Rubber belt cooling production line

A production line and rubber belt technology, applied in the field of rubber belt cooling production line, can solve the problems of high labor intensity, affecting the cutting procedure, and low cooling effect, and achieve the effect of reducing labor intensity, good cooling effect, and ensuring cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

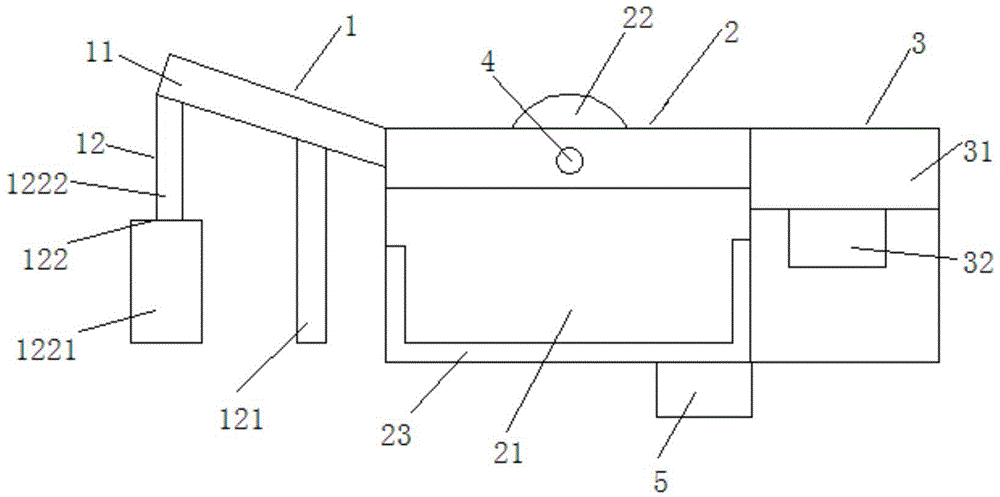

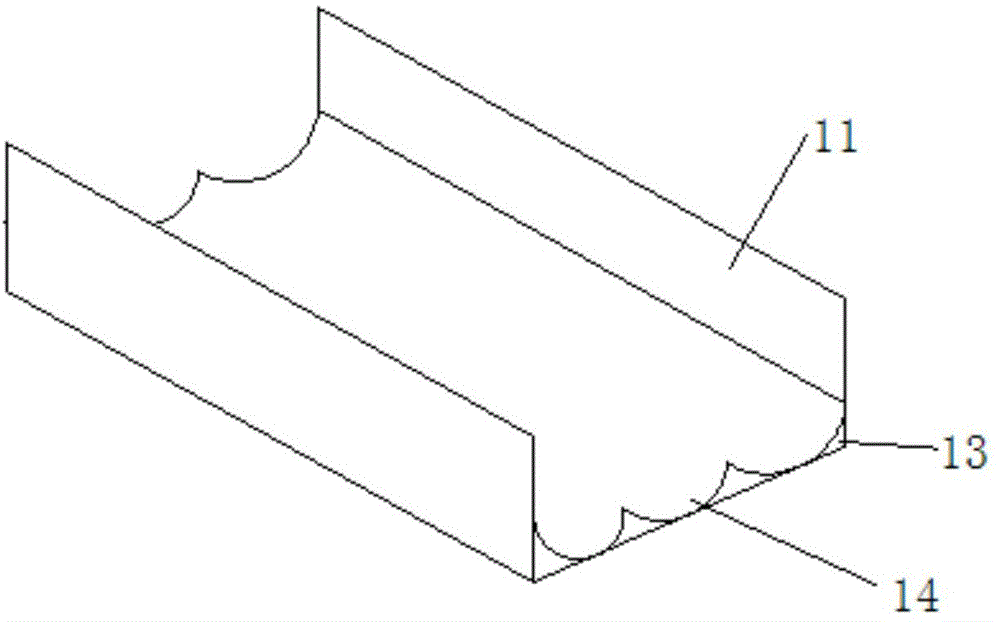

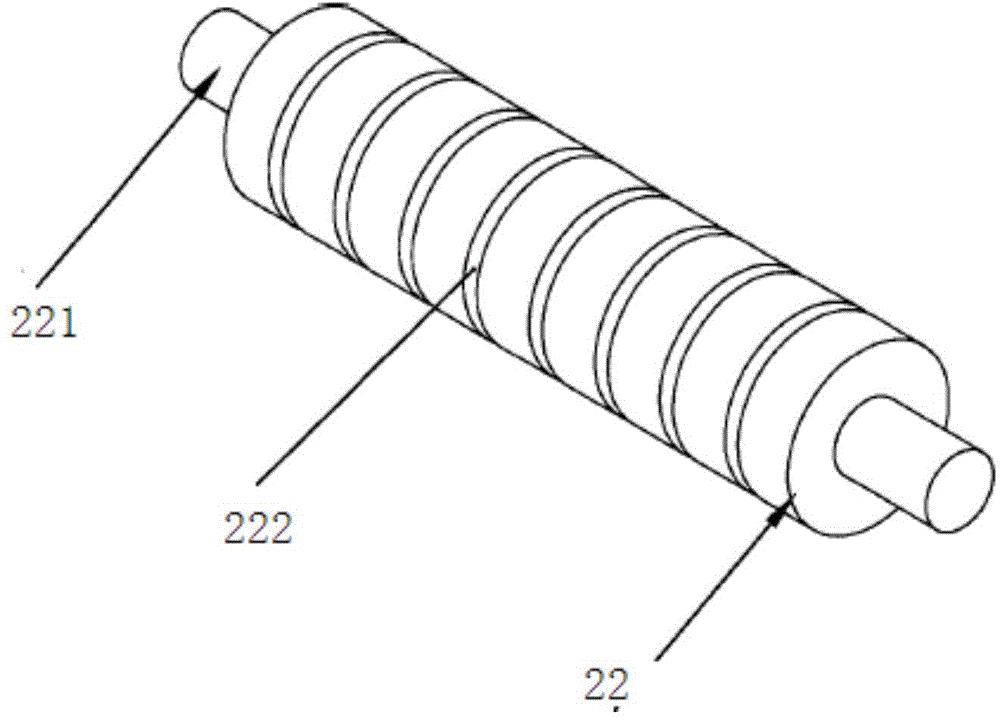

[0014] See attached figure 1 , attached figure 2 And attached image 3 , a rubber belt cooling production line, comprising a material introduction device 1, a cooling device 2 and an air-drying device 3, the material introduction device 1 is arranged in front of the cooling device 2, and the air-drying device 3 is arranged behind the cooling device 2, and the material introduction device 1 includes a material introduction Plate 11 and support column 12, conveyer belt 13 is provided on the feeder plate 11, and the surface of conveyer belt 13 is provided with arc-shaped material introduction groove 14, and described support column 12 comprises fixed column 121 and the adjustment column 122 that can adjust height, The adjustment column 122 includes a fixed seat 1221 and a telescopic rod 1222. The cooling device 2 includes a cooling water tank 21, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com