Preparation method of supported ferric activated carbons as well as condition and device applying supported ferric activated carbons to absorb methylbenzene

A technology of iron-loaded activated carbon and activated carbon, which is applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problem of small adsorption capacity of activated carbon, and achieve the effect of improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

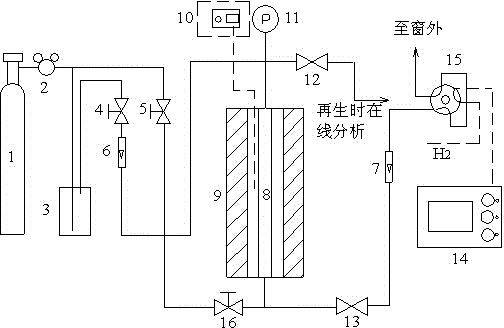

Method used

Image

Examples

preparation example Construction

[0041] A preparation method for iron-loaded activated carbon, comprising the steps of:

[0042] (1) Preparation of impregnation solution: dissolve the weighed iron salt in 0.1-10mol / L acid solution, and prepare the impregnation solution at a temperature of 20-80°C;

[0043] Wherein, the iron salt is one or more mixtures of ferric chloride, ferric nitrate, ferric sulfate, ferric acetate and ferric oxalate, preferably ferric chloride.

[0044] The acid solution is preferably 1mol / L hydrochloric acid solution.

[0045] (2) Impregnation of activated carbon: using the equal volume impregnation method or excessive impregnation method, impregnate activated carbon with a particle size of 150 μm to 1700 μm in the above impregnation solution, and the mass ratio of iron element to activated carbon after impregnation is 0.025 to 0.35;

[0046] Among them, the activated carbon can be selected from one or a combination of wood, coal, fruit shell and coconut shell granular activated carbon....

Embodiment 1

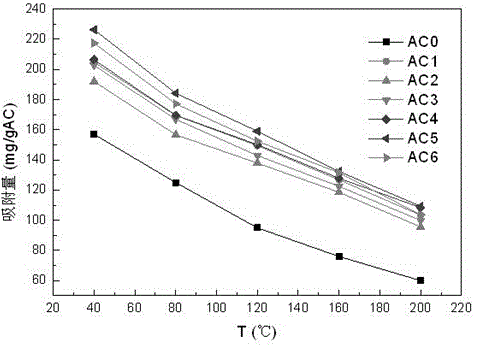

[0066] Embodiment one: take 20~40 purpose coconut shell activated carbons as example (unloaded activated carbon is denoted as AC 0 ), dissolving ferric chloride in a certain volume of 1mol / L HCl solution, and then AC 0 dipped in it. The mass ratios of iron and activated carbon in the impregnation system were 0.028:1, 0.056:1, 0.084:1, 0.112:1, 0.224:1, and 0.336:1, respectively. denoted as AC 1 、AC 2 、AC 3 、AC 4 、AC 5 and AC 6 .

[0067] AC 0 、AC 1 、AC 2 、AC 3 、AC 4 、AC 5 and AC 6 The adsorption experiments of toluene were carried out, and the adsorption conditions were as follows: the toluene content in the toluene gas source was 5%, the adsorption pressure was 0.2MPa, and the gas flow rate was 250mL / min.

[0068] Under the same adsorption conditions and different loads, the adsorption capacity of iron-loaded activated carbon to toluene is shown in Table 1 and figure 2 shown.

[0069] Table 1: Adsorption characteristics of adsorbents with different loadings ...

Embodiment 2

[0072] Example 2: Dissolve ferric chloride in a certain volume of 1mol / L HCl solution, and then impregnate activated carbon AC in it. The mass ratio of iron to activated carbon in the impregnation system is 0.05:1. Drying in medium temperature, and then the adsorption experiment of toluene was carried out.

[0073] The toluene content in the toluene gas source is 3%, the adsorption pressure is 0.8MPa, the gas flow rate is 250mL / min, the adsorption temperature is 80°C, and the saturated adsorption capacity of toluene reaches 190.4mg / g activated carbon, which is higher than that of unmodified activated carbon under the same conditions. The amount of activated carbon was 131.54 mg / g, an increase of 44.75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| adsorption temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com