Method and apparatus for removing oil pollutants contained in catalyst micro-powder in MTO quenching wastewater

A technology for catalysts and pollutants, which is applied in the field of oil-containing catalyst micropowder degreasing, and can solve problems such as cumbersome process, long process, and undeveloped degreasing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

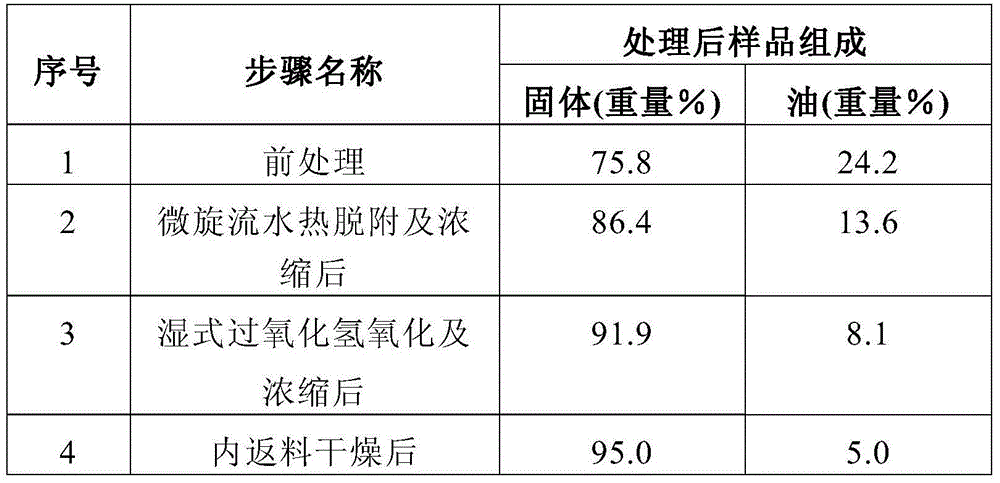

[0088] In a 600,000 tons / year MTO device, according to the method of the present invention, the oil-containing catalyst micropowder slurry in the pre-treated MTO quenched wastewater is deoiled, and its specific implementation process and degreasing effect are described as follows:

[0089] 1. Properties of oil-containing catalyst powder slurry:

[0090] During the normal operation of the MTO unit, the total weekly production of oil-containing catalyst micropowder slurry is 10.08 tons (dry basis), including 2.42 tons of oil.

[0091] The particle size of the catalyst micropowder is 3 μm, the water content is 3% by weight, and the oil content is 24.0% by weight (all based on catalyst weight); the specific surface area is 58m 2 / g, the pore volume is 0.019ml / g.

[0092] The oil pollutants adsorbed by the catalyst powder are mainly polymer alkanes, aromatics, ketones, esters, etc.

[0093] 2. Implementation process:

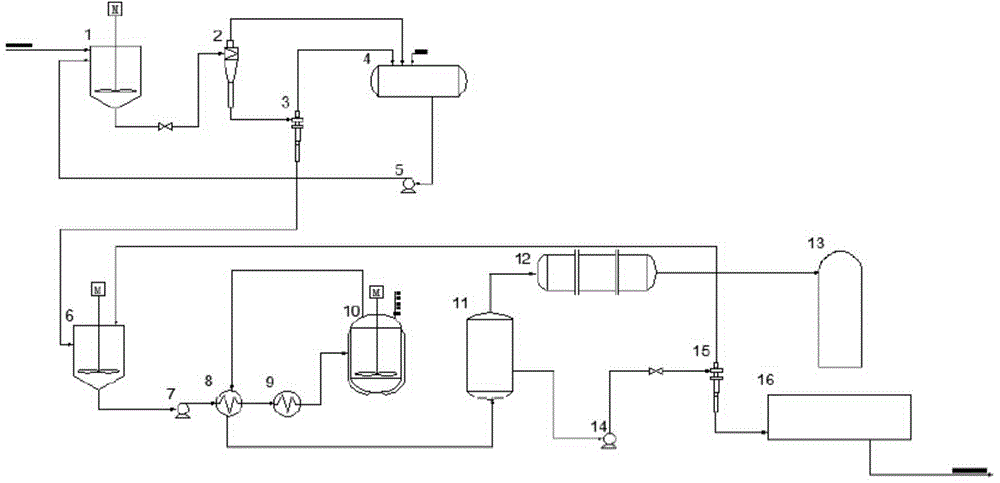

[0094] see figure 1 . With reference to the specific imple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com