Alloy material for turboset rotor and preparation method thereof

A technology of alloy materials and steam turbines, which is applied in medium pressure rotor alloy materials and its preparation, alloy materials of steam turbine rotors and its preparation, and ultra-supercritical steam turbine high pressure field, which can solve the problems that the high-temperature durability of materials is difficult to meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The embodiment of the present invention includes the following steps.

[0035] 1. Preparation of electroslag ingot

[0036] (1) Weigh the raw materials according to the proportion, and smelt them in a vacuum induction furnace. During the smelting process, adjust the content of the chemical elements so that the weight percentages are as shown in Table 1.

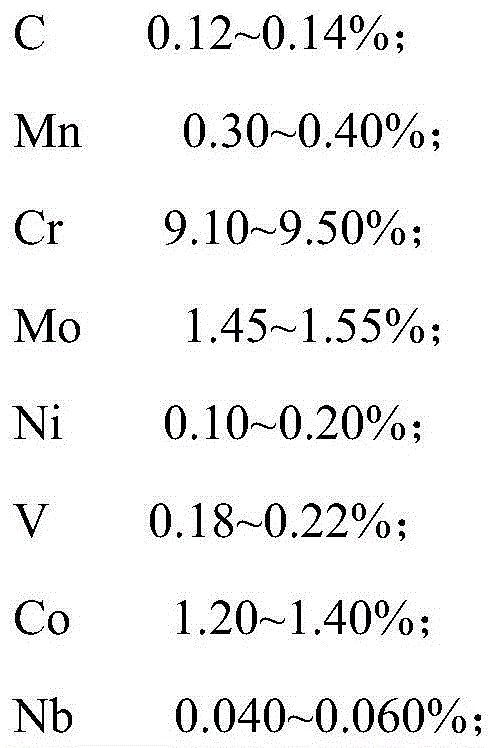

[0037] The weight percent of table 1 embodiment 1-5

[0038]

[0039] During the smelting process, the content of impurity elements is controlled as low as possible, and the solution obtained from smelting is poured into a consumable electrode.

[0040] (2) Place the prepared consumable electrode in an electroslag furnace for remelting and refining to further reduce the content of impurity elements so that it meets the following requirements:

[0041] 0.12-0.14wt% C; 0.30-0.40wt% Mn;

[0042] 9.10-9.50wt% Cr; 1.45-1.55wt% Mo;

[0043] 0.10-0.20wt% Ni; 0.18-0.22wt% V;

[0044] 1.20-1.40wt% Co; 0.040-0.060wt% Nb;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com