Adjustable type efficient residue-liquid separation device

A slag-liquid separation and adjustable technology, applied in filtration separation, separation methods, fixed filter element filters, etc., can solve the problems of insufficient practicability, low work efficiency, inconvenient operation, etc., and achieve simple structure and convenient operation. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

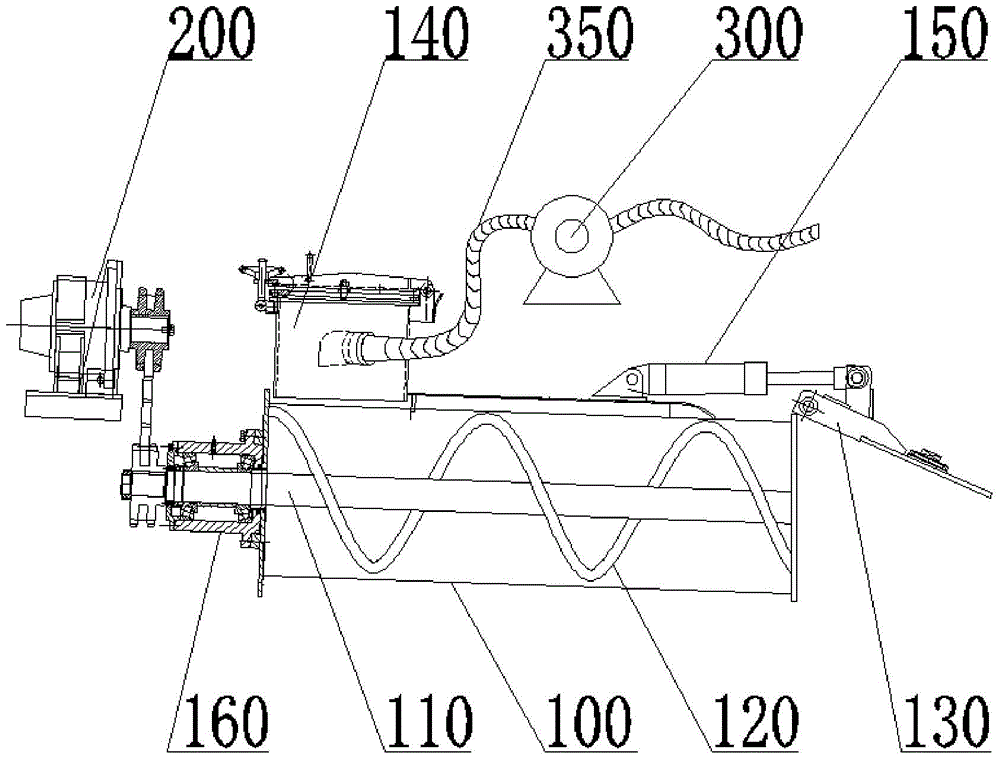

[0044] The first embodiment, refer to figure 1 , The adjustable high-efficiency slag-liquid separation device includes a separation drum 100 and a rotating shaft 110 extending into the separation drum 100. The separation drum 100 is provided with a slag liquid inlet, a filter hole, a slag discharge port, and a slag discharge port for blocking the slag discharge port. The slag liquid inlet is connected with a sewage suction device, the part of the rotating shaft 110 located in the separation cylinder 100 is provided with a screw press blade 120, and the part located outside the separation cylinder 100 is connected with a motor 200, The output end of the screw press blade 120 corresponds to the slag discharge port.

[0045]Wherein, the slag liquid inlet is arranged at one end of the separation cylinder 100, and the slag discharge port is arranged at the other end; The length direction and the circumferential direction are arranged at intervals; the flip cover 130 is hinged on t...

no. 2 example

[0069] In the second embodiment, the implementation principle and the technical effect of the device provided by the embodiment of the present invention are the same as those in the first embodiment. corresponding content.

[0070] In this embodiment, the separation cylinder 100 is in the shape of a truncated cone, including a large end close to the slag liquid inlet and a small end close to the slag discharge port, and the pitch of the screw press blade 120 gradually decreases from the large end to the small end .

[0071] The purpose of arranging the separation cylinder 100 and the screw press blades 120 in this way is that the solid slag is gradually squeezed by the inner wall of the separation cylinder 100 during the process of being pushed by the screw press blades 120 to the slag discharge port, so as to optimize the pressing effect of the screw press blades 120 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com