A kind of impurity sorting comprehensive crusher for fluidized bed boiler fuel

A fluidized bed boiler and crusher technology, which is applied to fluidized bed combustion equipment, fuels burned in a molten state, combustion methods, etc., can solve the problems of polluting the environment, poor commodity quality, and many impurities, and achieves reduction of harmful waste gas, The effect of reducing environmental pollution and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

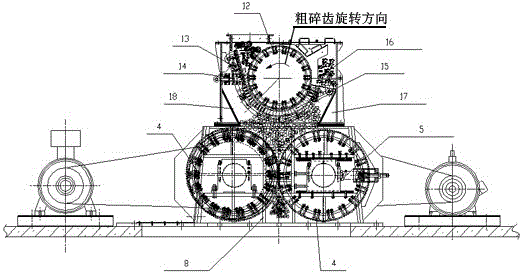

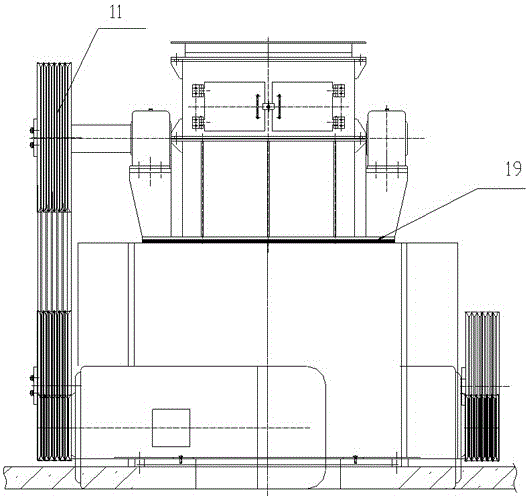

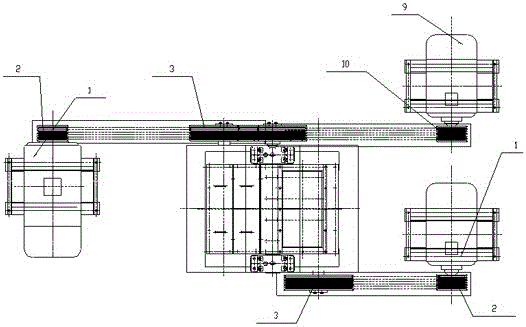

[0037] Disclosed is a comprehensive crusher for sorting impurities for fluidized bed boiler fuel, which is mainly used for producing crushed circulating fluidized bed boiler fuel. The crusher includes a coarse crushing operation area and a fine crushing operation area. The fine crushing operation area is located below the coarse crushing operation area.

[0038] The coarse crushing operation area includes an upper coarse crushing area body 17, and a coarse crushing toothed roller 12 is arranged in the upper coarse crushing area body 17, and the coarse crushing toothed roller 12 can rotate freely in the upper coarse crushing area body 17 and crush the crushed material . A coarse crushing discharge sieve plate 15 is arranged under the coarse crushing toothed roller 12 in the body 17 of the upper coarse crushing area, and a number of sieve holes are provided on the coarse crushing discharge sieve plate 15, and the crushed material after being crushed by the coarse crushing toothe...

Embodiment 2

[0043] On the basis of Embodiment 1, the retreat protection device 14 includes a retreat adjustment rod 141, and the retreat adjustment rod 141 is installed in the through hole on the body 17 of the upper coarse crushing area, and the retreat adjustment rod 141 can be placed in the upper coarse crushing area. The through hole on the body 17 rotates around the axis of the retreat adjustment rod 141 . One end of the adjustment rod 141 passes through the through hole of the body 17 of the upper coarse crushing area and penetrates into the body 17 of the upper coarse crushing area to connect with the nut seat 142 located in the body 17 of the upper coarse crushing area, and between the adjustment rod 141 and the nut seat 142 Through threaded connection, the nut seat 142 can move along the axial direction of the retreat adjustment rod 141 when the retreat adjustment rod 141 is turned. One side of the nut seat 142 is connected with the compression spring 143, and the other end of th...

Embodiment 3

[0045] On the basis of Embodiment 1 or Embodiment 2, a material guide plate 18 is also provided in the body 17 of the upper coarse crushing area. The material guide plate 18 has a V-shaped structure with a large upper opening and a small lower opening. 18 is connected with the inner wall of the upper rough crushing area body 17. The feed inlet of the material guide plate 18 is located below the coarse crushing discharge sieve plate 15, and the discharge port of the coarse crushing discharge sieve plate 15 is located above the fine crushing operation area. The crushed material enters the feed port of the material guide plate 18, and falls into the crushing operation area through the discharge port of the material guide plate 18 for fine crushing treatment. Due to the addition of a material guide plate 18, the crushed materials can be guided through the material guide plate 18, so that the crushed materials can completely enter the lower fine crushing operation area for fine cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com