Robot claw for supporting ceramic products

A robot gripper and robot technology, applied in the direction of manipulators, conveyor objects, chucks, etc., can solve the problems of lower production efficiency, low versatility, and high production costs, and achieve the effects of improved efficiency, strong flexibility, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

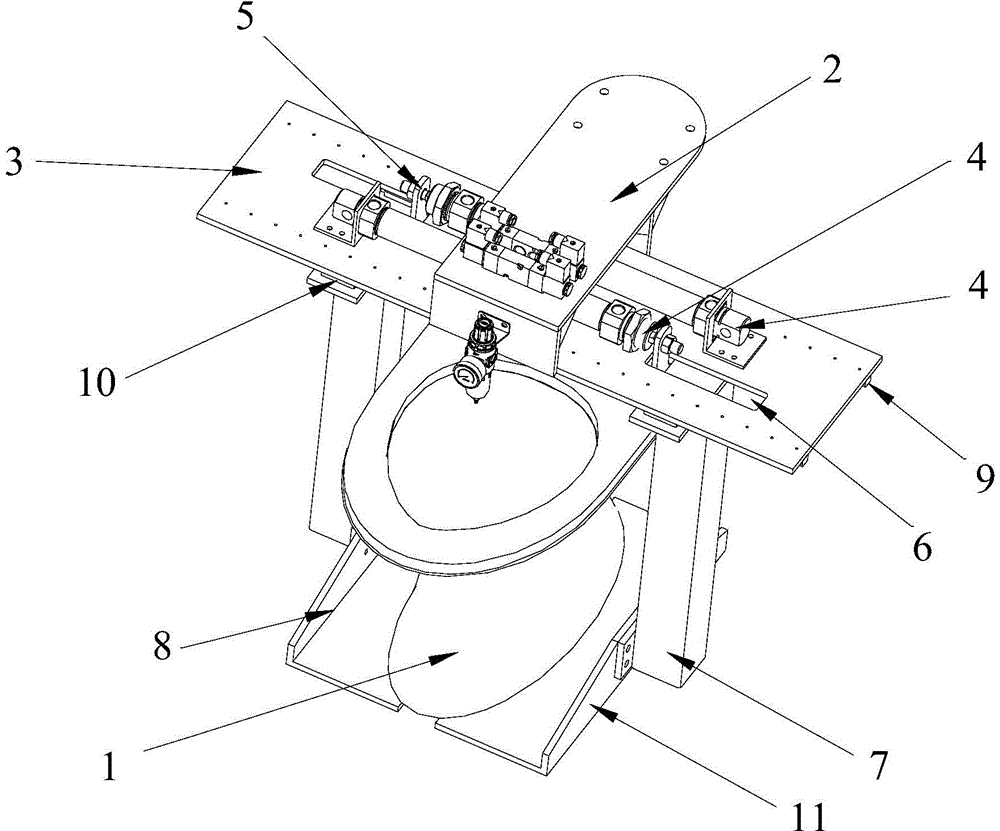

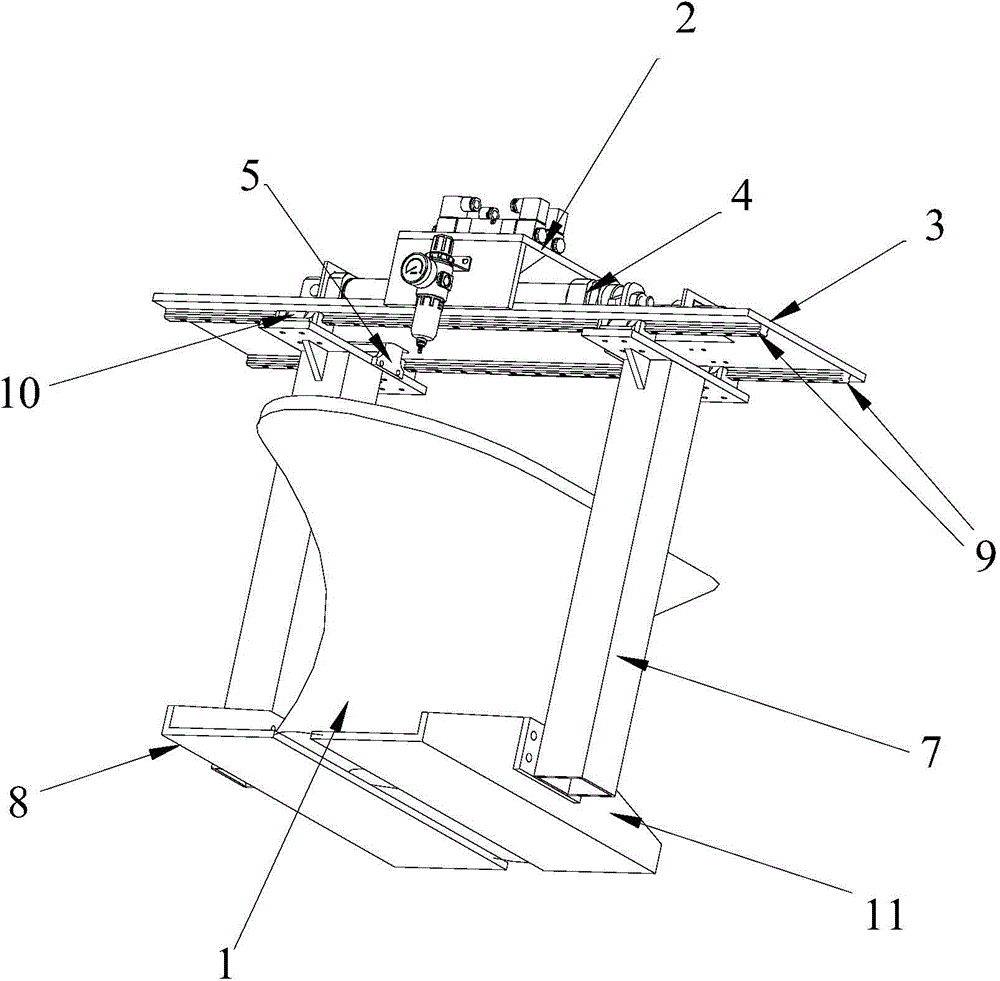

[0024] like figure 1 and figure 2 As shown in the figure, the robot gripper for holding ceramic products of the present invention is installed on the movable end of the robot, and is used to hold the ceramic product 1 for handling; the gripper includes: a bracket 2 connected with the movable end of the robot; The connecting plate 3 , the bracket and the driving device 4 are connected to the bracket 2 . The bracket includes a support arm 7 and a support plate 8 for holding the ceramic product 1. One end of the driving device 4 is fixed on the end face of the connecting plate 3, the other end is connected to the support arm 7, and the other end of the support arm 7 is connected to the support plate. 8 connections. The drive device 4 drives the carriage to reciprocate, and the carriage is slidably connected to the connecting plate 3 .

[0025] The present invention also includes a connecting piece 5 , a movable slot 6 is formed at the other end of the corresponding driving de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com