Metal film differential pressure filter

A metal membrane and filter technology, which is applied in the direction of filtration separation, gravity filter, fixed filter element filter, etc., can solve problems such as long backwashing time, limited filtration efficiency and effect, and failure to restore the flux of the filter in time. Achieve the effect of low water consumption and short duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

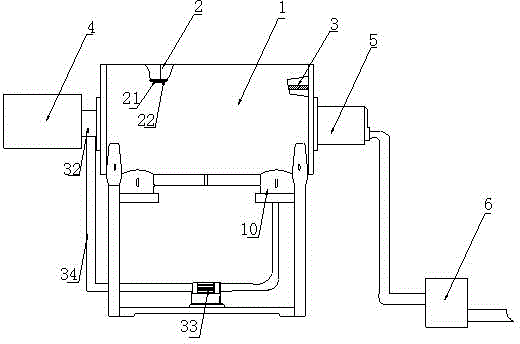

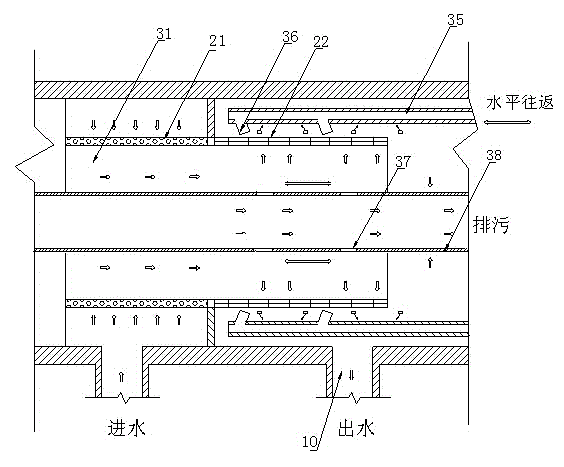

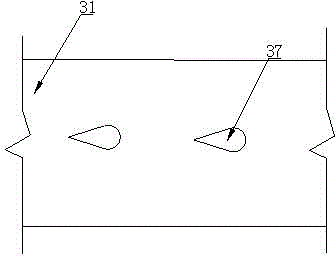

[0013] like figure 1 , figure 2 As shown, the metal membrane differential pressure filter includes a body 1, a filter system 2 located in the body 1, a backwash system 3 located in the filter system 2, a transmission system 4 connected to the backwash system 3, and located in the filter system 2. The sewage system 5; the filter system 2 is a cylindrical structure with mesh holes, including 21 sections of coarse filter screen and 22 sections of fine filter screen. , the backwash system 3 includes a hollow shaft 31 that is coaxial with the body 1, the front end of the hollow shaft 31 is connected to the transmission system 4, and the front end of the hollow shaft 31 is a high-pressure water inlet chamber 32; The water pipe 34 supplies water to the body 1, the high-pressure backwash pump 33 is communicated with the water product outlet 10 of the body 1, and the high-pressure backwash pump water inlet pipe 34 is communicated with the high-pressure water inlet chamber 32; The hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com