Solvent method synthetic process of Si-75

A technology of propyltriethoxysilane and disulfide disulfide, which is applied in the field of solvent-based synthesis technology, can solve the problems of short product storage period, easy failure, reduced yield, serious pollution, etc., and achieves long storage period, easy operation, good color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

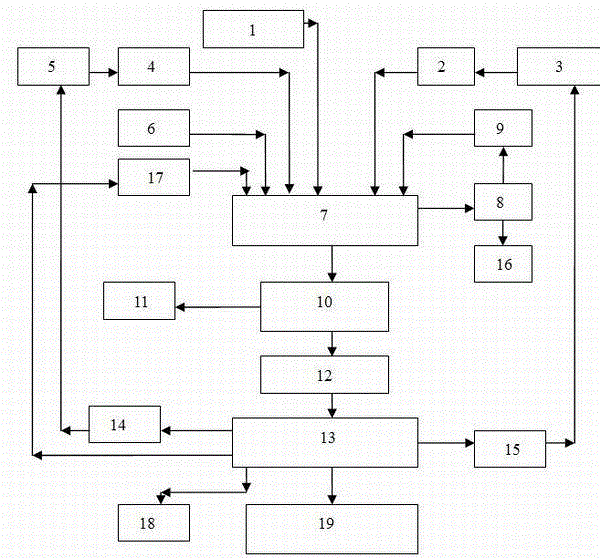

Image

Examples

Embodiment 1

[0021] A kind of solvent method synthetic technique of bis-(Y-propyl triethoxysilane) disulfide, this technique comprises following process steps:

[0022] A. Put sodium sulfide containing 9 crystalline waters and sulfur powder in an equimolar ratio with it into a pond porcelain reactor equipped with a stirrer, reflux condenser, water separator and thermometer; (because sulfur meets iron to form black iron sulfide instead of iron reactors)

[0023] B. Add toluene with a weight ratio of 1.8 times that of sodium sulfide containing 9 crystal water, stir and heat to 80°C to start dehydration, and remove all the water to 110°C to clear the toluene;

[0024] C. Cool to below 50°C, add Y-chloropropyltriethoxysilane with a molar ratio of 2.03 times of sodium sulfide and anhydrous ethanol with an equal weight ratio of toluene, and then add ethylene glycol diethyl ether with 0.4 times the weight of toluene , heated to control the reaction temperature at 95-100°C, and reacted for four h...

Embodiment 2

[0030] 1. A solvent method synthesis process of bis-(γ-propyltriethoxysilane) disulfide, which comprises the following process steps:

[0031] A. Put sodium sulfide containing 9 crystalline waters and sulfur powder in an equimolar ratio with it into a pond porcelain reactor equipped with a stirrer, reflux condenser, water separator and thermometer; (because sulfur meets iron to form black iron sulfide and cannot use iron reactors).

[0032] B. Add toluene with a weight ratio of 1.6 times that of sodium sulfide containing 9 crystal water, stir and heat to 90°C to start reflux dehydration, and remove all the water to 110°C to clear the toluene;

[0033] C. Cool down to below 50°C, add γ-chloropropyltriethoxysilane with a molar ratio of 2.00 times that of sodium sulfide and absolute ethanol with an equal weight ratio to toluene, and then add ethylene glycol diethylene glycol with a weight ratio of 0.3 times that of toluene. Diethyl ether, heating and controlling the reaction te...

Embodiment 3

[0036] 1. A solvent method synthesis process of bis-(γ-propyltriethoxysilane) disulfide, which comprises the following process steps:

[0037] A. Put sodium sulfide containing 9 crystalline waters and sulfur powder in an equimolar ratio with it into a pond porcelain reactor equipped with a stirrer, reflux condenser, water separator and thermometer; (because sulfur meets iron to form black iron sulfide instead of iron reactors)

[0038] B. Add toluene whose weight ratio is 2 times that of sodium sulfide containing 9 crystalline waters, stir and heat to 110°C to start reflux dehydration, and to 110°C to remove all the toluene for clarification;

[0039]C. Cool down to below 50°C, add γ-chloropropyltriethoxysilane with a molar ratio of 2.06 times that of sodium sulfide and absolute ethanol with an equal weight ratio to toluene, and then add ethylene glycol diethylene glycol with a weight ratio of 0.6 times that of toluene. Diethyl ether, heated to control the reaction temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com