Method for using graphene to determining copper substrate surface crystal orientation

A technology of copper substrate and graphene, which is applied in the direction of analyzing materials through chemical reactions, can solve the problems of high cost and complicated judgment steps, and achieve the effect of low cost and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

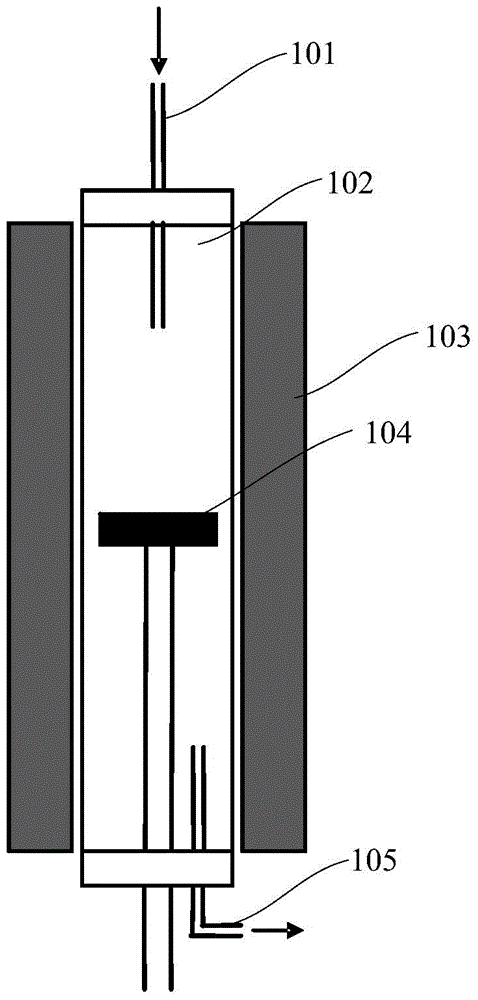

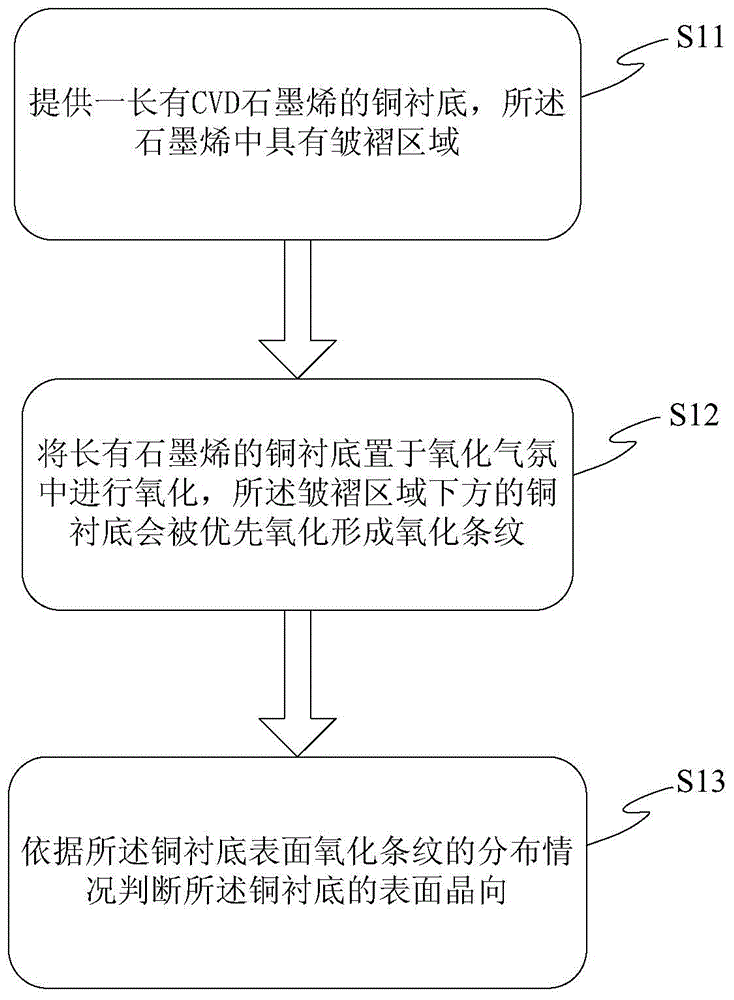

[0034] Such as Figure 1 ~ Figure 2 As shown, the present embodiment provides a method for determining the crystal orientation of a copper substrate surface using graphene, at least including the following steps:

[0035] Such as figure 2 As shown, step 1) S11 is first performed to provide a copper substrate with CVD graphene, and the graphene has wrinkled regions.

