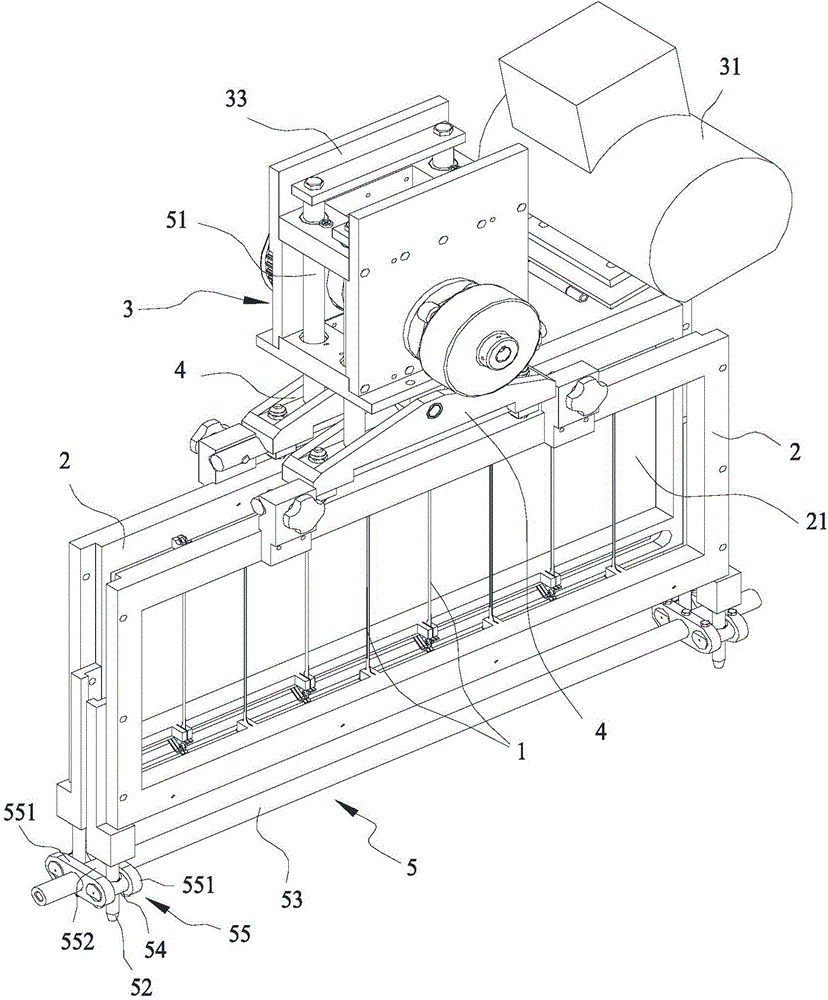

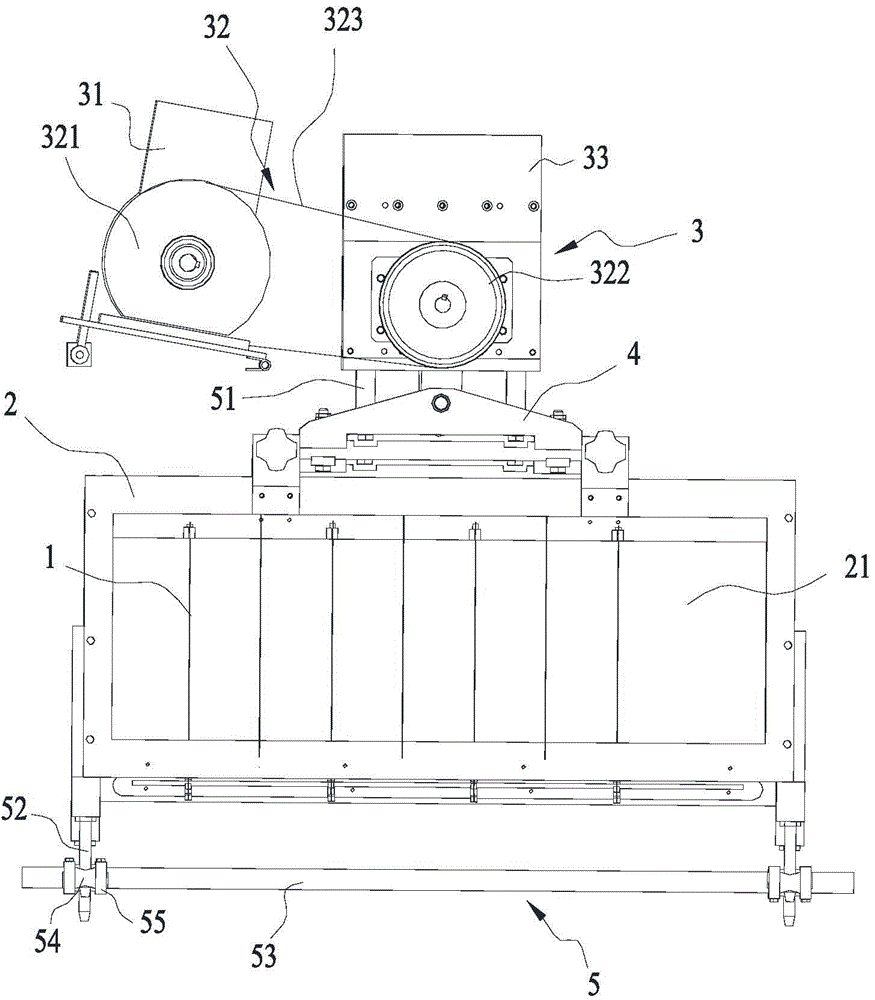

Food slicing mechanism

A food and slicing technology, which is applied in the division/slicing of baked food, metal processing, etc., can solve the problems of incision deformation, food force imbalance, large slice size error, etc., to prevent extrusion deformation and balance food taste , the effect of balanced cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

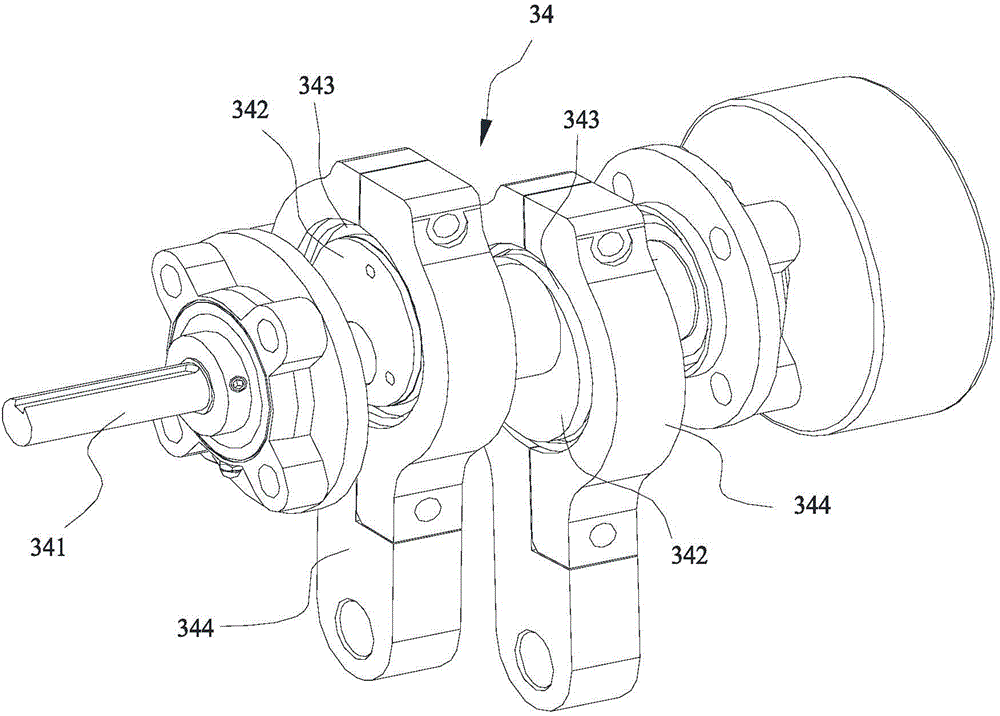

[0029] The driving mechanism 3 can also adopt a preferred embodiment of the present invention: the driving mechanism 3 includes a motor 31, a transmission mechanism 32, a mounting frame 33, and an eccentric mechanism 34. The eccentric mechanism 34 is pivotally mounted in the mounting frame 33. The eccentric mechanism 34 It is connected to the tool post 2 in transmission and is used to provide reciprocating driving force to the tool post 2; the motor 31 is in transmission connection with the eccentric mechanism 34 through the transmission mechanism 32 and is used to drive the eccentric mechanism 34 to operate. Through the operation of the eccentric wheel mechanism 34, a reciprocating driving force is generated by the protrusion of the eccentric wheel 342 in the eccentric wheel mechanism 34 to drive the tool holder 2 to move back and forth. The operation mode of the eccentric wheel mechanism 34 can reduce the cost, and at the same time help maintain the stable frequency of the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com