High-precision frequency linear-tuning narrow-linewidth laser device

A frequency linear and laser technology, which is applied in the direction of devices for controlling laser output parameters, lasers, laser components, etc., can solve the problems of tunable laser output power and limited tuning range, and achieve an increase in output frequency range, easy implementation, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

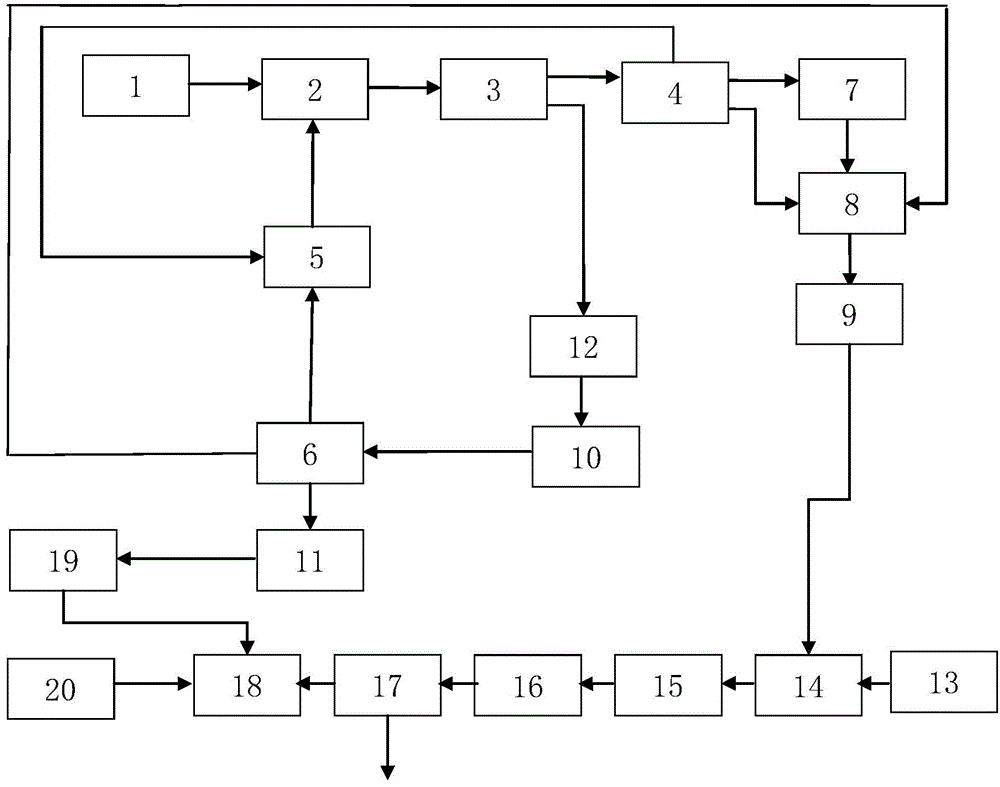

[0033] First please refer to figure 1 , figure 1 It is a block diagram of the overall structure of the high-precision frequency linearly tuned narrow linewidth laser device of the present invention. Depend on figure 1 It can be seen that the high-precision frequency linearly tuned narrow linewidth laser device of the present invention comprises a reference crystal oscillator 1, a frequency and phase detector 2, a loop filter 3, a voltage-controlled oscillator 4, a programmable frequency divider 5, and a controller 6 , frequency multiplier 7, high-speed switch 8, microwave amplifier 9, analog-to-digital converter 10, digital-to-analog converter 11, second low-pass filter 12, narrow linewidth fiber laser 13, electro-optic modulator 14, tunable attenuator 15. Tunable optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com