Coal processing method and dust suppression device used in its semi-coke dust suppression treatment step

A processing method and a technology of processing steps, which are applied in coking ovens, petroleum industry, and furnace fouling prevention/removal, etc., and can solve problems such as loss of semi-coke products, broken coal blocks, and high powder content of semi-coke products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

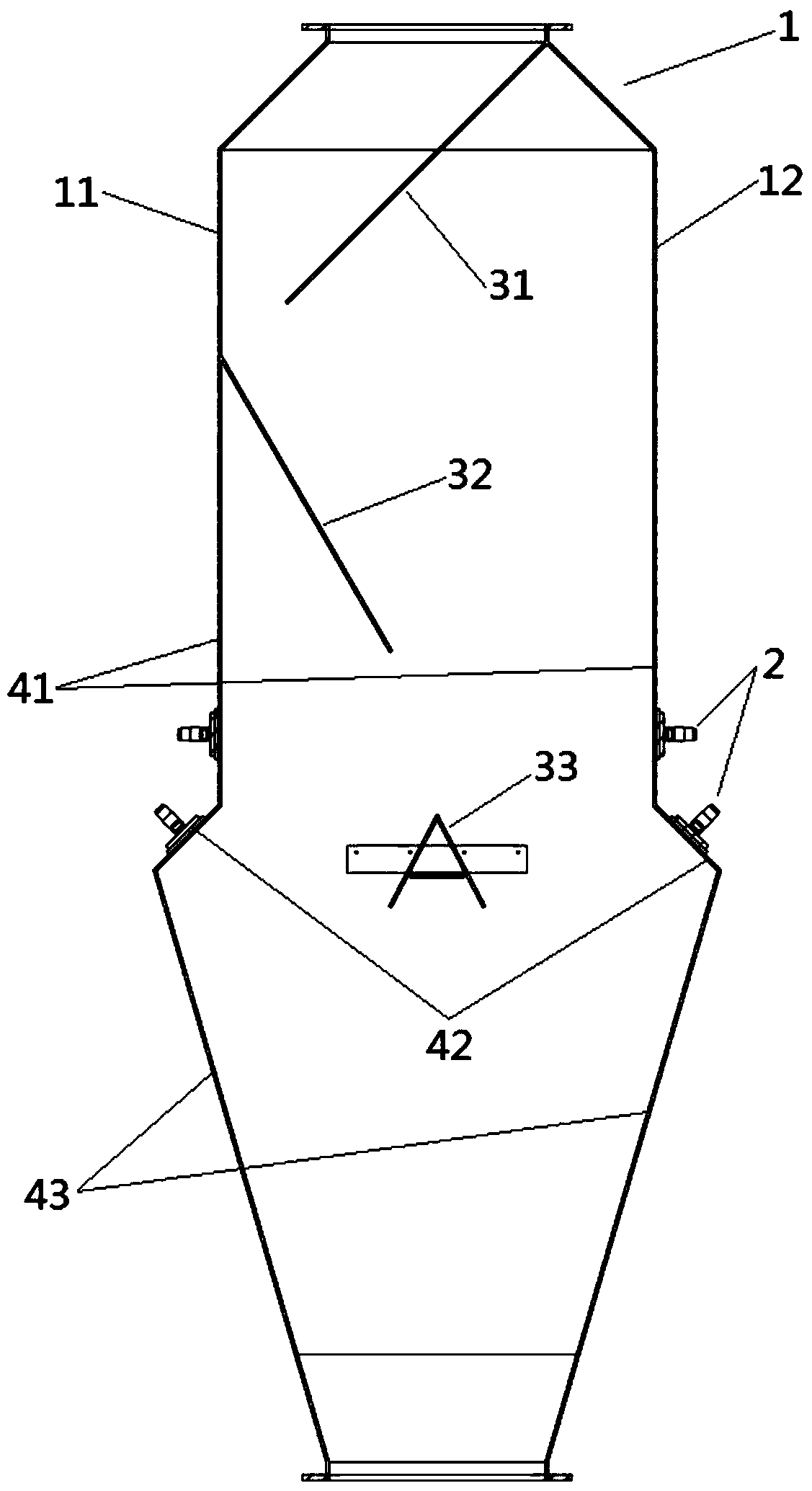

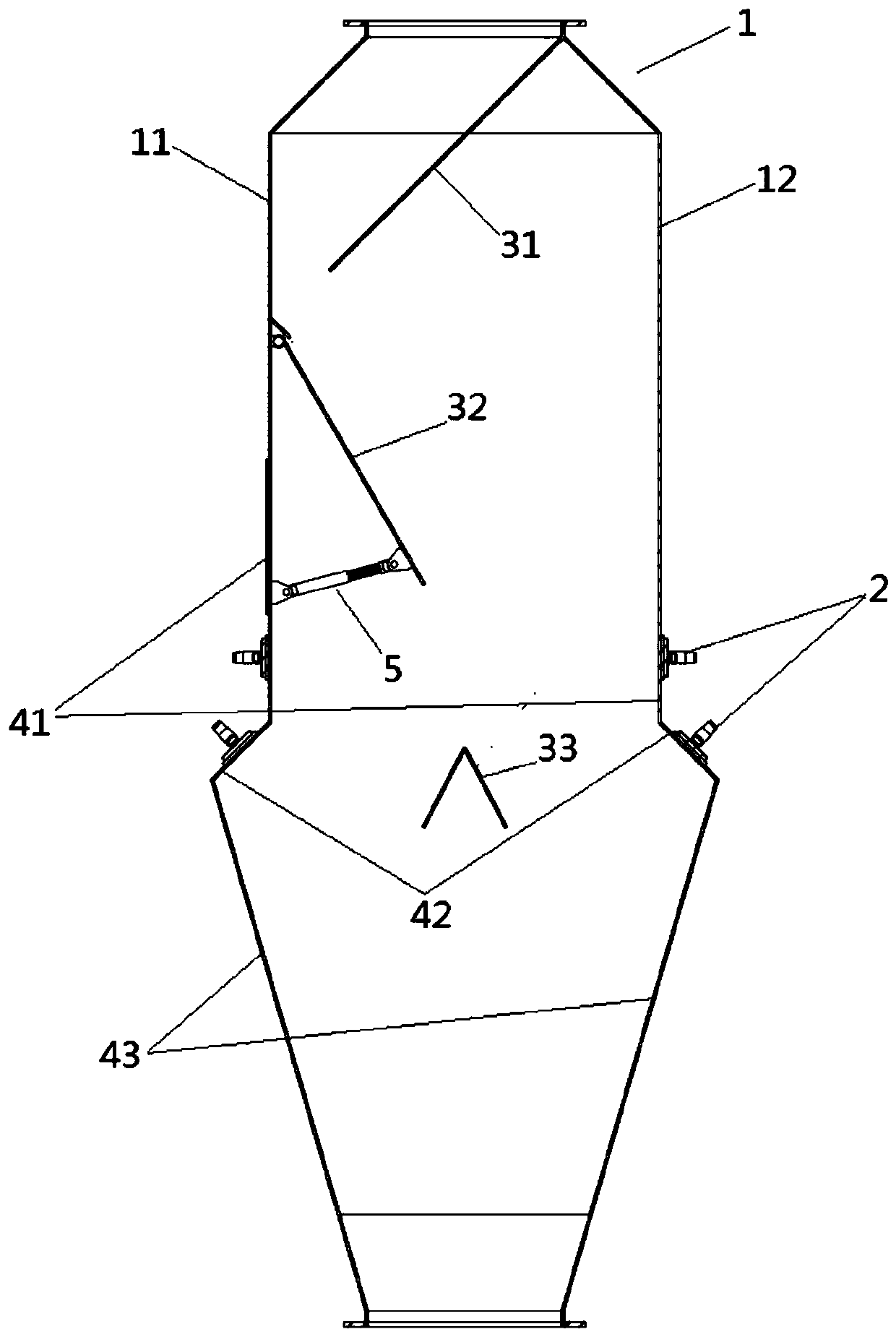

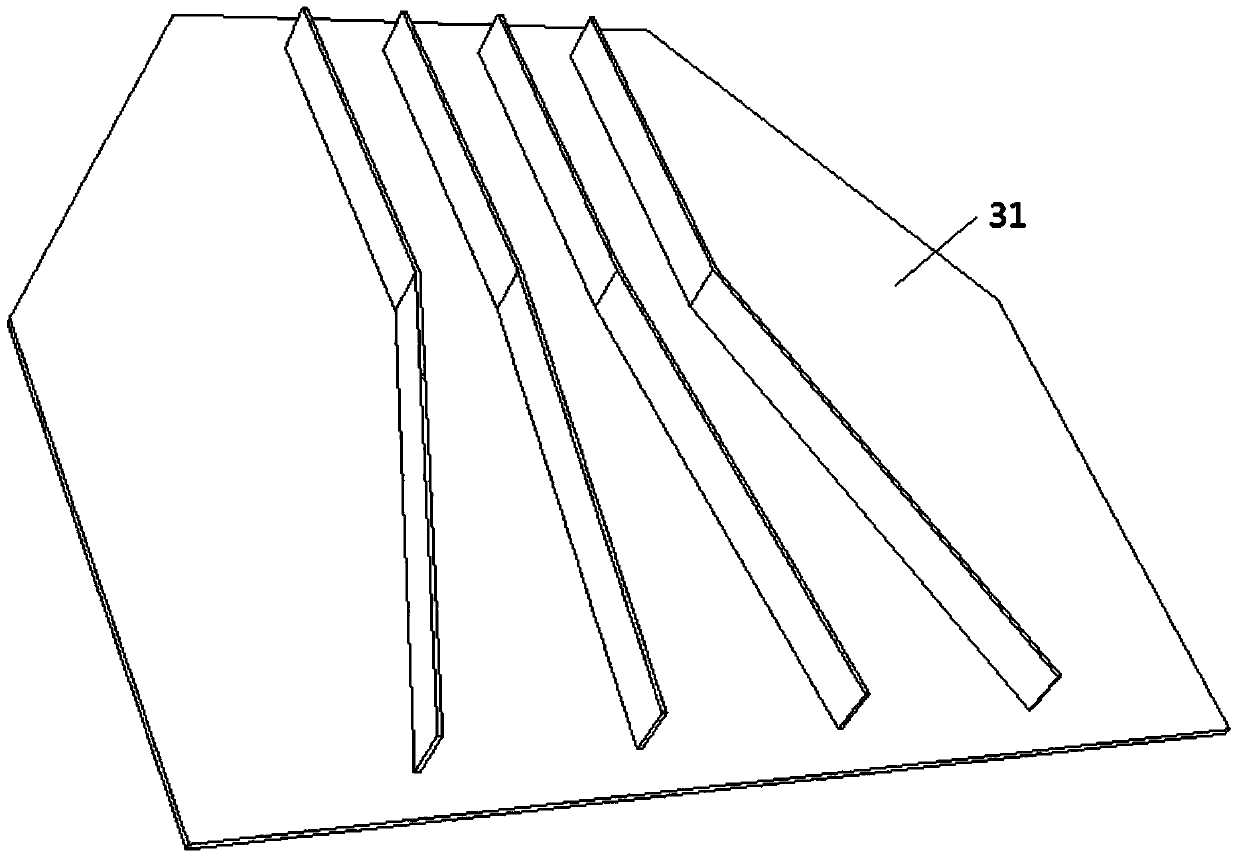

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0037] In the present invention, unless otherwise specified, the used orientation words such as "up, down, left, right" usually refer to the directions shown in the drawings, that is, the directions of the dust suppression device during operation , and should be properly understood in conjunction with the specific descriptions in the text.

[0038] The invention provides a coal processing method, which includes a drying step, a pyrolysis step, a quenching step and a passivation flame-retardant step, wherein the coal processing method also includes semi-coke after the passivation flame-retardant step Dust suppression treatment steps.

[0039] Through the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com