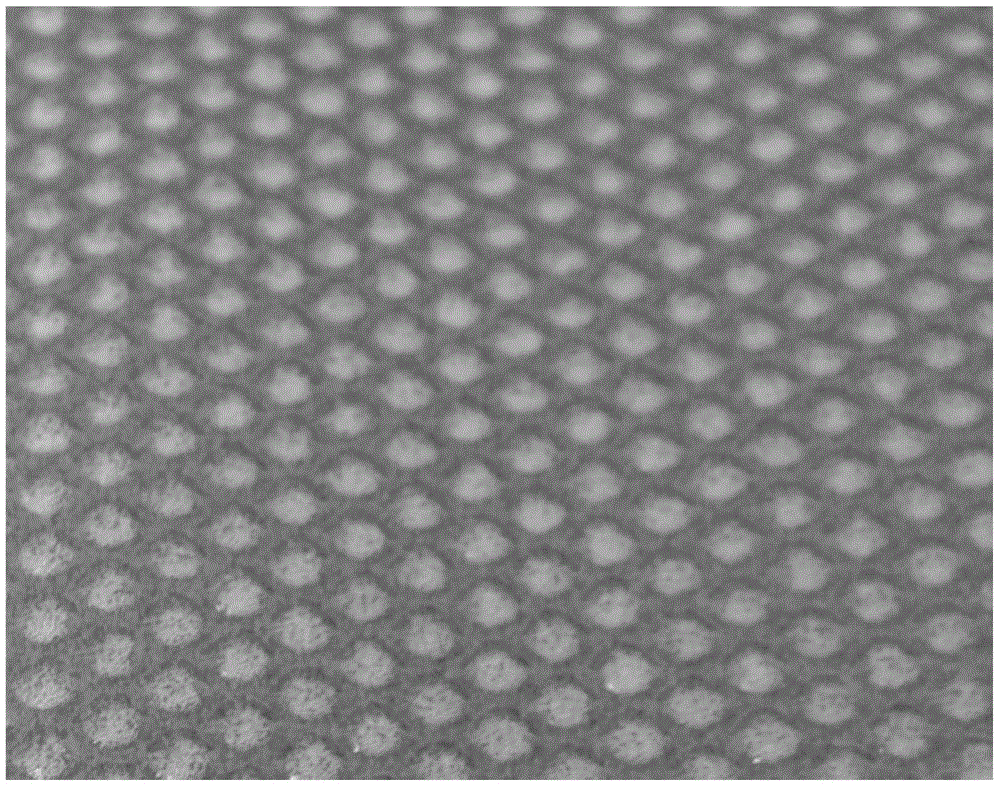

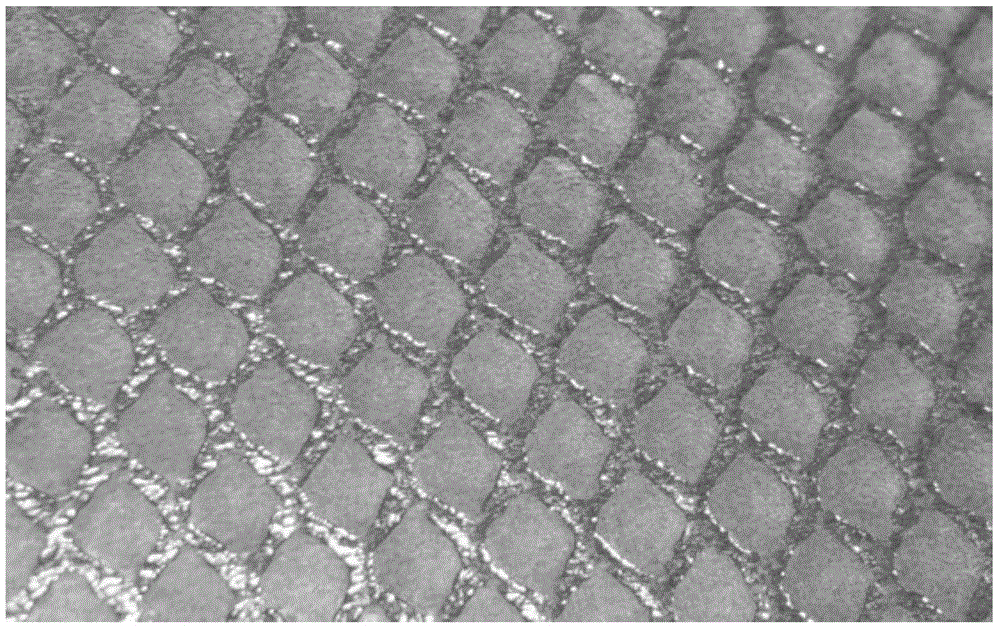

Laminating technology employing latticed adhesive

An adhesive, grid technology, used in adhesives, lamination, lamination devices, etc., can solve problems such as invisible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0113] Unless otherwise specified, all measurements and test parameters were performed under standard conditions familiar to those skilled in the art, ie at room temperature (21°C + / - 1°C) and atmospheric pressure (1 atm).

[0114] In the following experiments, a non-reactive polyolefin-based hot melt adhesive from Jowat AG, Germany ( 238.30).

[0115] The adhesive was applied to the bottom side of a TPO sheet (Benecke-Kaliko / Germany, 2 mm foam with 0.8 mm cover layer) by means of a gravure printing roller, available from the company Hardo (Germany).

[0116] An untextured disc-shaped element (240 mm diameter, 50 mm depth) made of polyoxymethylene (POM) with vacuum holes at the periphery at about 2 cm intervals was used with a single-position vacuum layer using a coated sheet Lamination was carried out using a pressing system from the company Kiefel (Germany) in which the bottom side of the sheet was heated at 180° C. and the top side was heated at 140° C. and the sheet was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com