Mechanical butt assembly alignment adjusting device

A counterpoint adjustment and mechanical technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as unfavorable streamlined operations, high risk of personal injury safety accidents in lifting operations, and heavy component weight, etc., to achieve Achieve operation standardization and streamline operation, reduce the safety risk of personal injury accidents, and improve the efficiency of alignment adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

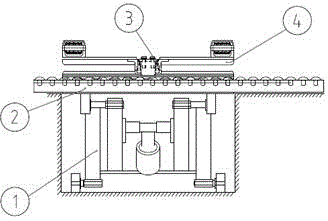

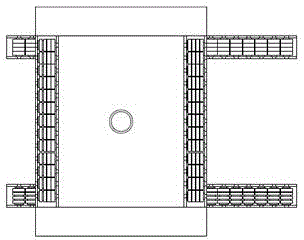

[0025] Such as figure 1 , 2 , 3, the supporting platform is used to support the workpiece, and the supporting platform is provided with a Y-axis moving pair 4, and the supporting platform is connected to a rotating pair 3, an X-axis moving pair 2, and a Z-axis moving pair The adjustment mechanism of 1 makes the support table have the function of moving in the directions of X, Y and Z axes and rotating along the Z axis to adjust the position of the workpiece.

[0026] In the adjustment mechanism, the moving end of the rotating pair 3 is connected to the support platform, the moving end of the X-axis moving pair 2 is connected to the fixed end of the rotating pair 3, and the moving end of the Z-axis moving pair 1 The moving end is connected to the fixed end of the X-axis moving pair 2, and is formed by connecting the Z-axis moving pair 1, the X-axis moving pair 2, the rotating pair 3, and the Y-axis moving pair 4 from bottom to top. Adjustment device.

[0027] The fixed end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com