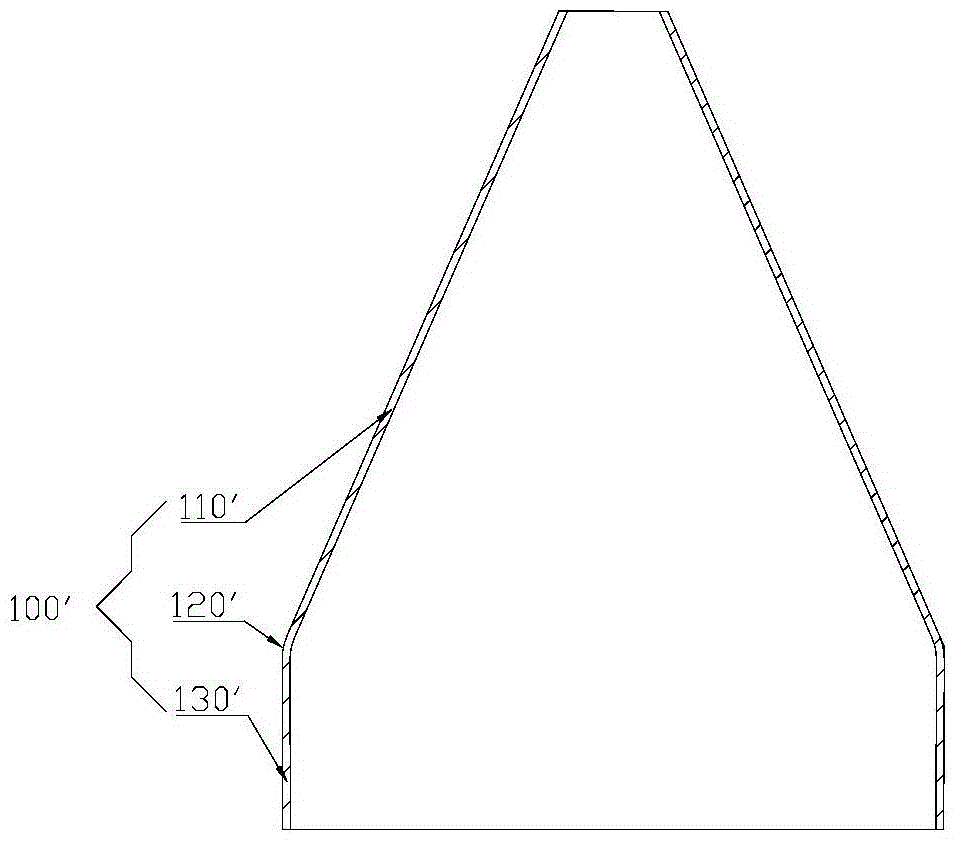

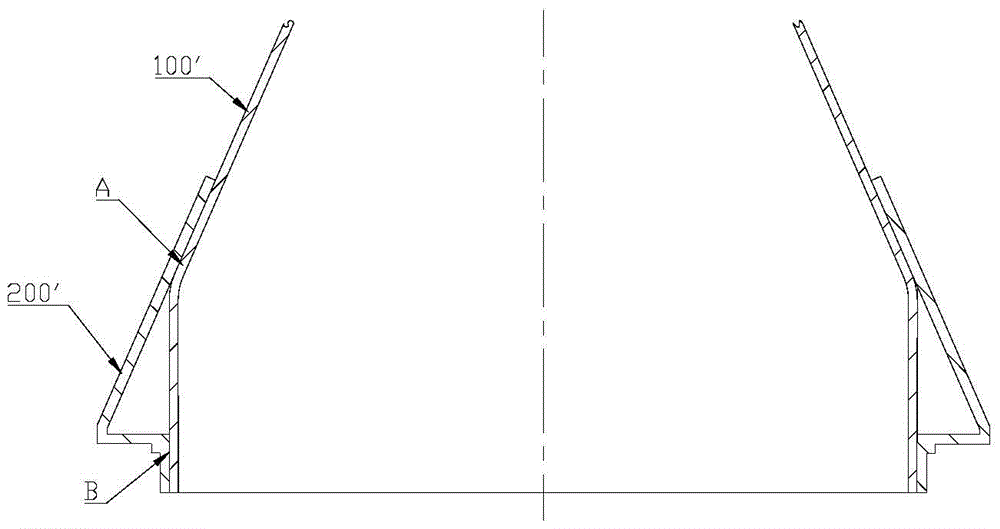

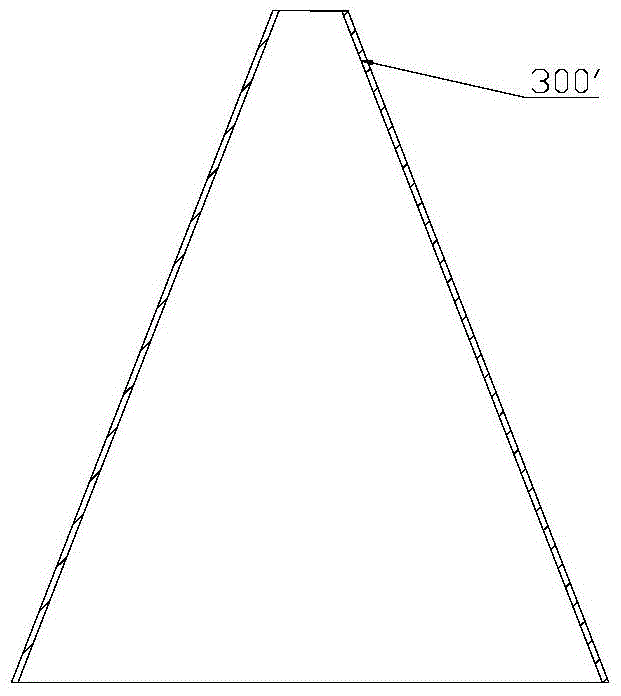

[0035] see Image 6, the tail cone forming mold provided by the present invention includes a lower template 100, an upper template 900, a die 600 and a punch 500 whose centerlines are overlapped, a forming groove 630 is arranged at the center of the die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com