[0036] As an example, the copper substrate is a polycrystalline copper substrate. In addition, the present invention is also applicable to all other polycrystalline metal substrates suitable for growing graphene and capable of being oxidized, such as cobalt and nickel.

[0037] Large-area continuous graphene can be obtained by chemical vapor deposition, but the graphene prepared by this method often has more wrinkled regions.

[0038] As an example, the graphene is a graphene continuous film or a graphene single crystal. And, described graphene continuous film can be monolayer graphene continuous film or mult...

Embodiment 2

[0049] Such as Figure 1 ~ Figure 2 As shown, this embodiment provides a method for determining the crystal orientation of a copper substrate surface using graphene, wherein the graphene is a graphene single crystal, oxidized by air, and oxidized at normal pressure and at a temperature of 200° C. for 30 minutes .

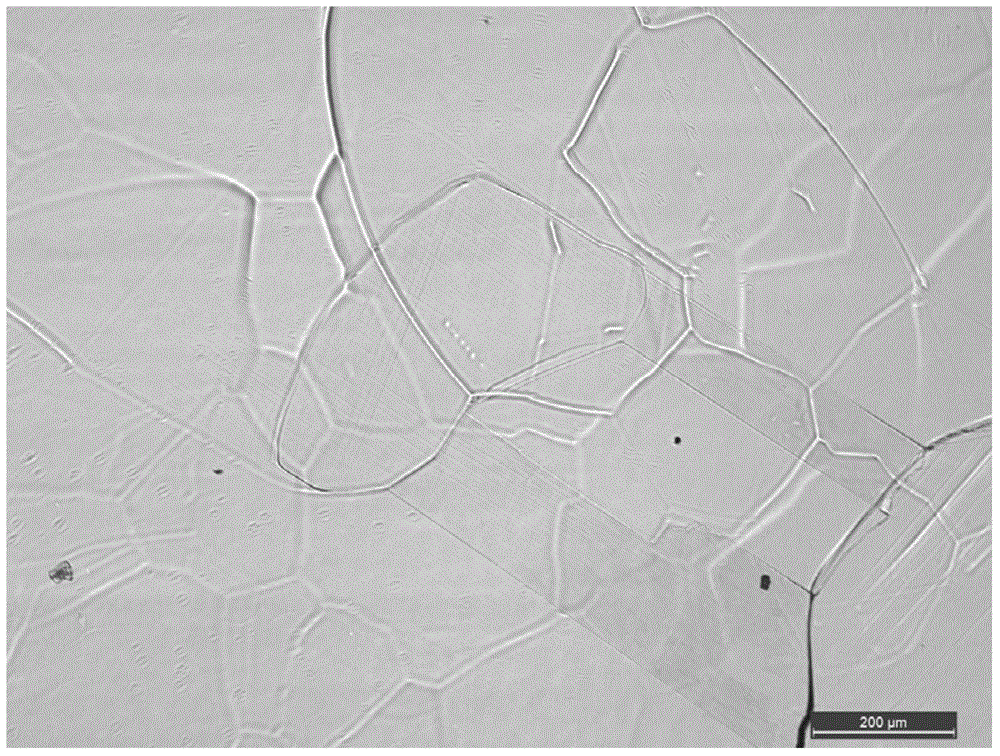

[0050] Figure 5 and Figure 6 Respectively, the copper substrate with graphene is treated by the present embodiment before and after the light microscope. Compared Figure 5 and Figure 6 It can be clearly found that after the treatment of this embodiment, the color of the copper surface without the graphene single crystal protection area has changed significantly, indicating that the copper surface in these areas is severely oxidized, while the color of the area protected by the graphene single crystal There is no significant change, indicating that graphene has a better anti-oxidation protection ability for copper. In addition, darker oxidation stripes appe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com