Cosmetics

一种化妆材料、化合物的技术,应用在化妆材料领域,能够解决无法同时形成乳化组合物等问题,达到保存稳定性良好、良好涂抹特性、优良延展性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0184] Hereinafter, although an Example and a comparative example are shown, and this invention is concretely demonstrated, this invention is not limited to a following example.

[0185] First, Synthesis Examples 1 to 15 of polymers were prepared for use in Examples and Comparative Examples. Synthesis Examples 1 to 8 are paste compositions containing polymers of organohydrogenpolysiloxane and polyoxyalkylene, and Synthesis Examples 9 to 15 are paste compositions containing polymers of organohydrogenpolysiloxane and polyglycerin .

[0186]

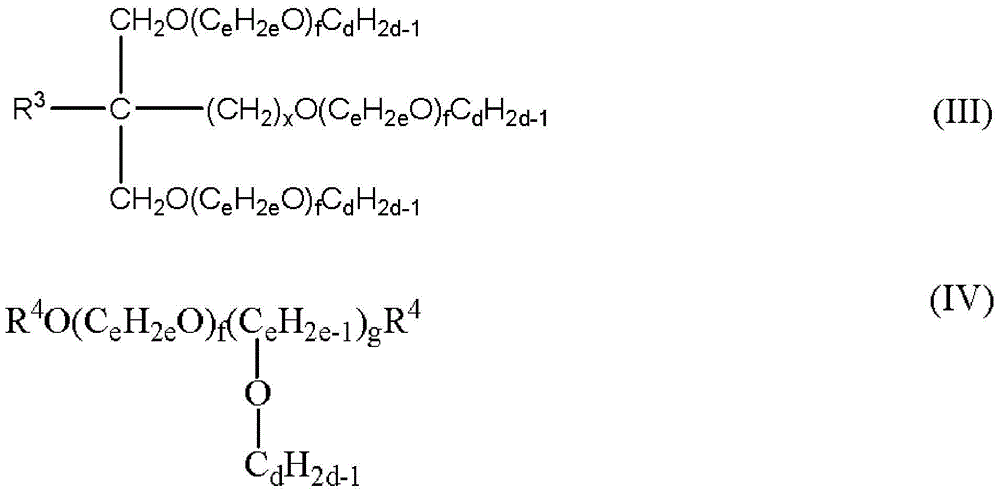

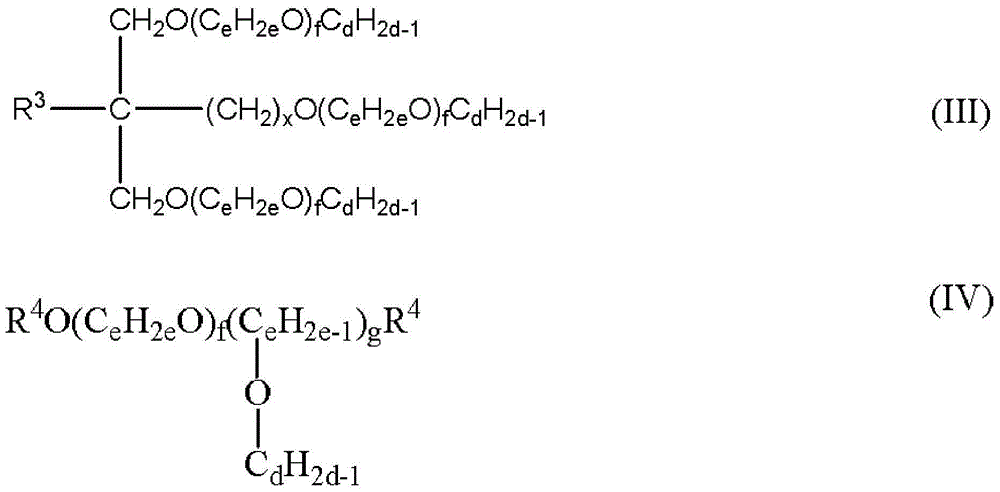

[0187] First, synthesis examples 1 to 8 of polymers containing organohydrogenpolysiloxane and polyoxyalkylene will be described.

Synthetic example 1

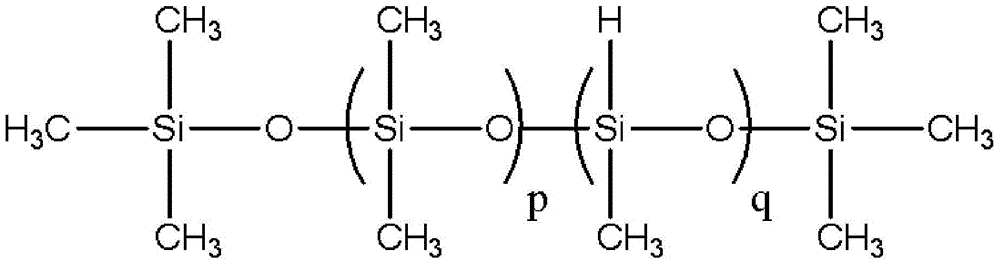

[0189] In the reactor, the average composition formula is 324.2 g of organohydrogenpolysiloxane shown in formula (1), the average composition formula is 53.8 g of polyoxyalkylene shown in formula (2), and the viscosity at 25°C is 6mm 2 162.0 g of dimethyl polysiloxane per s, 270.0 g of ethanol, and 0.3 g of a 3% by mass chloroplatinic acid ethanol solution, the internal temperature was maintained at 60 to 70° C., and after stirring for 2 hours, the solvent was removed by reducing pressure. , to obtain a cross-linked silicone polymer.

[0190] Next, 50 parts by mass of this cross-linked silicone polymer and a viscosity of 6 mm at 25° C. 2 / s of 90 parts by mass of dimethylpolysiloxane was dispersed and mixed, and then sufficiently kneaded under shear force by a three-roll mill to swell to obtain a paste composition.

[0191]

[0192] CH 2 =CH-CH 2 -O-(C 2 h 4 O) 10 -CH 2 -CH=CH 2 (2)

Synthetic example 2

[0194] In the reactor, the average composition formula is 611.4 g of organohydrogenpolysiloxane represented by formula (3), the average composition formula is 113.7 g of polyoxyalkylene represented by formula (4), and the viscosity at 25°C is 10mm 2 483.4 g of dimethylpolysiloxane per s, 600.0 g of ethanol, and 0.5 g of a 3% by mass chloroplatinic acid ethanol solution, the internal temperature was maintained at 60 to 70°C, and after stirring for 2 hours, the solvent was removed by reducing pressure. , to obtain a cross-linked silicone polymer.

[0195] Next, 36 parts by mass of this cross-linked silicone polymer and a viscosity of 10 mm at 25° C. 2 / s of 84 parts by mass of dimethyl polysiloxane was dispersed and mixed, and then sufficiently kneaded under shear force by a three-roll mill to swell to obtain a paste composition.

[0196]

[0197] CH 2 =CH-CH 2 -O-(C 2 h 4 O) 15 -CH 2 -CH=CH 2 (4)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com