Intelligent preparation system and preparation method for synthesizing quick-acting and slow-release integrated efficient ecological compound fertilizer through straw microbial fermentation

An intelligent preparation system and microbial fermentation technology, applied in the field of biological fermentation of agricultural straw resources, to achieve the effects of improving fermentation efficiency, maintaining activity, and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

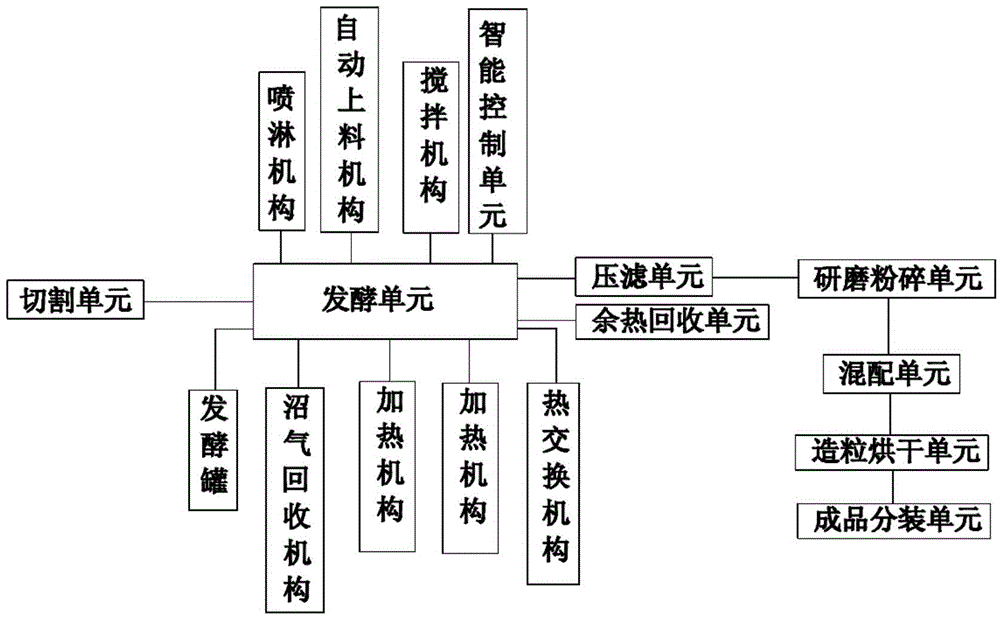

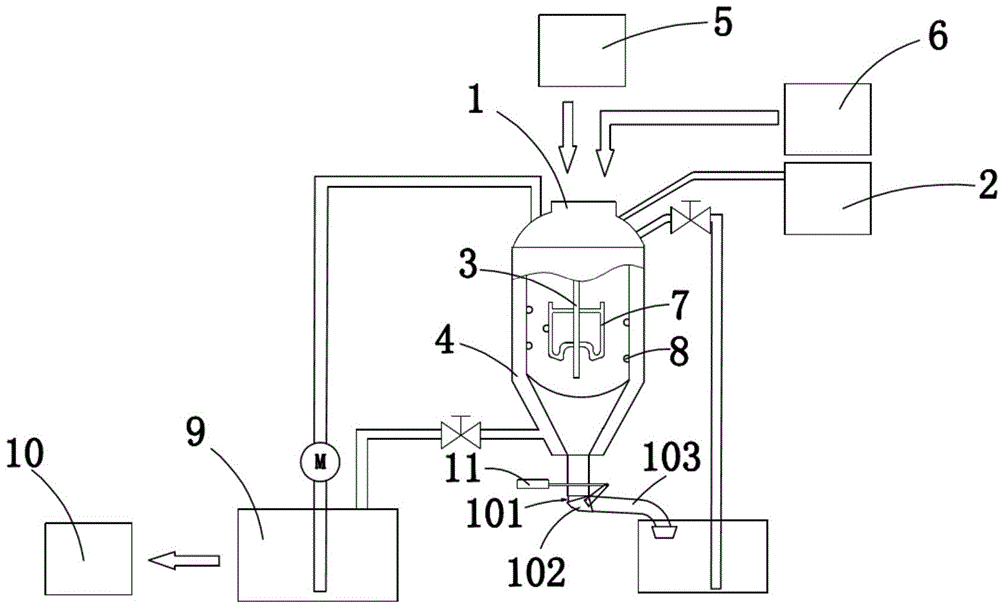

[0040] As shown in the figure, a straw ecological compound fertilizer intelligent preparation system includes a cutting unit, a fermentation unit, an intelligent control unit, a waste heat recovery unit, a filter press unit, a grinding and crushing unit, a mixing unit, a granulation and drying unit and a finished product classification unit. The fermentation unit includes a fermentation tank 1, a biogas recovery mechanism 2, a heating mechanism 3, a heat exchange mechanism 4, a spray mechanism 5, an automatic feeding mechanism 6, a stirring mechanism 7 and an intelligent temperature control unit. The intelligent temperature control unit includes a temperature The sensor 8 and the intelligent control chip, the fermenter has a cavity for straw fermentation, the temperature sensor 8 and the stirring mechanism 7 are set in the cavity, wherein there are multiple temperature sensors 8, which can be distributed on the inner wall of the cavity and the stirring mechanism , the intellige...

Embodiment 2

[0047] A method for preparing high-efficiency ecological fertilizer by microbial fermentation of straw, using biological straw as the main raw material and animal manure as the starter, the specific preparation method is as follows:

[0048] S1. Cut the waste biological straw into straw sections with a length of 5-10cm, and load it into the fermenter from the feeding port on the top of the fermenter with an automatic feeding mechanism, and then use 10 times of the fresh animal manure according to the ratio of 2% of the straw weight After dilution and stirring with water, it is sprayed onto the straw in the tank through the spraying mechanism, and the stirring mechanism is started to mix the feces liquid and the straw evenly; when initially feeding, use the heating mechanism to rapidly raise the temperature in the tank to above 30°C, and then carry out closed natural fermentation , the fermentation period is 3-5 days; during the fermentation period, the temperature in the tank i...

Embodiment 3

[0056] A method for preparing quick-acting slow-release integrated high-efficiency ecological fertilizer by using straw microbial fermentation, the steps are the same as in Example 2, the difference is that step S4 is: add 25-30% clay dry powder to the straw powder obtained by grinding step S3 according to its weight , 15-20% inorganic fertilizer, mixed and stirred evenly, granulated by a granulator, ventilated, dried and dried to obtain an ecological compound fertilizer. Inorganic fertilizer is any one or more combinations of N fertilizer, P fertilizer, potassium fertilizer or other inorganic fertilizers acceptable to crops, and its combination ratio can also be reasonably adjusted according to the different soil properties in the area where the fertilizer is used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com