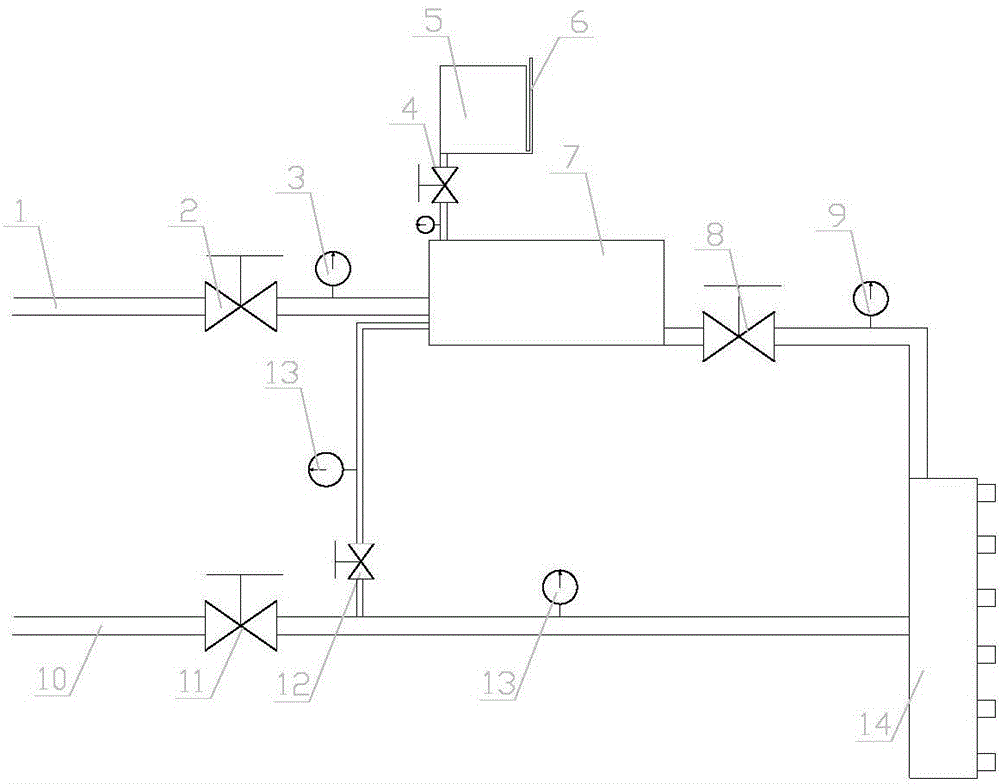

Bubble dedusting system for air dust in mine roadway

A roadway and air bubble technology, which is applied in dust prevention, mining equipment, safety devices, etc., can solve the problems of insufficient dust, poor working environment, and obvious dust removal effect, and achieve the effect of wide source of materials, simple structure, and reduced dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

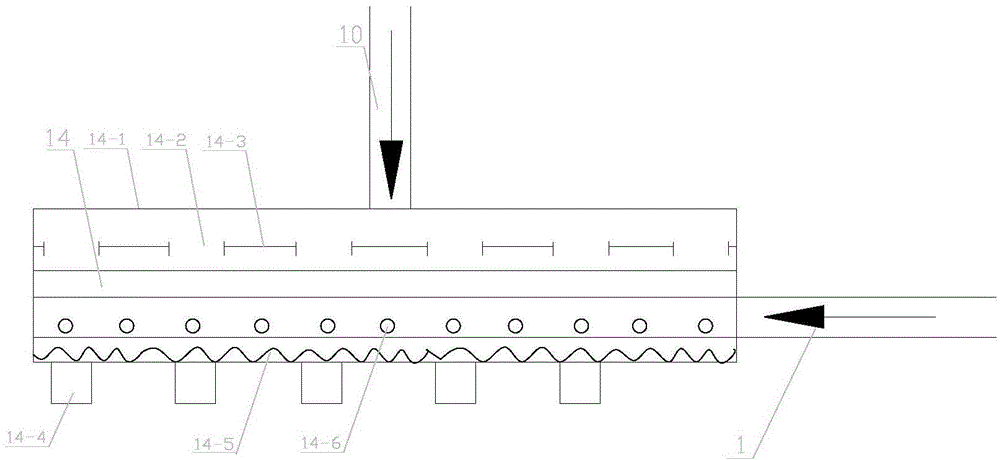

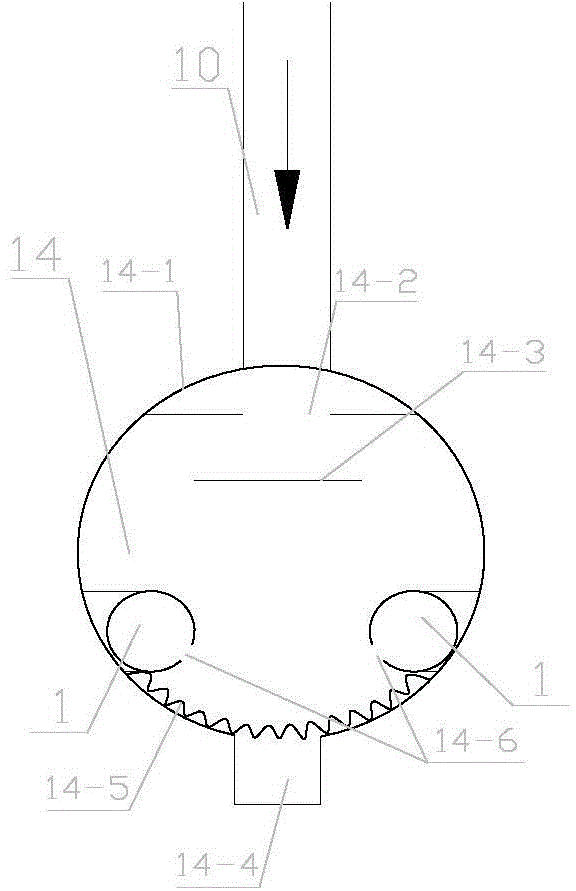

[0020] Air bubble dust removal mechanism: The foaming agent and water are mixed in proportion, the mixed solution and the air flow in the air pipe are mixed in the foamer (14) to form air bubbles (16), and the air flow through the air pipe (1) pushes the air bubbles (16) against the roadway ( 15) Blowing out in the direction of the air flow, the air bubbles (16) collide with the floating dust in the roadway (15) to achieve dust removal, and the air bubbles (16) capture the floating dust in the process of decelerating and accelerating with the air flow. As the number increases, the weight of the corresponding air bubbles (16) increases, and the air bubbles (16) descend and eventually burst. Bubblers (14) are arranged in groups of 3, and each bubbler (14) has a plurality of bubble outlets, forming a large number of bubbles (16) groups in the roadway (15), and its total v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com