Super stain resistance ultraviolet curing coating

A technology of curing coatings and ultraviolet light, which is applied in the field of ultraviolet light coatings, can solve the problems of anti-fouling effect and easy to be worn, and achieve the effect of maintaining the effect of oil stain resistance and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

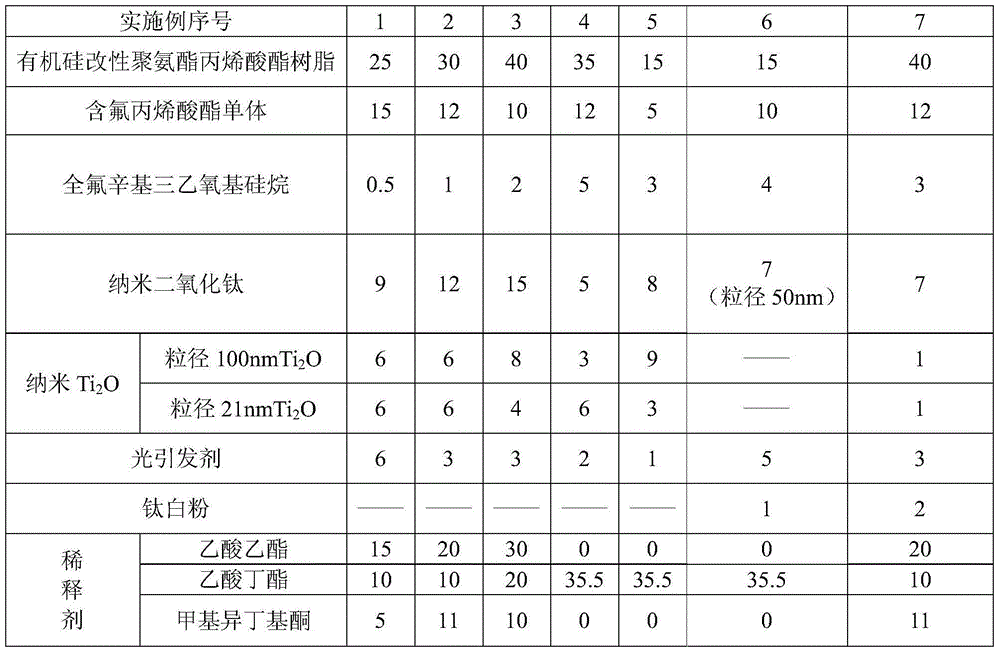

Embodiment 1~7

[0041] The preparation method of embodiment 1~7 ultraviolet curing matte paint is as follows:

[0042] (a) Mix the resin, acrylate monomer, photoinitiator and diluent weighed according to the proportions in Table 1, and stir at 40-50°C for 10-15 minutes at a stirring speed of 400-600 rpm.

[0043] (b) Add the nanoscale titanium dioxide and perfluorooctyltriethoxysilane weighed according to the ratio in Table 1, stir at 800-1200 rpm for 10-15 minutes, and filter with a 300-mesh filter cloth to obtain the product.

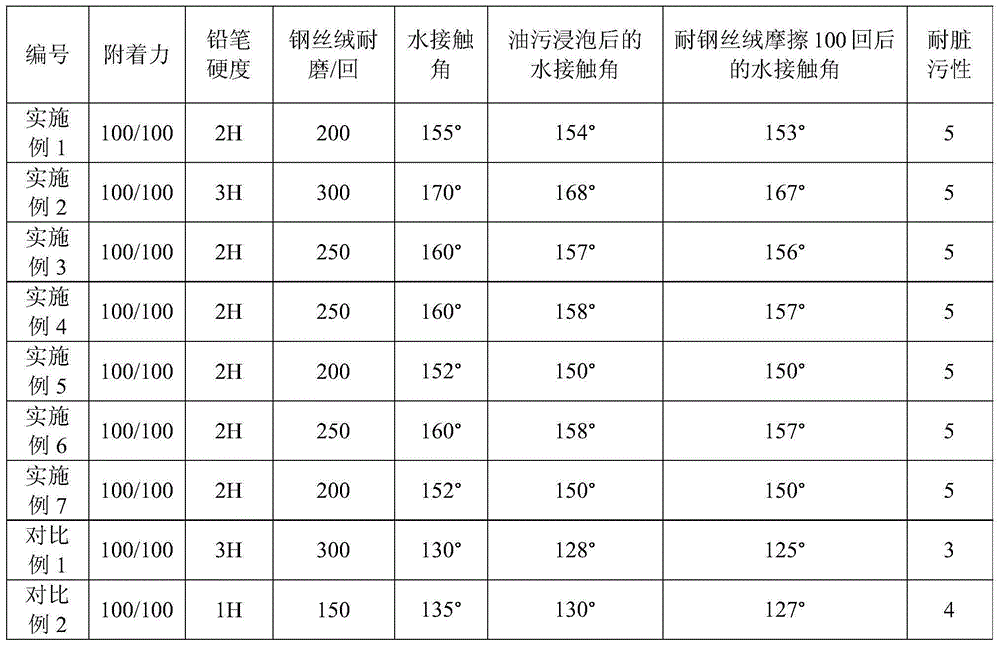

[0044] Embodiments 1-7 The coating and curing method of UV-curable superhydrophobic wear-resistant coatings: the UV-curable paint prepared in Examples 1-7 is sprayed on the PC substrate, and the coating film thickness is 15 microns, 60 ° C Leveling under infrared light for 8 minutes, 800mJ / cm 2 Energy solidified. Spray the UV-curable paint obtained in Examples 1 to 7 to the surface of ABS, PMMA, PC / ABS, glass, metal (stainless steel, magnesium alloy, aluminum alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com