Profile steel cement soil pile construction method adaptive to various stratums

A cement-soil pile and cement-soil technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems affecting underground engineering construction, difficulty in large-scale promotion and use, and difficulty in ensuring uniformity, achieving significant resource saving benefits , Reliable construction quality, fast and non-destructive recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

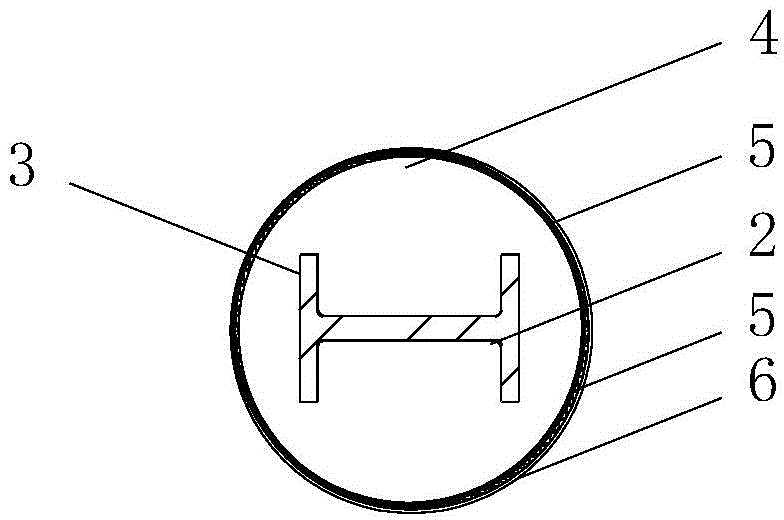

[0034] Combine below figure 1 , figure 2 The present invention is described in further detail:

[0035] 1. Steel cement soil pile:

[0036] Such as figure 1 , figure 2 It can be seen that the shaped steel cement soil pile placed in the foundation soil 1 is composed of shaped steel 2, cement soil 4, vaseline or release agent 3, mud skin 5, and borehole 6;

[0037] From bottom to top, drill hole 6 is connected with mud skin 5, mud skin 5 is connected with cement soil 4, cement soil 4 is connected with vaseline or release agent 3, vaseline or release agent 3 is connected with section steel 2, section steel 2 is connected with installation The short steel beam 10 with slips is connected to the hook 11, the short steel beam 10 equipped with slips is connected to the jack 8, the jack is connected to the automatic oil pump through the oil pipe 9, the hook 11 is connected to the wire rope 12, and the wire rope 12 is connected to the excavator The digging head is connected.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com