A low pressure differential opening check valve

A technology of check valve and low pressure difference, which is applied in the direction of lifting valve, valve detail, control valve, etc., and can solve the problems of inability to open, reduced driving force, and inability of the valve to fully open, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

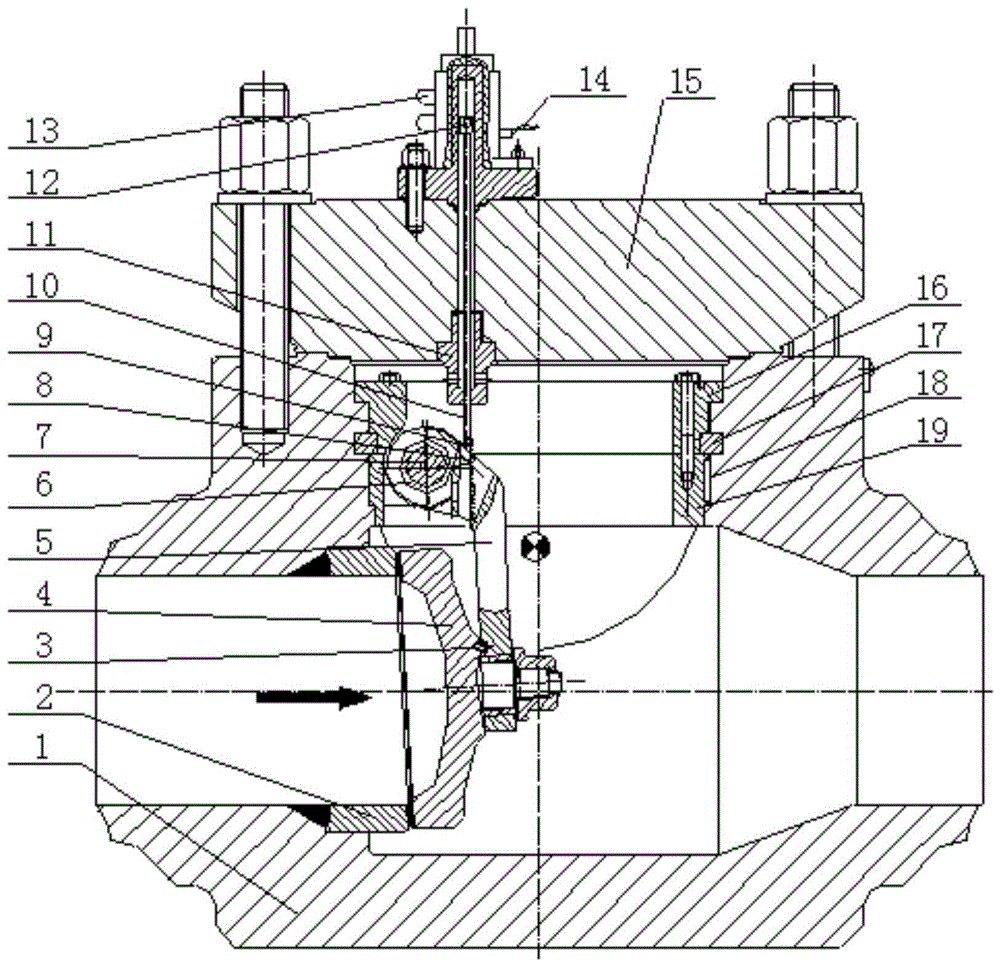

[0029] see figure 1 In order to better understand the technical solutions of the present invention, the following describes in detail through specific embodiments and in conjunction with the accompanying drawings:

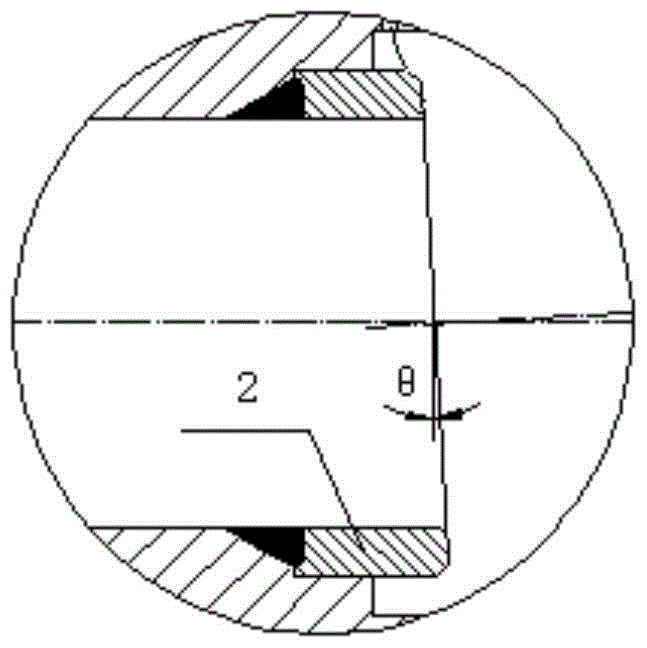

[0030] see figure 1 , A low-pressure differential opening check valve of the present invention includes a valve body 1, a valve seat 2, a valve flap 4, a rocker arm 5, a rocker arm shaft 7, an indicator rod 10, a permanent magnet 12, a valve cover 15, and a sensor 13. , the arrow in the figure indicates the flow direction of the medium through the valve.

[0031] A layer of upper bushing 6 is provided outside the rocker shaft 7 .

[0032] The rocker arm 5 is sleeved on the rocker arm shaft 7 provided with the upper bushing 6 .

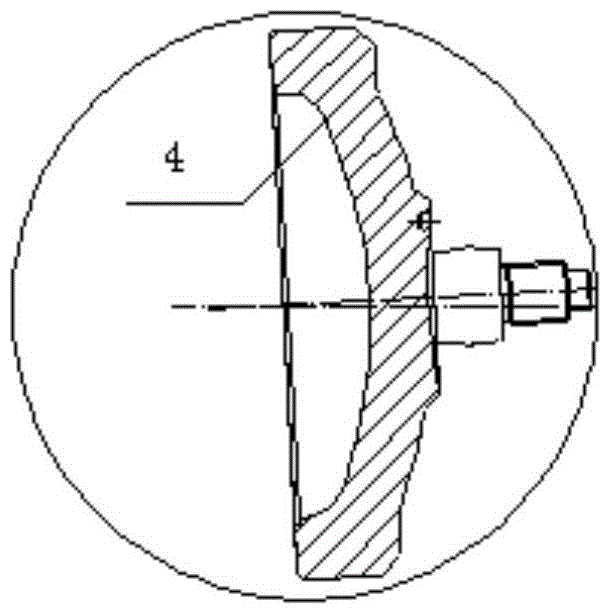

[0033] The valve disc 4 is connected with the rocker arm 5 .

[0034] The valve outlet adopts a trumpet shape to ensure the pressure boundary of the valve shell and to meet the specified maximum flow requirements when fully open.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com