Quick connection die and method for hot rolled strip intermediate billets

A hot-rolled strip, quick-connection technology, applied in forming tools, metal rolling, manufacturing tools, etc., can solve the problems of low strength, large equipment investment and maintenance costs, and small application scope, and achieve high connection strength and fast connection. Simple effect of connection, process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0046] In order to solve the problems of small application range, low strength and large equipment investment in the existing technology, the embodiment of the present invention provides a hot-rolled strip with simple process equipment, high connection strength, fast connection speed and wide application range. Quick-connect dies for steel blanks.

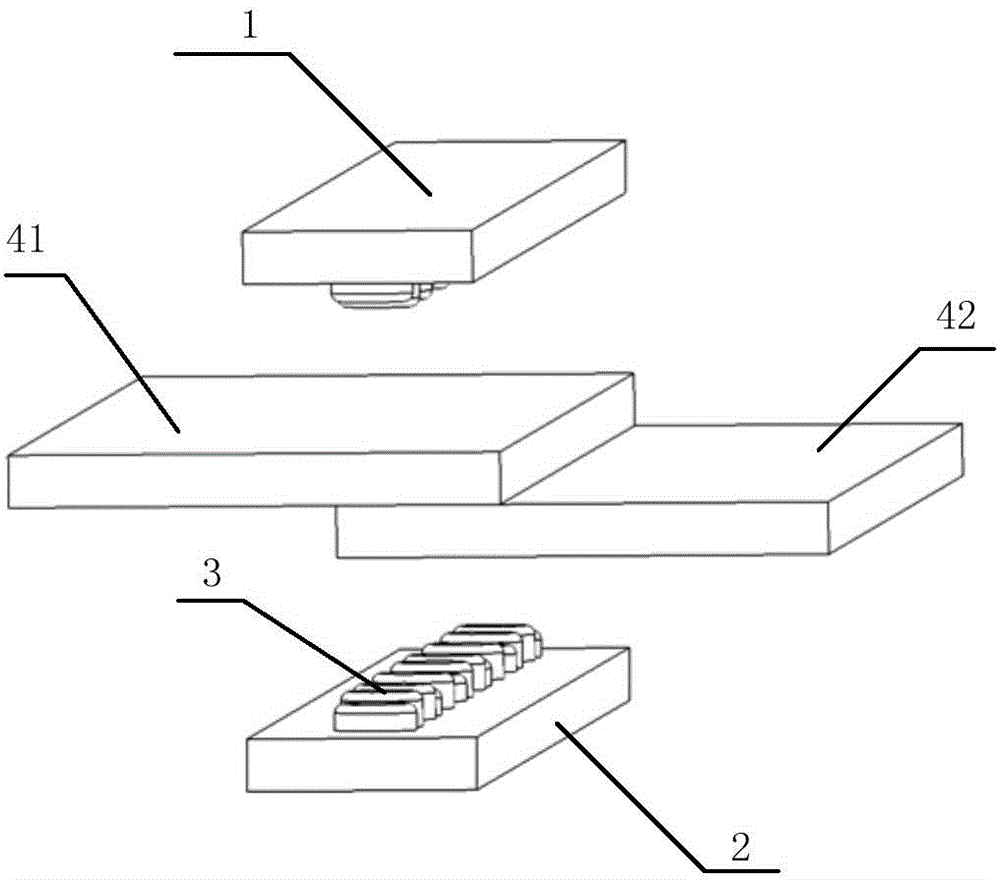

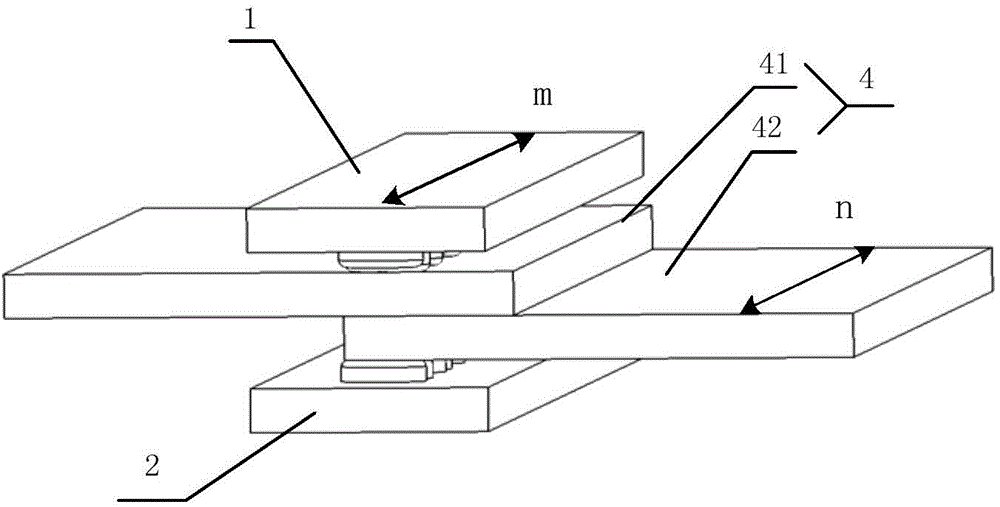

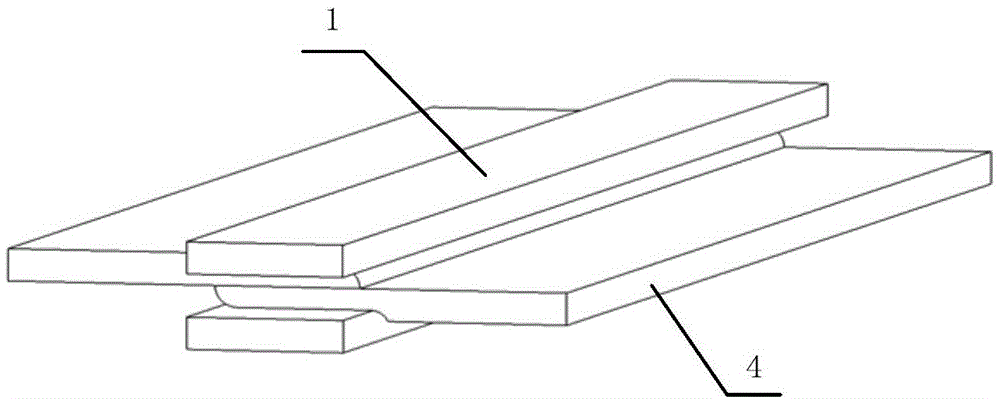

[0047] Such as figure 1 As shown, the quick connection die of the hot-rolled strip intermediate billet provided by the embodiment of the present invention includes an upper die 1 and a lower die 2; the upper die 1 and the lower die 2 are engaged with each other; the meaning of mutual engagement is exactly Close to each other during use, and the convex part of the mold on the horizontal plane is completely fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com