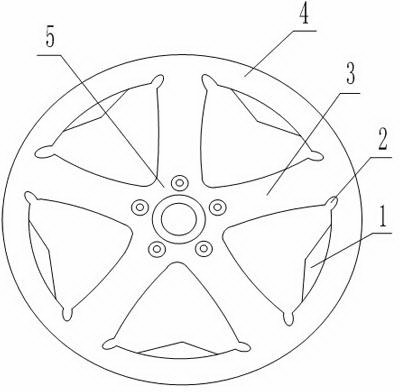

Improved hub structure with flow guide structure at inner side of rim

A technology for rims and hubs, which is applied in the field of improved structure of hubs, can solve problems such as the inability of the hubs to drain water in time, and achieve the effects of reducing weight, avoiding burdens, and avoiding water accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Such as figure 1 As shown, the improved structure of the hub with a flow guide structure inside the rim includes a rim 4, a hub 5 is arranged at the central axis of the rim 4, and one end of the hub 5 in the axial direction is connected to the rim 4 through a spoke 3, and the rim 4 The inner side of the flow structure 1 is provided with a diversion structure 1. The surface opposite the diversion structure 1 and the spoke 3 is a rough slope, and the two slopes intersect. The angle between the two slopes opposite the flow structure and the spoke is set to 150°. 4 A diversion groove 2 is provided at the connection transition point, and the spoke 3, the rim 4 and the diversion groove 2 make a smooth transition, and the distance between the runners 2 on both sides of the same spoke 3 is equal to the minimum width of the spoke 3, and the diversion structure 1 Made of hard aluminum alloy.

[0019] The working principle of the present invention: when the tires of the car are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com