High stubble and thick straw resistant non-tillage seeder

A seeder and straw technology, applied in the field of agricultural machinery, can solve problems such as congestion, withering, and yellowing of emerging seedlings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

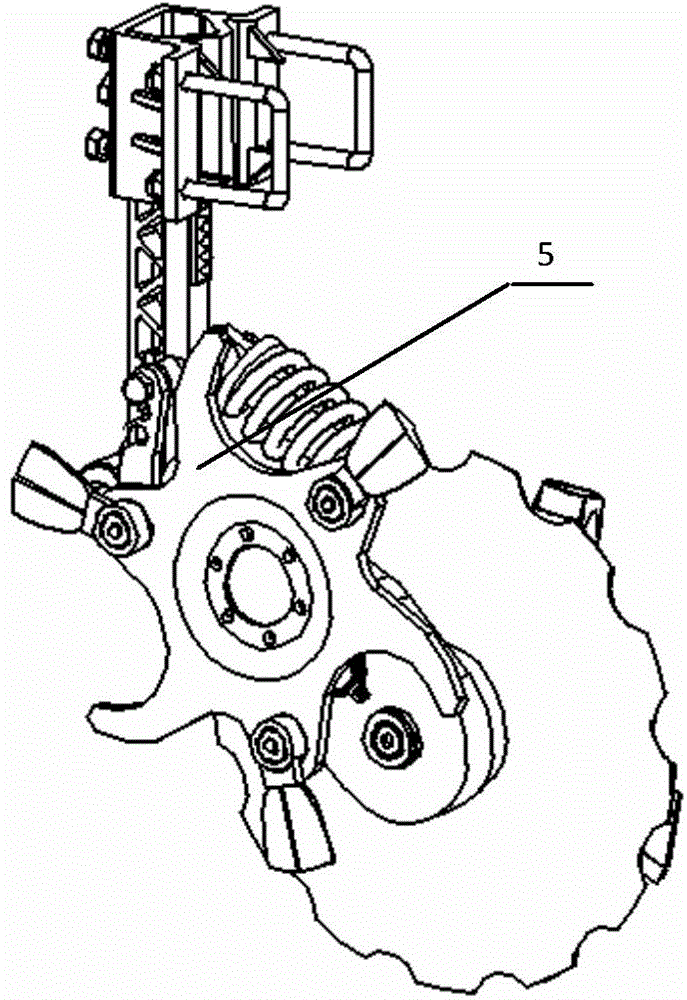

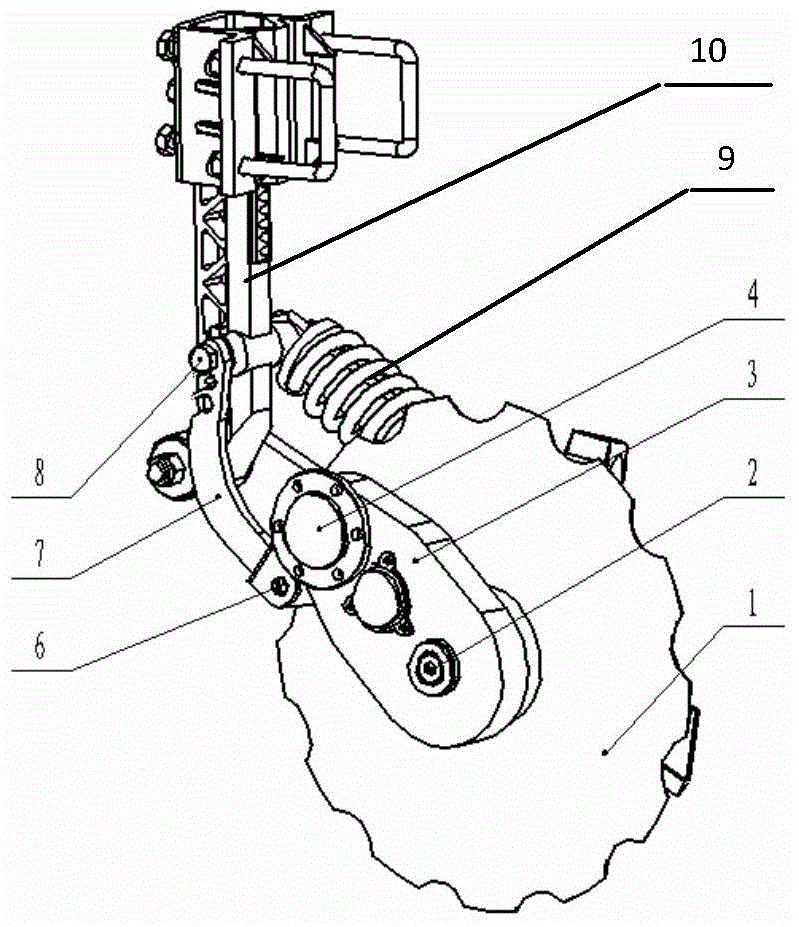

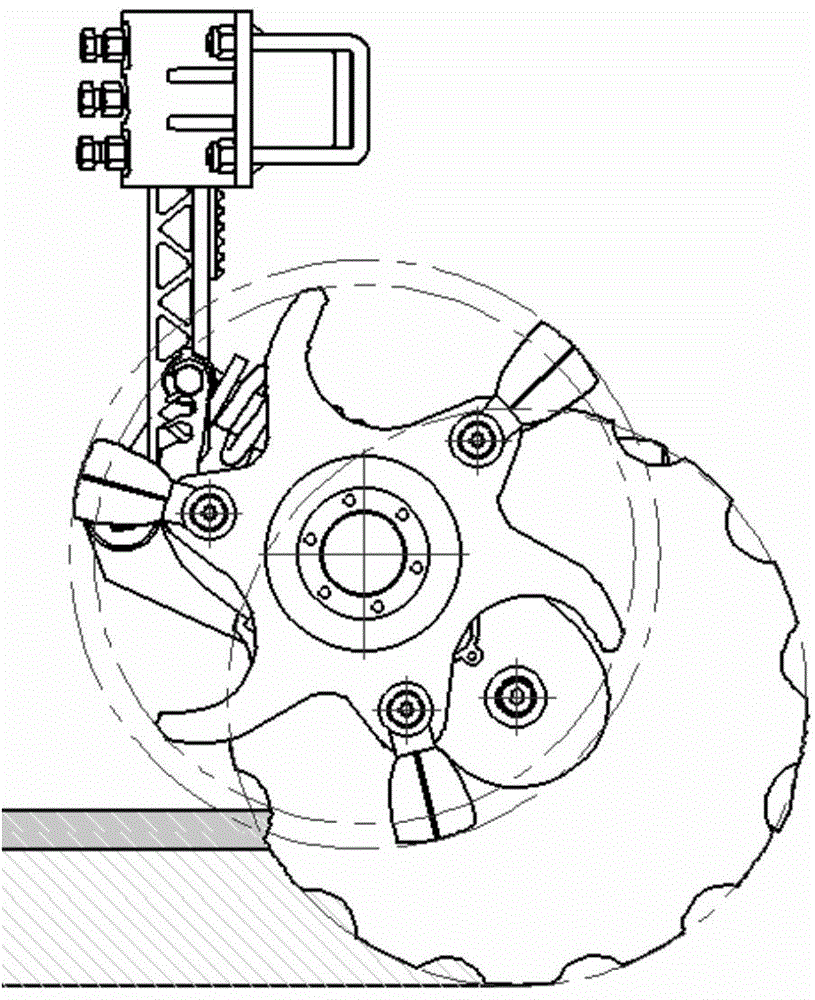

[0021] The invention provides a no-tillage seeder resistant to high stubble and thick stalks, which is the same as the prior art in that it includes a frame and a movement along the no-tillage seeder. The directions are successively arranged on the frame for fertilizing and ditching notched disc supports and sowing supports; the fertilizing and ditching notched disc supports are provided with fertilizing and ditching notched discs; the sowing supports are sequentially arranged with Sowing and ditching discs and sowing discs; the key difference from the prior art is that the present invention moves the position of the anti-congestion device forward, directly moving forward from the existing sowing and ditching discs to the fertilization and ditching notch discs On the support, that is, the no-tillage seeder also includes an anti-crowding device that is arranged on the fertilization ditching notch disc support and parallel with the fertilization ditching notch disc; the anti-crow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com