Electric air compressor control strategy and fault diagnosis method

An electric air compressor and fault diagnosis technology, which is applied in the direction of pump control, machine/engine, pump/compressor layout, etc., can solve the problems of no diagnosis and treatment measures, poor adaptability, and low reliability, etc., and achieve improvement Operational efficiency, reduce failure rate, and avoid frequent start and stop effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation of the present invention will be further described below with reference to the description of the accompanying drawings. In the specific implementation, two gas tank air pressure sensors are taken as an example, and three or more air pressure sensors can be referred to for implementation.

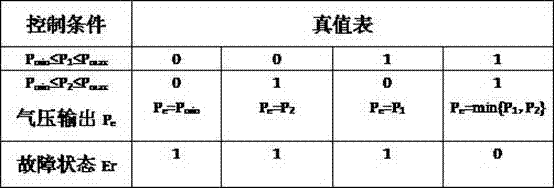

[0034] A control strategy and fault diagnosis method for an electric air compressor, comprising the following specific steps:

[0035] Step (1): Judging and processing the validity of the input signal: the input signal includes: the front air tank air pressure sensor signal, the rear air tank air pressure sensor signal and the unloading signal, the unloading signal is the unloading pressure switch sensor signal Any one of the switching signal or the unloading current signal judged by collecting the working current of the electric air compressor. The air pressure sensor signal of the front and rear air storage tanks is collected by the instrument or other eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com