Scissor type lifting tool for plate stacking

A spreader and stacking technology, which is applied in the field of scissor spreaders, can solve the problems of slipping slings, stacking thickness restrictions, and low work efficiency, so as to save stacking and bundling materials, eliminate loose stacking and stripping, and eliminate The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

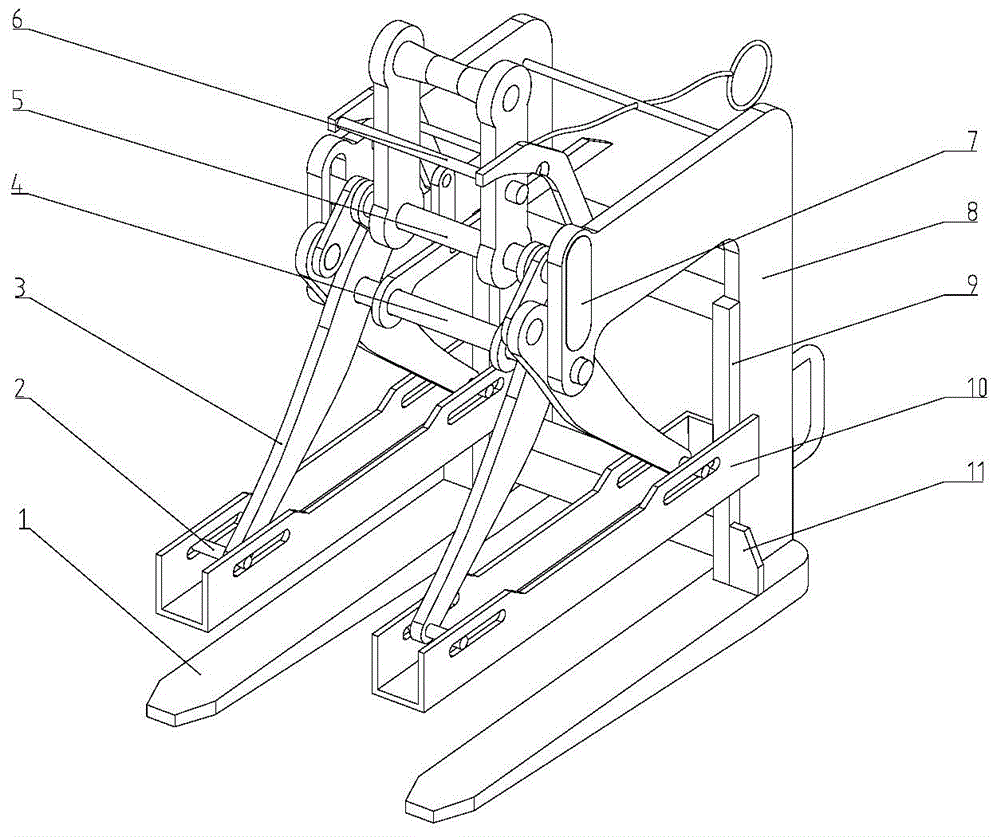

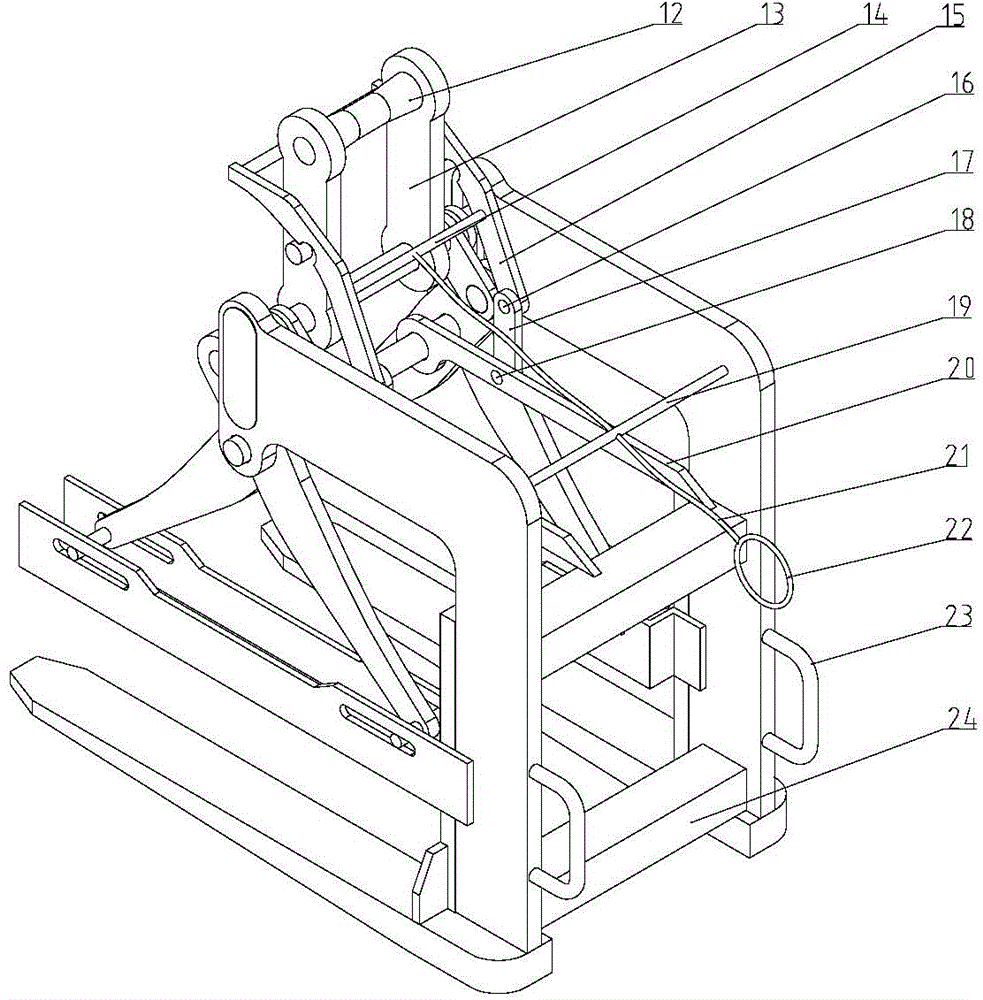

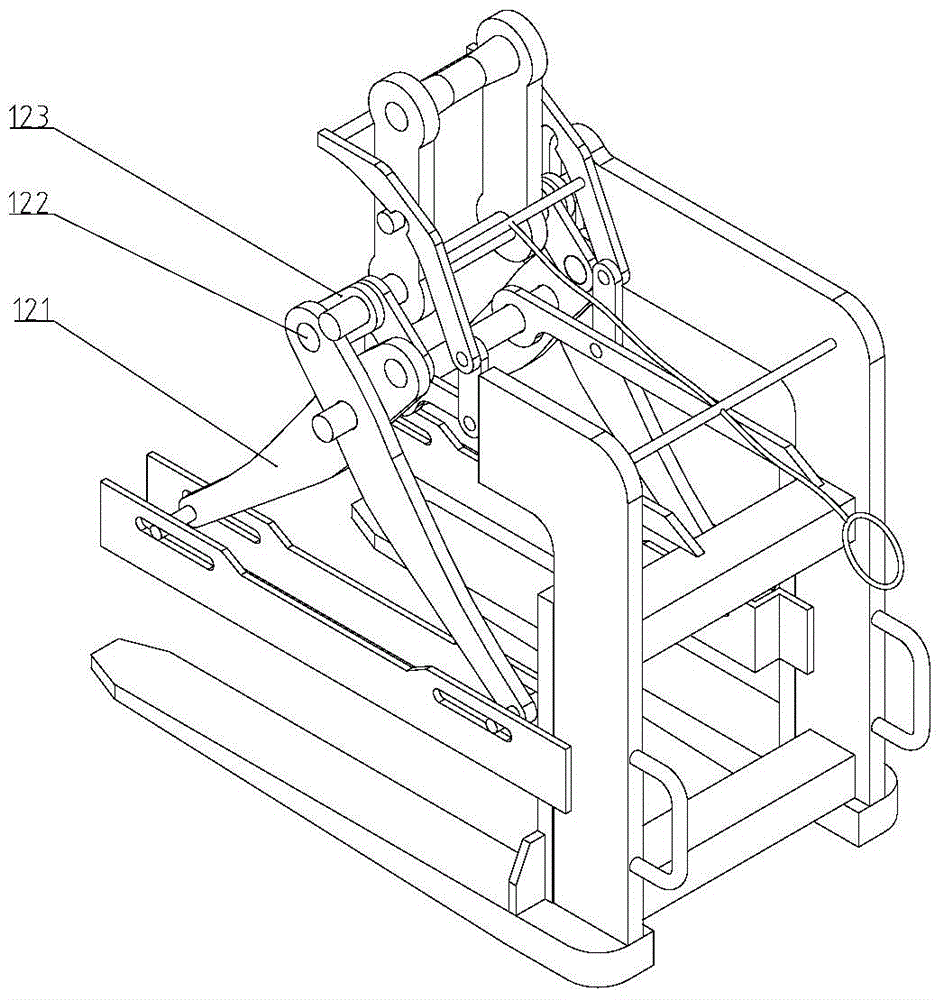

[0028] A scissor spreader for plate stacking, its structure is as follows Figure 1-3 As shown, it is composed of a scissor lever mechanism 3, a main frame, a locking device and a lifting rod. The scissor lever mechanism 3 is composed of two groups of left and right symmetrical linkage mechanisms. The fuselage 8 on the fuselage 1 is composed of the fuselage crosspiece 24 and the push-pull handle 23 arranged on the fuselage 8, and the junction of the fork-shaped bottom plate 1 and the fuselage 8 is also provided with a reinforcing rib 11. The locking device includes a locking bottom bar 20 connected to the top of the fuselage 8, a locking short connecting rod 17, a locking rod 15, an unlocking cable 21 and an unlocking pull ring 22, and the lifting rod 12 is arranged on the top of the fuselage 8 . Each constituent component will be further described in detail below.

[0029] The lower ends of two sets of scissor lever mechanisms 3 are installed in the chute of the groove-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com