Constant-pressure production device for methyl decalactone synthesized spice and production method

A technology for synthesizing methyl decolactone and fragrance, which is applied in directions such as organic chemistry, and achieves the effects of mild reaction conditions, relatively easy process and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

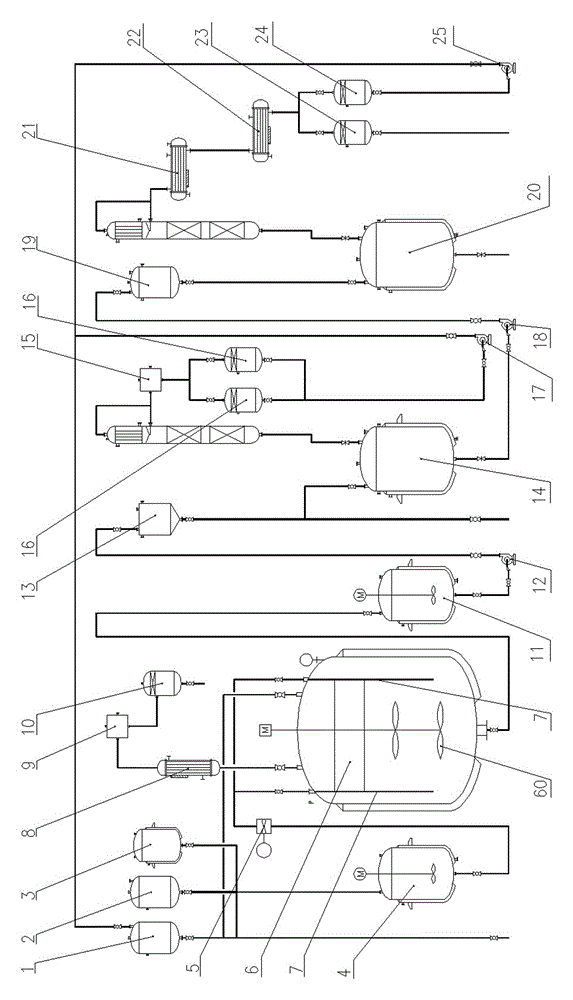

Image

Examples

Embodiment 1

[0041] In this embodiment, secondary octanol and acrylic acid are used as main raw materials, and the by-products are tert-butanol and water.

[0042] a) Put the materials sec-octanol, di-tert-butyl peroxide and acrylic acid into sec-octanol high tank 1, di-tert-butyl peroxide high tank 2, acrylic acid or methyl acrylate high tank 3 respectively , acrylic acid or methyl acrylate head tank 3 maintains a temperature of 20 ± 5 ° C; from the above three head tanks, 100 kg of acrylic acid, 270 kg of sec-octanol, and 15 kg of initiator di-tert-butyl peroxide are put into the batching pot 4, Stir and mix evenly, and control the batching temperature at 20-25°C.

[0043] In this step, the molar ratio of the amount of secondary octanol to acrylic acid is 1.49:1; the molar ratio of the amount of di-tert-butyl peroxide to acrylic acid is 0.07:1.

[0044] b) Metering 550 kg of sec-octanol from the sec-octanol header tank 1 into the reactor 6 as a base material through a direct connection ...

Embodiment 2

[0057] The process of this embodiment is the same as that of Embodiment 1, the difference is that in this embodiment, methyl acrylate is used instead of acrylic acid; by-products are tert-butanol and methanol; the ratio of each raw material is different from that of Embodiment 1.

[0058] Specific steps include:

[0059] a) Put the materials sec-octanol, di-tert-butyl peroxide and methyl acrylate into sec-octanol head tank 1, di-tert-butyl peroxide head tank 2, acrylic acid or methyl acrylate head tank 3 Standby in the middle, the No. 3 high-level tank maintains a temperature of 20±5°C;

[0060] Put 120kg of methyl acrylate, 270kg of sec-octanol, and 20kg of initiator di-tert-butyl peroxide into the batching pot from the above three high-level tanks, stir and mix evenly, and control the batching temperature at 20-25°C.

[0061] In this step, the molar ratio of the batching amount of secondary octanol to methyl acrylate is 1.5:1; the molar ratio of the batching amount of di-te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com