Test method for poisson ratio of continuous fiber enhanced resin-based composite material

A technology for strengthening resin-based and composite materials, which is applied in the preparation of test samples and the use of stable tension/pressure to test the strength of materials, etc., which can solve the problems of reduced test accuracy, optical signal intensity attenuation, and experimental result errors, etc., to achieve Improve surface quality and dimensional accuracy, improve reliability and stability, and solve the effect of poor shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A continuous fiber reinforced resin matrix composite material Poisson's ratio fiber Bragg grating string test method.

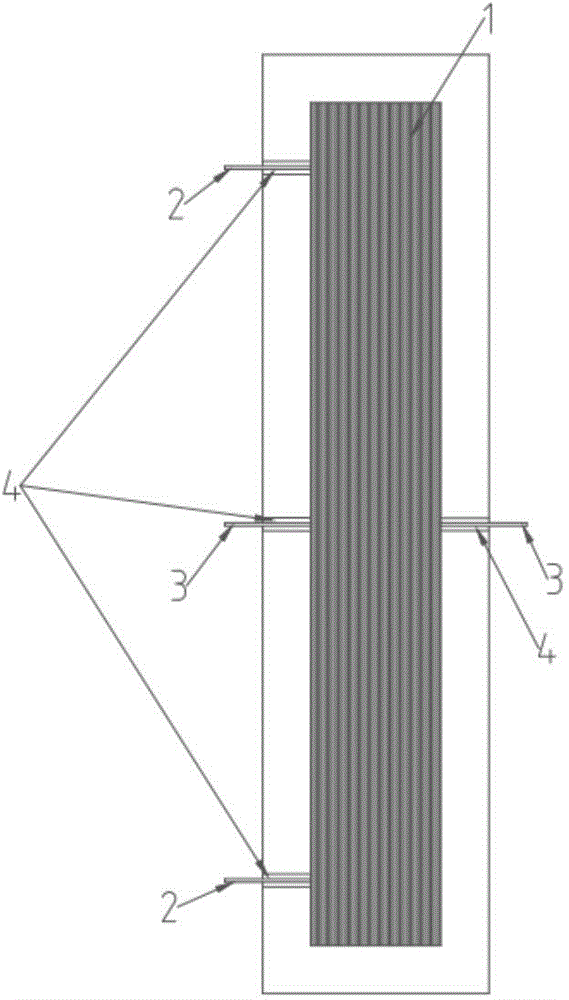

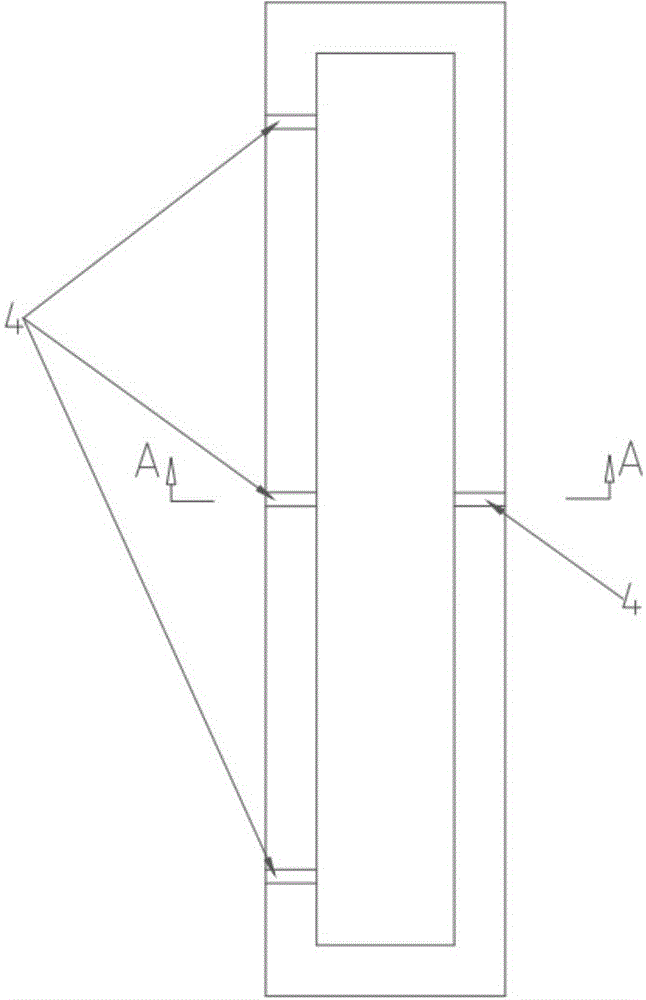

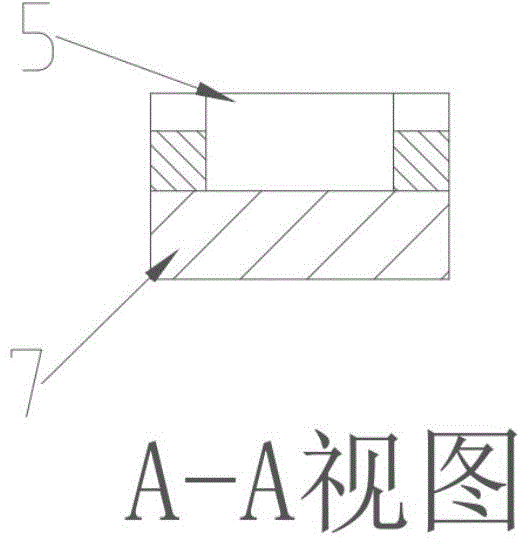

[0049] (1) Preparation of composite standard test piece: Wrap a layer of PTFE tape uniformly on the entire mold frame 5 and its lead groove 4, and then cover a layer of PTFE cloth. Lay N layers (N≥20) of resin-based composite material prepreg 1 in the mold cavity, and lay fiber Bragg grating strings on the two prepreg layers, that is, on the nth layer (N-10> n>5) Lay a fiber Bragg grating string 2 in the longitudinal direction (0° direction of the fiber), and lay a narrow stripe, same type on the n+i layer (N-14≥i>5) in the transverse direction (90° direction of the fiber). The fiber Bragg grating string 3 protected by the prepreg 8 has the same fiber direction as the fiber Bragg grating string 3, and the thickness is the same as the thickness of the entire prepreg, which is 0.1~ 0.2mm, rectangular in shape; 6 grating areas are distributed on the longitud...

Embodiment 2

[0064] A continuous fiber reinforced resin matrix composite material Poisson's ratio fiber Bragg grating string test method.

[0065] (1) Preparation of composite standard test piece: Wrap a layer of PTFE tape uniformly on the entire mold frame 5 and its lead groove 4, and then cover a layer of PTFE cloth. Lay N layers (N≥20) of resin-based composite material prepreg 1 in the mold cavity, and lay fiber Bragg grating strings on the two prepreg layers, that is, on the nth layer (N-10> n>5) Lay a fiber Bragg grating string 2 in the longitudinal direction (fiber 0° direction), and lay a narrow strip in the n+i layer (N-14≥i>5) transversely (fiber 90° direction) in the same direction The fiber Bragg grating string 3 protected by the prepreg 8. The narrow strip-shaped, co-directional prepreg 8 has the same fiber direction as the fiber Bragg grating string 3, and the thickness is the same as the thickness of the entire prepreg, which is 0.1~0.2 mm, the shape is rectangular; 4 grating ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com